ProteinDistillery Breaks Ground on Beer Waste Protein Factory in Ceremony Featuring German Politicians

5 Mins Read

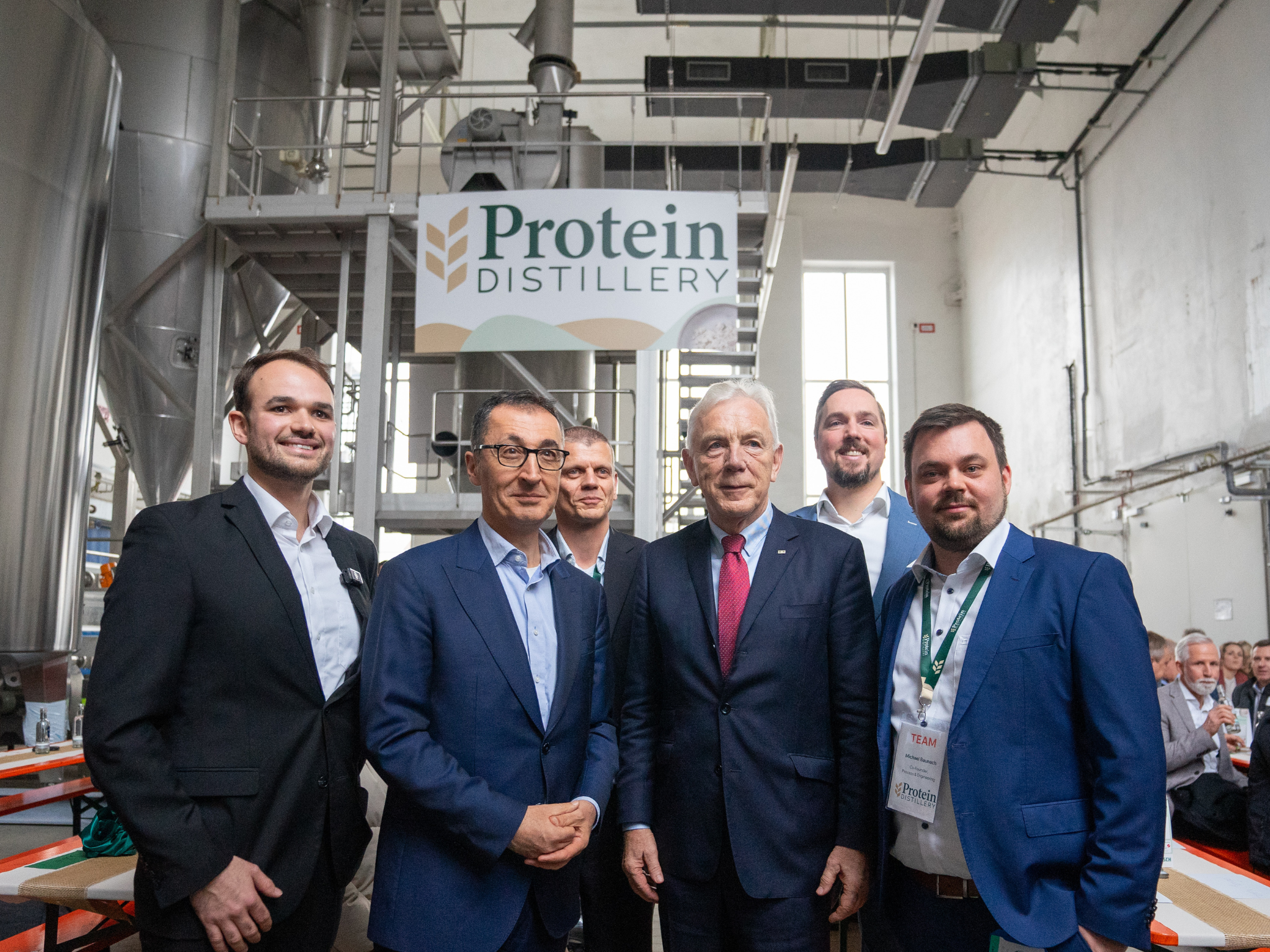

German startup ProteinDistillery has begun construction of a large-scale plant for its yeast-derived Prew:tein ingredient, in a ceremony attended by the federal agriculture minister.

Politicians, artists and footballers were all present at the commencement ceremony of an upcoming factory in southwest Germany that will churn out 200 tonnes of protein made from upcycled beer waste.

Berlin-headquartered ProteinDistillery broke ground on its Protein Competence Center last week, which will produce Prew:tein, a yeast-based protein that can enhance the functional properties of meat and dairy alternatives, and act as an egg white replacement in several applications, including baked goods.

The startup’s patented technology allows it to use several food industry sidestreams, but it has started with brewer’s yeast, an often underutilised byproduct of beer production. This undergoes a fermentation process to turn into Prew:tein, which can act as an emulsifier, a gelling and foaming agent, and a binder to replace animal proteins and plant-based additives like methylcellulose in a host of products.

ProteinDistillery’s facility will be situated at Unilever’s Knorr Campus in Heilbronn, with the ceremony attended by German food and agriculture minister, Cem Özdemir, the city’s head mayor Harry Mergel, and member of parliament Zoe Mayer, alongside artist Tim Bengel and former VfB Stuttgart goalkeeper Timo Hildebrand (who jointly own vegan restaurant Vhy! in Stuttgart).

“With the Protein Competence Center in Heilbronn, we are taking an important step toward establishing sustainable and locally produced proteins that are resource-efficient and independent of agricultural land. This brings a real revolution to the food industry,” said ProteinDistillery co-founder and managing director Marco Ries.

“Turning what’s left from brewing beer into valuable plant-based protein is future-forward. And it hits the spirit of the times: while meat consumption is decreasing, demand for and variety in alternative plant-based proteins are increasing,” added Özdemir.

How Prew:tein addresses multiple alt-protein pain points

The startup uses a process called biomass fermentation, which taps into the high-protein content and rapid growth potential of microorganisms to produce large amounts of food. This allows companies to use the entire biomass produced by the microbes as an ingredient. It’s the same way Quorn has been making its mycoprotein for decades.

ProteinDistillery works with suppliers to source its brewer’s yeast, which is turned into functional building blocks and then recomposed to meet consumer needs. The “gentle processing” involved ensures a clean, native protein that replicates the functionality of animal proteins without compromising on the taste or nutritional value.

The advantages of making food this way are manifold. There’s the environmental impact: relying on microbes instead of water-guzzling, land-intensive livestock means Prew:tein requires 400 times less land and 250 times less water than beef, while producing 80 times fewer greenhouse gas emissions.

But more crucially for consumers, Prew:tein offers functional benefits to enhance plant-based meat, dairy and bakery products. It has a protein content of over 75%, with a digestibility score of 1.0, the highest possible score and on par with egg proteins and milk proteins like casein and whey.

Its binding properties and ability to gel irreversibly even at low concentrations allow producers to give products like vegan burgers and schnitzels a more realistic flavour and texture, while its emulsification and solubility attributes make it ideal for improving consistencies in alt-dairy products, such as harder and better-melting vegan cheese.

Meanwhile, it can provide foaming and emulsion stability in baked goods like muffins and cakes, without the price and market volatility of eggs or the taste and moisture challenges of non-dairy whipping creams. Prew:tein is said to improve the texture, viscosity and firmness of bakery mixes, create stability at hot temperatures, and contribute to a longer shelf life too.

German food minister calls for EU-wide protein strategy

To demonstrate these capabilities, Vhy! introduced Maultaschen (a dumpling filling) at the ceremony, which is the first consumer product made from Prew:tein. This will benefit from a streamlined production process, enabling faster production at lower costs and allowing Vhy! to begin supplying plant-base dishes to local canteens at companies like Porsche and Daimler.

The Protein Competence Centre will begin production in April, helping avoid nearly two million kg of emissions. “On a footprint of less than 1,000 square meters, we will be producing as much protein as found in 20 million chicken eggs,” revealed Christoph Pitter, co-founder and managing director of ProteinDistillery.

The startup, which raised €15M ($15.8M) in seed funding in March, chose Heilbronn as the region is known as a key research and production hub, and hopes to “promote exchange between science and industry” with the new facility.

“Our agricultural and food industries are full of innovative potential, as shown here at ProteinDistillery,” said Özdemir. “To promote such innovative approaches, we’re evolving our plant protein strategy into a broader protein strategy. I’m also advocating in Brussels for the Commission to strengthen local protein supplies with an EU-wide protein strategy.”

The next few months will see ProteinDistillery focus on installing the remaining equipment, with technical assembly and electrical installations scheduled for early 2025. It also plans to valorise its own sidestreams, with the new plant allowing these to be scaled up from the lab stage too.

These efforts will further strengthen what is already Europe’s largest market for vegan food, representing 40% of the continent’s trade as sales of plant-based meat and dairy reached €2.2B last year (an 8% annual increase). In fact, more than a third of households bought these products in 2023.

Other startups upcycling brewer’s yeast into sustainable ingredients include Dutch player Revyve, which recently unveiled its own egg replacer, and France’s Yeasty, which has discovered a way to remove the bitterness from brewer’s yeast, producing a flour for alternative protein, pet food, and nutrition products.