Swiss Food Giants Open Facility for Cultivated Meat, Animal-Free Dairy & More

4 Mins Read

Migros, Givaudan, and Bühler Group have opened The Cultured Hub, a biotech facility to speed and scale up the production of cellular agriculture foods.

Three years after announcing the partnership, some of Switzerland’s largest food companies have opened the doors to a factory that will churn out next-gen foods like cultivated meat, cow-free dairy, and cell-based chocolate.

The Cultured Hub, situated in The Valley in Kemptthal, is a biotech plant and scale-up platform that aims to revolutionise the alternative protein sector by speeding up the development and commercialisation of cellular agriculture products.

It is a joint venture between retail giant Migros, flavour specialist Givaudan, and equipment manufacturer Bühler Group, combining “centuries of collective experience” in food processing, product development, manufacturing, marketing, and commercial launches.

“The Cultured Hub represents a paradigm shift in how we approach food production,” said Matthew Robin, CEO of dairy company Elsa Group, a subsidiary of Migros Industries.

“Our jointly developed facility embodies the collaborative spirit of the Swiss food ecosystem,” The Cultured Hub CEO Yannick Gächter said at an event co-hosted by the Swiss Food & Nutrition Valley the day after the launch.

“By bringing together the right partners, our technology platform also enables startups to tap into centuries of experience in food processing, product development, production, marketing and market launches, allowing them to scale up faster and minimise capital investment.”

Tech capabilities for food and beyond

The hub is equipped with advanced production development labs, as well as cell culture and fermentation capabilities and equipment. Its host of partners allows the centre to empower startups to scale up the development of market-ready products that are better for the environment, and at a faster rate.

The tech platform offered by the hub can support the development of cultivated and fermentation-derived products like meat, fish, dairy, pet food, and cocoa. But it’s not just restricted to food – companies can also innovate with materials like cosmetics and select pharma applications.

The Cultured Hub can host three companies at a time, which can work simultaneously in fully separated suites. This helps accelerate market entry by saving time and resources, and allowing the entities to focus on creating the optimal food products at competitive costs.

Additionally, it allows Migros, Givaudan and Bühler Group to expand their sustainability efforts and make the hub a “unique access point” for knowledge, skills, tech, and retail and consumer education.

“As a global leader in flavours, taste, functional and nutritional solutions, with deep expertise in biotech, Givaudan is committed to unlocking new opportunities in the cellular agriculture space and contributing to the transformation of the global food system,” said Fabio Campanile, head of science and tech at Givaudan.

“Through the Cultured Hub, and the ecosystem we are building with start-ups, partners and customers, we look forward to co-creating new, game-changing solutions that meet consumer demand for healthier, more planet-friendly products,” he added.

Startups can scale up without taking financial hits

It’s not just that companies will be able to ramp up their processes from small-scale lab experiments (like shake flasks) to 1,000-litre pilot operations – they’ll be able to do so without investing in expensive assets or diluting equity.

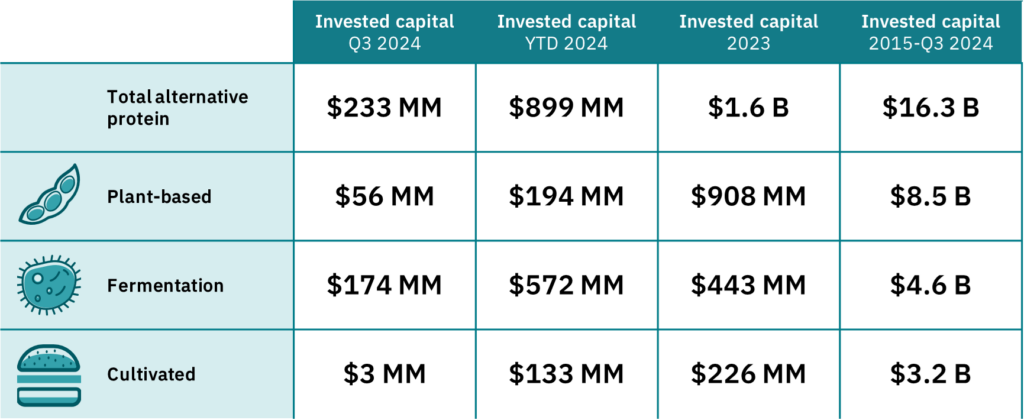

This is critical at a time when money is hard to come by for alternative protein startups – VC investments dropped by 44% last year, with cultivated meat startups alone seeing a 75% decline. And while a recovery was looking likely by the first half of this year, companies in the latter segment only raised $3M in the third quarter, making another annual decrease likely.

The Cultured Hub’s model is said to bridge the gap between research and commercial production, allowing companies to demonstrate and refine their processes efficiently.

“Setting up in Switzerland has helped us to position as a leading scaffold provider for cellular agriculture,” said Simona Fehlmann, co-founder and CEO of Swiss firm Sallea, which spun off from ETH Zurich late last year and recently closed a $2.6M pre-seed round for its plant-based scaffolds for cultivated meat.

“Switzerland is not only home to global companies like Nestlé, Bühler and Givaudan with a wealth of knowledge and expertise in the food sector, it also has a strong pool of talent, which is essential to any startup’s growth.”

Gaechter believes the hub is a “pivotal moment” in the global protein transition. “The opening of this facility is not just an achievement for our team, but a landmark moment for the industry,” he said. “We are excited to open a facility that will enable start-ups to scale up without heavy capital investment and contribute to global food system improvements.”

Ian Roberts, CTO of Bühler Group, added: “The Cultured Hub is designed to bridge the scale-up gap for companies, enabling them to retain equity, protect intellectual property, and fast-track their journey to market without high capital investment.

“We are thrilled to bring together industry players and create a collaborative environment that will drive significant advancements in the industry.