Prolific Machines Nabs $55M to Create Cultivated Meat & Novel Proteins by Harnessing Light

6 Mins Read

Californian biotech startup Prolific Machines has closed a $55M Series B1 round for its photomolecular platform, which leverages light to create novel proteins at significantly lower costs.

The $55M investment represents the first close of Prolific Machines’ Series B round, and was led by Fonterra’s VC arm The Ki Tua Fund. BreakthroughEnergy Ventures, Mayfield, SOSV, Shorewind Capital, Darco Capital, Conti Ventures, In-Q-Tel (IQT), and several others participated as well.

This means the company – which has previously set out its intention to raise a $170M full Series B round – has so far brought in $86.5M in total investment. Investors in its last round in 2022 included the likes of Shark Tank’s Mark Cuban and model and actress Emily Ratajkowski.

Since being founded in 2020, Prolific Machines has developed a photomolecular biology platform to grow and control cells with light, allowing manufacturers to create products across cellular agriculture for the food and medicine industries. It will use the Series B1 capital to commercialise this platform through industry partnerships.

“Photomolecular biology is the use of light and AI to precisely control and optimise cellular behaviour to more efficiently produce superior bioproduct solutions across wide-ranging applications, from food to pharmaceuticals,” co-founder and CEO Deniz Kent tells Green Queen.

“We set out with a vision to use one of our most abundant resources – light – to create an exponentially better way to control biology,” he says, suggesting that this control is “critical to making cheaper and higher-quality products”.

How does Prolific Machines harness light to create proteins?

Prolific Machines argues that current cellular biology processes are constrained by “expensive, inefficient, and imprecise molecular methods”. But the precision of light allows it to control these processes in “fundamentally new ways”.

“Prolific harnesses light to produce everyday essentials more efficiently, from food and lifesaving drugs to novel biosolutions,” explains Kent. “We use light as a signal to control cellular behaviour with unprecedented precision and instantly instruct cells on what to do, and where and when to do it. Our process creates significant cost, speed, yield, and quality advantages compared to existing processes.”

The company’s technology is inspired by the field of optogenetics, a combination of genetic and optical methods to control the activity and behaviour of cells through light.

“We use ‘non-ionising’ light at relatively low intensities in our process, which means it doesn’t carry enough energy to harm living cells. It is safe for use in the production of both food and non-food products,” says Kent.

How can light improve existing production techniques?

“Methods currently used to make bioproducts are limited to imprecise, inefficient, and expensive control levers – like temperature, chemicals, and proteins – to indirectly control cells,” Kent says. “Prolific’s first-of-its-kind photomolecular platform brings together safe and effective tools – light, bioengineering, hardware, and AI – to unlock unparalleled control and precision.”

He explains that living organisms can sense light because of light-sensitive proteins (LSP), which are naturally occurring proteins found in everything from plants and bacteria to human retinas. These exist to detect and respond to light, and can do this very quickly, causing action in cells within seconds.

“Proteins are at the heart of everything a cell does, from perceiving signals from other cells to switching genes on or off. By attaching LSPs to proteins that you want to control within the cell, Prolific makes it possible to precisely control subcellular biology using light,” he says. When met with light, which acts as a signal, the LSPs can control cells across key functions.

“Prolific unlocks dynamic control by pulsating light in specific patterns, intensities, and wavelengths to activate cellular functions when and where it matters most, which is a game-changer for biotechnology,” adds Kent.

What kind of products can Prolific Machines create?

So what kind of products can you produce using light? “Prolific is co-developing the future of biology with innovators across cultivated meat, nutritional and therapeutic proteins, disease models, tissue engineering, cell and gene therapy, and beyond,” he reveals.

“Examples include nutritional proteins used in supplements and infant formula, antibodies to treat diseases, whole cuts of cultured meat, higher fidelity disease models, and other innovations never before possible.”

Kent calls the process a “boon” for cultivated meat, with companies able to achieve “massive cost, scale, and sterility benefits without the need for recombinant proteins or growth factors”.

“Using light, our process can create structured or marbled products, like steaks. We can create all cuts of meat that would be impossible to make in a scalable manner with existing cultivated production methods,” he says. “Our process provides unparalleled spatial control, creating the patterning and structure to make alternative protein products with first-of-its-kind texture, taste, and affordability.”

As for “nutritional proteins”, this could entail many “high-value proteins”, including those found in infant formula, such as lactoferrin (whose precision-fermented version has only recently been commercialised).

Can light help make cultivated meat cheaper?

Prolific Machines suggests that the first applications of its technology will be announced via partnerships with manufacturers in the coming months. The company has already established two “robust” mammalian cell lines to support its food and pharmaceutical partners.

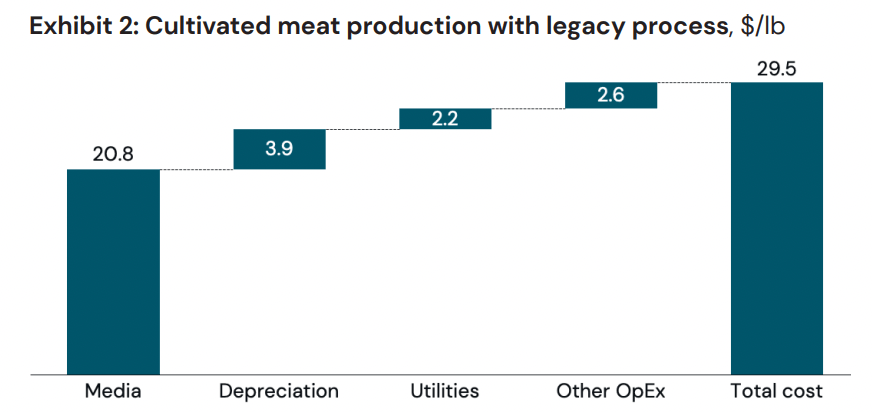

While more details on pricing will be available once these link-ups are established, Kent offers: “One of the key benefits of our photomolecular platform is cost efficiency due to our use of light, which is the cheapest possible input into biology. Our process also removes the need for costly growth factors, which are the most expensive part of the cultivated meat process.”

Reducing the cost and scaling up production are the two key manufacturing challenges facing producers in this space. While companies have managed to reduce costs by 99% in less than a decade, forecasts show these proteins won’t price parity until 2030. But startups like Meatly and BioCraft Pet Nutrition (both making cultivated pet food) have announced breakthroughs in their culture media to drastically bring down the cost of their products.

“Our platform elevates our partners’ existing cell lines and product approaches, providing a critical infrastructure layer for biology,” says Kent. “Think of us as the ‘NVIDIA for biology’. We are already co-developing the future of biology with a number of partners.”

While some countries and US states have imposed bans on cultivated meat, these proteins have been championed by UN climate bodies like the IPCC and the UNEP, since they have a much smaller environmental footprint, can secure the food system against climate and disease shocks, and feed an ever-hungrier planet poised to have 10 billion people by 2050.