3 Mins Read

Researchers have developed a new form of cultivated meat using a novel technique, which they say allows for a more natural and realistic flavour and texture. The new method involves stacking thin layers of muscle and fat cells that have been cultured in labs, which can produce realistic “slabs” of meat and can even be “tuned” to replicate the marbling of real cuts of its conventionally produced counterparts.

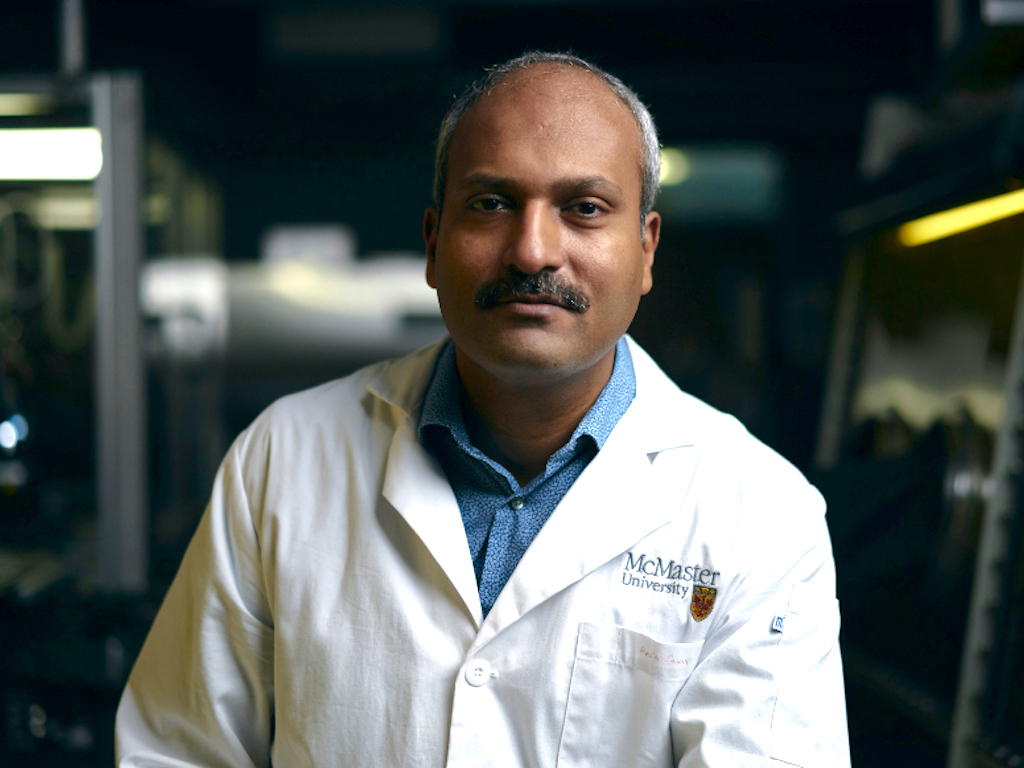

Scientists at McMaster University in Canada have come up with a new way of producing cell-based meat that is far more realistic than current alternative proteins. The study, conducted by Ravi Selvaganapathy and Alireza Shahin-Shamsabadi of the School of Biomedical Engineering, finds that stacking sheets of living cultivated fat and muscle cells – about the thickness of average printer paper – will allow the sheets to naturally bond together into a “slab” of meat.

The cells are first grown in culture and concentrated on growth plates before being peeled off and folded or stacked, a modified technique that was originally used in growing tissue for human transplants.

Consumers will be able to buy meat with whatever percentage of fat they like – just like they do with milk.

Ravi Selvaganapathy, Co-Author, McMaster University

“We are creating slabs of meat,” said co-author Selvaganapathy, who added that these layers can even be “tuned” to change the fat content or replicate the marbled appearance and bite of real cuts of steaks, opening up new avenues to customise cell-based meats.

“Consumers will be able to buy meat with whatever percentage of fat they like – just like they do with milk,” Selvaganapathy explained.

The researchers first proved the concept by making meat using lines of cells from mice, before going onto developing meat cultivated from the cells of rabbits using this technique, which they tested themselves.

“It felt and tasted just like meat,” said Selvaganapathy, who explained that the same technology could be applied to more conventional animal cells, such as cultivated beef, pork and chicken.

This layer-by-layer self-assembly and stacking process is fast (4 days of culture to form sheets and few hours for assembly) and scalable.

Ravi Selvaganapathy & Alireza Shahin-Shamsabadi, McMaster University

In addition, the researchers found that this method could be used for large-scale production too, which they noted will be crucial for cultivated proteins to be able to meet the growing and unsustainable demand for animal meat.

“This layer-by-layer self-assembly and stacking process is fast (4 days of culture to form sheets and few hours for assembly) and scalable,” the authors wrote in the paper, which was published in the journal Cells Tissues Organs.

Selvaganapathy and Shahin-Shamsabadi revealed that they are now in the process of setting up a startup to use their technology to produce cell-based meats and eventually sell it commercially.

So far, the only other food tech that has managed to launch its cultivated proteins on the market is San Francisco-based startup Eat Just, who gained the world’s first regulatory approval from Singapore authorities for its cultured chicken bites in December 2020.

Lead image courtesy of McMaster University.