4 Mins Read

Using publicly available data, non-profit and alternative protein advocacy organization the Good Food Institute (‘GFI’) has identified commonly-recognised predictions about the future of plant-based meat. A newly released report suggests that the latter could account for 6 percent of total global meat and seafood production, by 2030. In manufacturing terms, this means 25 million metric tonnes of animal-free protein will need to be produced every year. The estimate is a boon for the burgeoning plant-based meat manufacturing sector, with further scaling and innovation needed.

Breaking the figure down the numbers further, the report states that at least 810 worldwide plant-based manufacturing plants will need to be operational to meer this demand, with each one accounting for at least 300,000 metric tonnes of product a year. The report’s conclusion is clear: effective infrastructure will become essential.

Tough times ahead?

While the shift signals hope in the battle against climate change as livestock account for more than 14 percent of all emissions, GFI predicts pressure for supply chains. In particular, it cites vital ingredients such as coconut oil and pea protein as susceptible to supply difficulties. In order to relieve this burden, GFI has made a number of suggestions.

The private sector is being urged to step up. Investors, equipment suppliers, and ingredient developers are just some pinpointed as capable of taking a significant proactive stance. In addition, governments around the world are being implored to consider state-backed plant-based initiatives. China’s recent addition of cultivated meats and future foods into its five-year agricultural plan is an example of the mindset shift needed by those in power. Governments are asked to consider investing in plant-based infrastructure, to support the industry’s growth.

Pressure on supply chains is being connected to the historic outpacing of demand versus the production of plant-based meat. Limited facilities and capacity have driven prices higher, caused delays, and ultimately, stunted the growth of the industry. However, now that a shift towards less meat consumption is being cited as a valid climate change reversal tool, increasing numbers of people will be looking for sustainable alternatives.

The retail sales growth rate of plant-based meat in the U.S. was also analysed. It found that the CAGR was 18 percent. Assuming that figure stays the same, GFI used this as a baseline for calculating production requirements and infrastructure needs around the world.

Complications in the pipeline

GFI recognises that simply building enough factories is not the answer. The plant-based meat supply chain involves a number of participants, from protein crop farmers to packaging suppliers, distributors, among others. Notably, reliable ingredient supply will be essential to avoiding production bottlenecks. GFI is explicit in its recommendation that industry disruption continues. It cites a reliance on a small number of key ingredients, such as pea protein, soy and wheat gluten as restrictive, though it understands that the development of alternatives is costly and experimental. Green Queen has predicted a surge in demand for more plant-based meat varieties, which could tie into this issue.

Concluding its findings, GFI states that building out global infrastructure to rival conventional meat production is an enormous task. It reiterates that it is a sector worth investing in, however. Recommending partnerships between ingredients suppliers and product manufacturers to construct new premises together, it promotes collaborative thinking. It states that even if plant-based meat growth does not follow the predicted path, it will remain an industry driven by supply shortages, not consumer demand. This is a complication that needs to be reversed.

Building out for a bigger future

Vegan meat manufacturers are aware of the growing demand for products. As a consequence, new production facilities have been cited as motivating factors for multiple fundraising rounds in recent months.

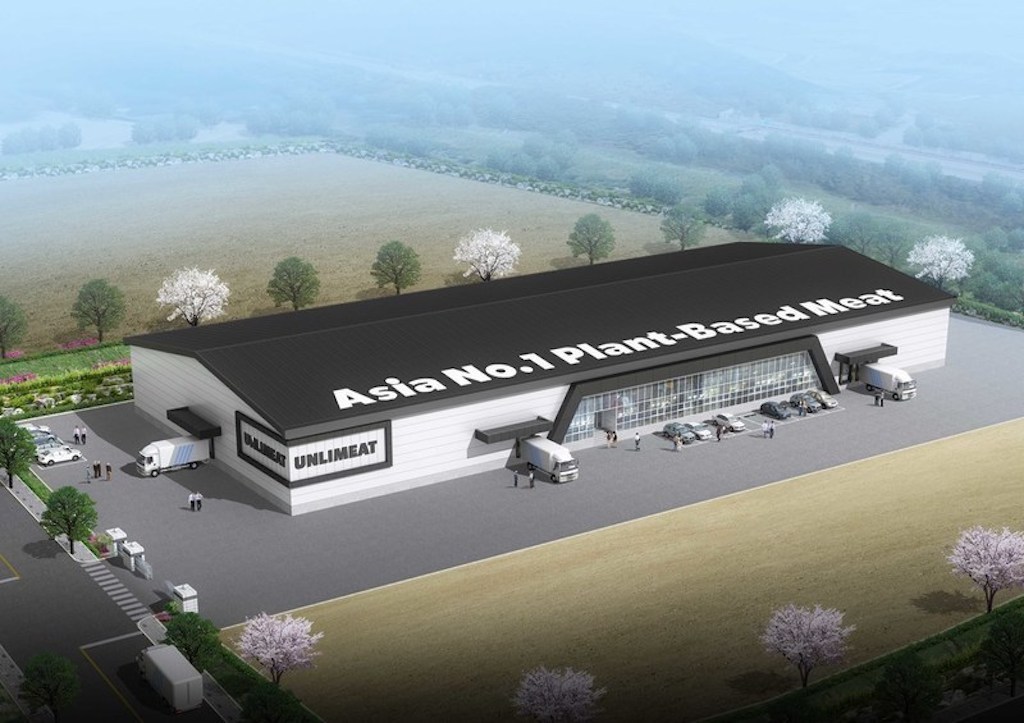

One of the most significant raises was in November last year, when South Korean Zikooin, owner of Unlimeat, raised $23 million to build one of the largest plant-meat factories in Asia. The factory will span 8,900 square metres and should be operational by summer 2022.

Sweden’s Mycorena was ahead of the curve, announcing plans for a large facility in 2021. It built a specialist production plant to increase its fungi protein supply. It is due to officially open this year.

The US’s MyForest Foods, formerly Atlast Food Co, has just announced plans to scale production of its mycelium bacon. Having scooped $40 million last year, the company is constructing a vertical farm that has the capacity to produce three million pounds of animal-free meat per year.

Lead image by Mycorena.