Japan’s IntegriCulture Announces Five Collaborative Projects to Advance Cultivated Meat

5 Mins Read

Japanese startup IntergriCulture has announced five new projects under its CulNet Consortium, with its CEO emphasising the importance of knowledge-sharing.

If we’re to commercialise cultivated meat on a mass scale at affordable prices, collaboration is the name of the game. according to Yuki Hanyu, CEO of Japan-based cellular agriculture innovator IntegriCulture.

“The challenge with cellular agriculture is that we need to establish an entire supply chain that is also broad in nature. No single entity can do everything, and there are some supply chain components that existing corporate entities are simply better at,” he tells Green Queen.

“The industry currently needs things that do not exist in the market, and some form of R&D is required. But I think such an effort potentially benefits suppliers as they find a new place in an emerging industry,” he adds.

This is why IntegriCulture, a cellular agriculture pioneer in Japan, has announced five new projects as part of CulNet Consortium, which was first established three years ago.

To bridge the gaps in the cultivated meat sector and build an efficient supply chain, it’s organising joint research projects with five members of the consortium.

“Many of the pressing issues of the current cellular agriculture industry – such as migration from biopharma to food grade, purchase order scale, quality assurance, and IP – are addressable to [a] lack of supply chain,” explains Hanyu, suggesting that efforts like the CulNet Consortium are one of the “most effective ways of breaking this chicken-and-egg situation”.

Culture media costs and food safety key priorities

The first project deals with culture media, a mix of nutrients that facilitate the growth of animal cells. This makes up the bulk of the price for cultivated meat, costing hundreds of dollars per litre. Numerous efforts have been made to reduce this cost internationally.

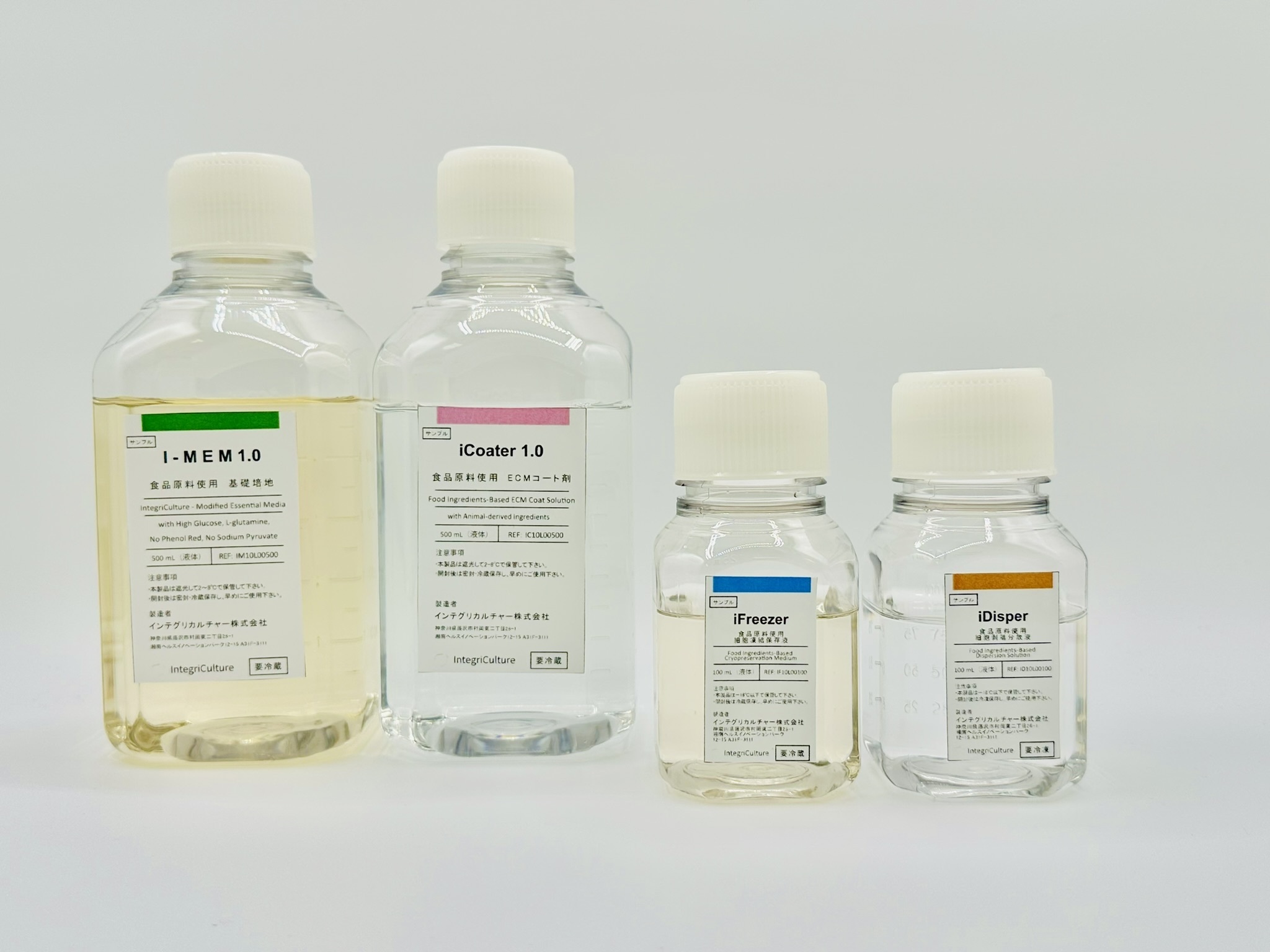

With food manufacturer TableMark (a subsidiary of tobacco, pharma and food giant JT Group), IntergriCulture is developing a basic culture medium “made from food ingredients that minimises the use of highly processed materials”, and cuts the number of raw materials in half (from 31 to 16).

In the second project – with ingredient specialist San-ei-gen FFI – it is building a novel scaffold for 3D cultivation. “Our scaffold is made from food-grade ingredients, and various types of cells can grow on it with higher density than previously known,” sais San-ei-gen FFI. The effort aims to uncover scaffold performance and optimisation of the cultivation condition.

The third project also focuses on culture media, with life sciences company Nacalai Tesque joining forces with IntegriCulture to develop cost-effective media with safe, reliable raw materials that have already been used in food products.

The next project is with chemicals and pharma behemoth UBE Group. Stable production of cultivated meat necessitates the long-term supply of growth factors produced by organ cells. “We have focused on the improvement of supply stability of growth factors by [the] creation of a comfortable environment for cells,” said UBE Group.

Finally, one key challenge of cultivated meat production is the prevention of bacterial contamination when the cells are being cultured. But traditional methods aren’t applicable for food products in Japan. So IntegriCulture is working with an anonymous member company to create antibacterial tech using food-grade ingredients.

IntegriCulture brought together these industry players back in 2021 to “build a whole cellular agriculture supply chain”, and these new projects advance this goal. The 14-member CulNet Consortium began with five targets: creating standardised culture media for different cultivated foods, streamlining processing and quality assurance protocols, certifying safety-tested cells and cell licensing schemes, building the required hardware, and developing bioreactors.

Cultivated meat in a ‘trough of disillusionment’

The end goal of all these projects is to develop products that will be sold on Ocatté Base, IntegriCulture’s B2B marketplace, to proliferate players in the cellular agriculture space. “This would ultimately lead to democratisation of cellular agriculture,” argues Hanyu.

The company has already been selling cosmetic ingredients made from cellular agriculture. “We are currently a supplier of cell-ag related hardware and services, and becoming an infrastructure provider,” he says. “We are also planning to launch a cell-cultured food demonstration product.”

IntergriCulture was the recipient of a ¥1.87B ($13.1M) grant from the Japan government last year to advance the CulNet infrastructure platform and make its developments open-source. It has raised $16.4M in equity funding, and has also been working with the Japan Aerospace Exploration Agency and the Tokyo Women’s Medical University on a project involving cellular agriculture and cultivated meat production in space.

Japan, in fact, had a shake-up in its regulatory process earlier this year, with the Ministry of Health, Labour and Welfare transferring its food hygiene standards division to the Consumer Affairs Agency, while continuing to oversee food safety.

It means companies must liaise with two agencies on regulatory conversations, but makes prime minister Fumio Kishida the ultimate authority on these matters. But it’s still too early to tell what the consequences of these shifts in the framework – which is still being developed – will be, according to Hanyu.

That said, he believes the cellular agriculture industry is going through a “trough of disillusionment”, which usually follows a hype cycle. Investments in this space fell off a cliff in 2023, down by 75% from the year before. Some startups have had to lay off staff, or cease operations altogether.

If you overcome the disillusionment stage, though, you’re set for steady growth and disruption. “To get out of there, the industry must make and sell things, but the industry seems to fall short on both,” says Hanyu.

But he remains positive: “I’m optimistic about the unique value cell-cultured products can provide, especially if we look beyond food or commonly discussed social values that are often politicised.”