7 Mins Read

As more and more companies focus on whole-cut plant-based meats, some are relying on fat to produce highly desired marbled textures for consumers – could it be the new ‘holy grail’ for vegan steak?

Last year, scientists at Texas A&M College of Agriculture and Life Sciences explored how people eat and chew their food, with the goal of discovering what they really wanted in terms of mouthfeel. Dividing them into chewers, crunchers, smooshers and suckers, the researchers found vast differences in texture preferences among Americans.

They then dove into burgers to find out what the perfect burger for all kinds of eaters could be. Chewers didn’t want a soggy bun, crunchers resented overly dry or chewy burgers, smooshers didn’t care for any gristle, and suckers wanted a burger that’s seasoned before it’s cooked. The distinct tastes are perhaps why it was surprising that when it came to steak, there was a common aspect favoured by all eaters: marbling.

Even for different reasons – the ageing process produces big gaps among mouth behaviours – higher-marbled steaks were preferred by all respondents. And it speaks to a wider issue in the plant-based meat industry, where texture is highly sought-after. Whole cuts have long been touted as the ‘holy grail’ of meat analogues, but with a host of startups now making these products, we may need to look at what it is that makes these cuts so desirable.

Plant-based meat’s texture is important, but marbling is tough

In marbled products like steak, the fat melts into the meat as it cooks, which results in a juicy, tender mouthfeel. Keying into texture is extremely important for plant-based meat brands, given that in the US alone, texture is the aspect of vegan food consumers dislike the most. In the UK, 51% of people say taste/texture is the biggest factor driving them away from meat alternatives.

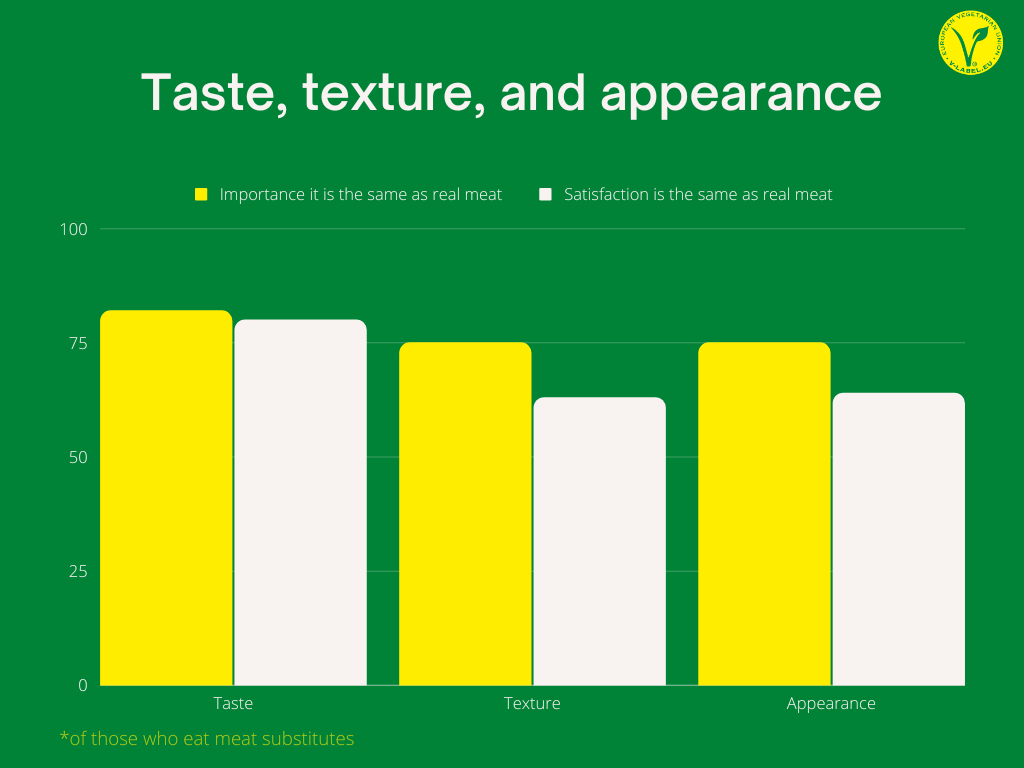

Globally, too, plant-based meat’s texture is as important as their conventional counterparts for 75% of consumers, but only about 60% are actually satisfied with the former. “Consumers want a texture and mouthfeel that’s close to meat,” Shannon Coco, strategic marketing director at Kerry, told FoodNavigator last year. “Without this, the overall experience will be disappointing.”

But creating heterogenous products like marbled meat is a complex process, with companies facing difficulties “creating solid fat differentiated from protein and with a melting temperature gradient above room temperature”, as explained by the Good Food Institute.

Juicy Marbles’ whole-cut filet mignon

So what do you do? Some are working on specific technologies to overcome this hurdle. When Slovenia’s Juicy Marbles launched its filet mignon in 2022, it grabbed headlines across the world for its trademark marbled texture, which is created with its patent-pending, 3D-assembled ‘reverse grinder’ technology.

“Our business is based around the concept of protein texture – this is the defining factor that draws people to steak, when compared to a cheaper cut,” the startup told TechCrunch in 2021. “In the plant-based meat vertical, there has not been as much innovation in the whole-cuts space, and no one has come close to inventing a steak that resembles anything high-end.”

Using a grinder it calls the Meat-O-Matic 9000, plant protein fibres are layered on top of each other to mimic animal muscle fibres, with deposits of hardened sunflower oil adding a realistic fat-marbling mouthfeel. But if you go by anecdotal evidence, for many, Juicy Marbles’ steak resembles more of a brisket, braised beef or even pulled pork – demonstrating the challenge plant-based meat producers face in satisfying consumers’ textural preferences.

Nourish Ingredients’ precision-fermented fat

So, the key is fat – which is exactly what some companies are trying to innovate with. At SXSW Sydney in October, Australian startup Nourish Ingredients unveiled a “breakthrough fat” called Tastilux, which is designed to help plant proteins deliver the same taste, smell and experience as conventional meat. The proprietary fat relies on naturally occurring lipids scaled through precision fermentation, and enables similar cooking reactions when used in plant-based chicken, beef, pork and other alternatives.

“Tastilux represents a quantum leap in making plant-based meats live up to the rich, fatty taste and cooking performance consumers want and love,” said Nourish Ingredients founder and CEO James Petrie. “We saw an opportunity to revolutionise plant proteins by focusing on the power of fat. Most alternative fats simply can’t replicate the rich, authentic flavour of cooked meat.”

He explained: “So rather than take a plant-based approach, we analysed the most flavourful animal fats in their uncooked state. Then identified where we could find these in nature, without the animal. By fermenting only the most potent fats, we’re able to recreate the authentic meat experience.”

Swiss scientist’s pea protein beef

In 2022, Swiss material scientist Martin Hoffmann developed technology to create marbled plant-based meat, using a combination of fats and pea protein to make innovative alternatives to meat dishes like steak. He processed the pea protein with biochemical engineering techniques, turning it into a plant ‘dough’ that is pushed through a proprietary attachment and combined with other ingredients like fat.

The quantity of the oil – added as an emulsion – could be tweaked to ensure flavour-comparable as well as health-forward alternatives to beef. “You have to imitate something highly irregular,” Hofmann said. “Because when we look at one half of a steak, it tells us nothing about what the other half looks like.”

At the time, he predicted the technique would be market-ready within one year, with his technology assisting B2B customers in developing more realistic meat alternatives to persuade “people to give up cheap, factory-farmed meat”. So far, though, this tech is still in the development stage.

Project Eaden’s fibre-forward tech

Meanwhile, German food tech startup Project Eaden has also been banking on its technological prowess for its vegan steak, with a novel bio-fibre tech that’s similar to fibre-spinning for synthetic fibre, which is used across textile, aviation and automotive industries, among others.

Project Eaden is using the same technology for meat – and claims it’s highly scalable and affordable. It explains that these fibres can be designed with precision to meet technical requirements like elasticity, water-binding ability and strength. The ultra-thin fibres are bundled into strands replicating conventional muscle tissues and then blended with vegetable fats for a near-identical marbled plant-based steak.

“Both plant and muscle fibres are versatile building blocks with fascinating material properties, which is why so many of today’s high-tech materials are natural fibre-inspired,” said co-founder David Schmelzeisen. “For example, we use carbon fibre for rockets and satellites, and biomaterial-based implants for humans. Now, for the first time, we’re replicating meat, fibre by fibre, using proven and easily scalable textile industry technologies.” The company planned to go to market at the end of last year, but that hasn’t happened yet.

Planeteers and Handtmann’s novel solution

Most recently, German companies Planeteers and Handtmann teamed up to provide a way for plant-based manufacturers to develop meat analogues that feature not just marbling or fat layers, but also an authentic, fine fibrous structure.

Producers can merge a newly developed attachment for Handtmann’s filling and portioning systems with system solutions from Planteneers’ fiildMeat and fiildTex series. The latter is the basis for these meat and fat alternatives to steak, filet strips and bacon, which are produced with a flexible coextrusion system.

Manufacturers can adjust the size and shape and define the fat layers of the final products based on consumer needs. And depending on the fat ratio and the machine setting, asymmetrical fat marbling is possible. Plus, with a throughput of over a ton per hour, they can churn out large quantities of steak alternatives and meet the demands of larger trade partners.

Fat is crucial for marbled vegan steak

These are just a few examples of what companies are doing to meet consumer demands for texture and mouthfeel. Swedish startup Melt&Marble is leveraging precision fermentation to make realistic animal-free fats, while California’s Yali Bio uses the same tech to engineer alternatives to animal and plant-based lipids and fats for plant-based analogues, including meat.

Similarly, San Francisco-based Lypid has created a proprietary PhytoFat for plant-based meat, and is now launching meatballs to the US market. Sweden’s Mycorena makes fermented fungi-based fat to replace animal fats, while Barcelona’s Cubiq Foods is developing omega-3 fats for alternative protein. Hong Kong-based OmniFoods makes a vegan OmniNano fat to mimic the juiciness of conventional meat, and AI-led startup Shiru‘s OleoPro plant fat is geared at alt-protein applications.

And outside vegan applications, Silicon Valley’s Mission Barns is making cultivated animal fat, Dutch startup Upstream Foods makes cell-cultured salmon fat, while Singapore’s ImpacFat makes cultivated fish fat.

There’s a lot going on in the vegan marbled steak world, but the importance of fat is growing by the day. Can somebody claim the holy grail?