UK Startup Develops AI Software to Help Alt-Protein Industry Scale Up Faster & Lower Costs

4 Mins Read

London-based New Wave Biotech has launched an AI bioprocess simulation software to help alternative protein companies expand production faster and cheaper.

To address two of the biggest challenges facing alternative protein startups – higher scale and lower costs – New Wave Biotech is enlisting the help of artificial intelligence.

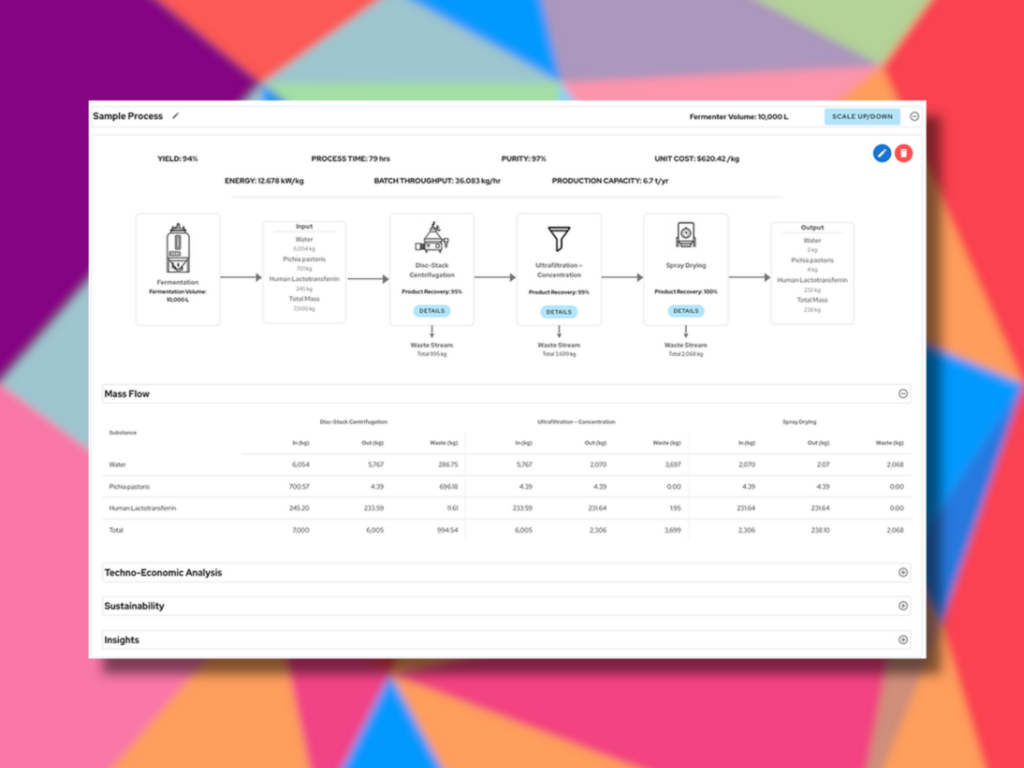

The British firm has created Bioprocess Foresight, an AI-led simulation software to help alternative protein and biomanufacturing companies design smarter and scale up more efficiently to accelerate their path to market.

The platform gives biotech innovators access to techno-economic analyses, as well as data about output and environmental impact – and this is all tailored to their individual processes.

“For too long, biomanufacturing innovators have been paying hundreds of thousands for R&D and thousands more just to understand where past experiments have failed,” said New Wav Biotech co-founder and CEO Zoe Law.

“Now imagine if you’re developing a new bioproduct and can virtually test any process to predict its techno economics and sustainability when it scales. This gives you the foresight with quantified impact that you need for strategic decision-making.”

How New Wave Biotech uses AI to help alt-protein scale-up

Analysis by the Boston Consulting Group suggests that a third of global manufacturing can be produced with synthetic biology by 2030, replacing planet-harming animal-based foods, among other unsustainable products.

However, the consulting giant warns: “Although they could be promising at the lab stage, more than 90% of synbio technologies fail because they can’t be scaled.”

According to New Wave Biotech, this is because the optimisation of these bioprocesses is hard. There are more than a trillion possible combinations of processes, with the average cost of conducting an experiment ranging from $10,000 all the way up to $100,000. Cost insights are slow and expensive too, with techno-economic analyses costing between $20,000 and $40,000 and taking months to complete.

Scaling from lab to commercial levels, meanwhile, takes anywhere from three years to a decade. With Bioprocess Foresight, the startup can simulate these processes to predict the quantified output, costs, and sustainability impact.

The software, which improves as it learns from empirical data, is capable of conducting automated techno-economic calculations in hours instead of months, and understanding companies’ projected output, economics and sustainability impact from a monthly fee of £83 ($105), versus the tens of thousands mentioned above.

Working through what New Wave Biotech describes as an “intuitive design” interface, food tech and biomanufacturing players can get a full picture of their process across commercial, technical and environmental areas, navigate trillions of interrelated options with analysis and visualisation tools, and virtually test unlimited scenarios by changing technical, market and production variables.

New Wave Biotech argues that the AI-led software can help biomanufacturers make better decisions to speed up R&D and commercialisation efforts, and allow corporates to leverage historical experimental data to power future R&D efforts. It also enables processing tech companies to accelerate sales by letting customers test their technology virtually and see the impact on their bottom line.

AI’s climate footprint is a concern

“Biomanufacturing businesses today have to navigate a landscape of thousands of potential options so need to be able to make explainable predictions of technical, commercial and environmental impact and optimise accordingly,” said Oli Hall, co-founder and CTO of New Wave Biotech.

“That’s why our bioprocess simulation platform is designed to enable biotech innovators to design better, commercialise quicker and scale greener,” he said.

New Wave Biotech has previously partnered with growth media specialist Multus to create more affordable inputs for cultivated meat producers via the latter’s AI capabilities. And last month, it received a €20,000 grant as part of the EIT Food Accelerator Network Tech Validation Award. It will use the funds to test and validate its technology with research body CPI to help clients gain confidence in its system’s predictions.

AI’s influence on the alternative protein industry is growing. Shiru has an AI-powered platform to discover proteins and ingredients, Climax Foods employs machine learning to reverse-engineer what makes cheese taste good, NotCo uses an AI platform to match thousands of plant-based ingredients and find the combinations best suited to replace animal proteins, and Singapore’s Howw Foods makes its vegan eggs with help from the tech.

But AI comes with its own problems. The data systems these large language models run on mostly use fossil fuel energy, and emit 2.5-3.7% of global emissions. One estimate predicts that data centres and communication tech are set to account for 14% of global emissions by 2040.

ChatGPT, the world’s most popular AI chatbot, has an estimated carbon footprint of 8.4 tons per year – although some say this is massively understated. And each query you make on ChatGPT generates 4.32g of carbon (nearly 22 times higher than a standard Google search).

But while AI can help curb livestock emissions by propping up alternative proteins, the tech’s own climate footprint needs to be dealt with too.