4 Mins Read

Edible peel startup Apeel, which works to eliminate food waste and plastic pollution, has acquired AI hyperspectral imaging tech company ImpactVision, and by integrating this new tech into their application systems at supplier locations around the world, they will be able to help food suppliers and retailers in extending the shelf life of their fresh produce on a larger scale.

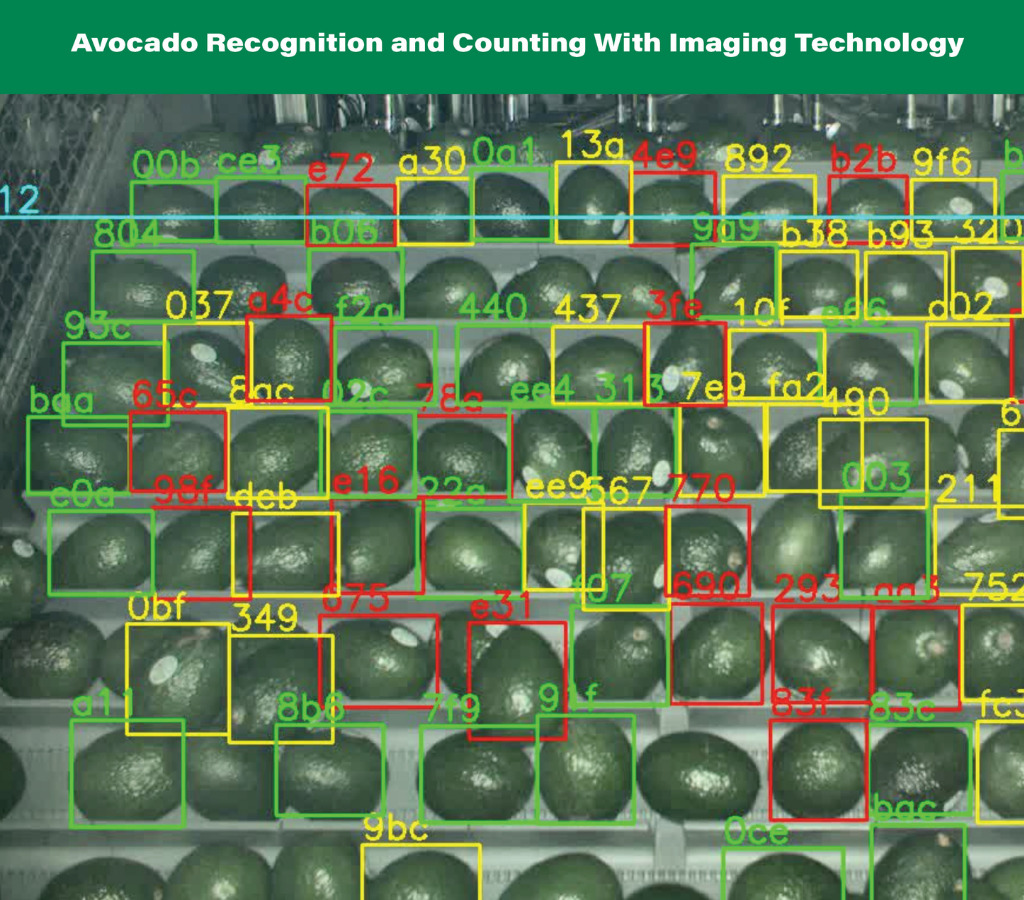

California-based food tech firm Apeel acquired ImpactVision for an undisclosed amount to use the latter’s imaging technology enabling suppliers to literally look inside their produce and understand the interior quality of the items.

Before this, Apeel had developed an edible “peel” technology which helps extend the shelf-life of fresh produce and was recently used by retail giant Walmart to trial plastic-free cucumbers given that the former uses leftover food materials like peel or skin of avocados, limes, apples, etc. and produces a blend that creates a protective layer for the produce. This results in the produce lasting 2x longer than it normally would as the peel slows down the water loss and oxidation that could make the produce go bad.

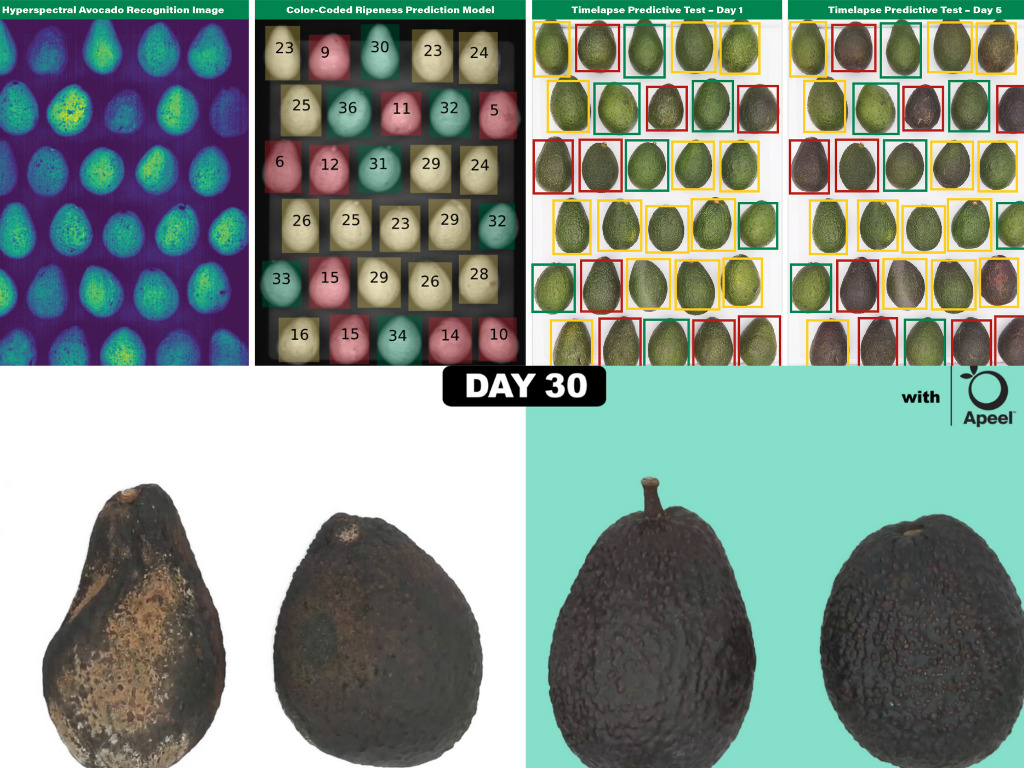

Now with this new technology, the company will be able to assess the quality of products by collecting quantifiable data on ripeness, freshness, nutritional density, and other indicators of the quality of the produce. To understand this, let us take the example of avocadoes. Usually, depending on how they look or feel when squeezed, suppliers and consumers access the ripeness. However, with the new hyperspectral imaging, the technology will be able to collect information from light the human eye can’t see revealing its firmness and dry matter. This helps Apeel to frame a real-time prediction model for avocadoes – red, yellow, green, from ripest to least ripe.

This first acquisition will facilitate the company in its plans of quantifying and digitizing produce quality data for its partners as well as for the entire global food system.

In a press release seen by Green Queen, CEO of Apeel, James Rogers, said: “Our journey began with Apeel’s plant-based protection – an invisible ‘peel’ that addresses the challenge of global food waste by bringing more time to fresh produce before it spoils. Now, we’re expanding our technology to bring to light the previously invisible characteristics of produce, including internal quality, phytonutrient content, and environmental impact.”

We’re expanding our existing technology to bring to light the previously invisible characteristics of produce, including internal quality, phytonutrient content, and environmental impact

James Rogers, CEO of Apeel

Given that its plant-based protection is in use throughout packing and distribution centers across North America, South America and Europe, the imaging technology will be added to the application systems to gather high-quality data images as the produce travels along the conveyance lines.

Founder of ImpactVision, Abi Ramanan, said that its company’s technology can predict the internal quality of food products from hyperspectral images. “When this ability to ‘see beyond the borders of human vision’ is combined with Apeel’s shelf-life extension technology, the potential to fundamentally transform produce supply chains to reduce post-harvest loss, optimize distribution and lengthen shelf-life is enormous.”

At the moment, 40% of the food grown globally goes to waste and hence, by continuously expanding into new produce categories and geographies, Apeel aims to collect category-wide datasets in a presently data-poor food landscape and by providing the largest and most comprehensive database of objective fresh produce insights aims to reduce food waste and strengthen the fresh fruit and vegetable supply chains.

When this ability to ‘see beyond the borders of human vision’ is combined with Apeel’s shelf-life extension technology, the potential to fundamentally transform produce supply chains to reduce post-harvest loss, optimize distribution and lengthen shelf-life is enormous

Abi Ramanan, Founder of ImpactVision

For instance, fresh produce suppliers can use this data and know the exact ripening window for all their items, say if a produce supplier sees that an avocado is set to ripen tomorrow while another one will take 4 days to ripen, they know that one has more time to travel and should be sent to the retailer that is further away, ensuring that the best quality reaches consumers.

Presently, Apeel has 30 supplier integrations, with plans to double this number by end of this year.

Rogers added that using the insights made available through Apeel’s imaging technology, its partners will be able to effectively ‘see’ inside of every fruit and vegetable. “This will help quantify quality as never before so that the distribution of fresh food can be optimized. For our partners, this will mean less waste and an immediate bottom-line improvement, and ultimately, the ability to one day differentiate produce by making freshness and nutritional content ‘visible’ to the consumer.”

Elsewhere, China has introduced a new legislation to tackle food waste that bans online binge-eating videos and fines people that leave excess uneaten food in restaurants to enable a ‘resource-conserving’ society.

Another company that is using its tech to enhance the shelf-life of products is Hazel Technologies, whose product offering is a sachet that releases shelf-life enhancing vapours in bulk produce cartons and recently received US$70 million in an oversubscribed Series C financing round to expand this technology.

Elsewhere, Barry Callebaut, which manufactures chocolate and cocoa products unveiled a sustainable brand Cabosse Naturals that is made from one single ingredient cacao which otherwise is wasted as only 30% of the entire pod is used in conventional products leading to unnecessary food waste.

Lead image courtesy of Apeel.