3 Mins Read

Hong Kong-based startup Hydroplast is fighting the plastic pollution plaguing oceans around the world through its new ground-breaking water-soluble technology. Plastic waste is especially prevalent in convenient-obsessed Hong Kong and other cities where excessive packaging is commonly used in supermarkets and stores and ends up in surrounding seas and already overflowing landfills.

Green Queen Editorial Disclaimer: Hydroplast products are made from PVA, aka polyvinyl alcohol. While the water-soluble material can be certified compostable according to the US Standard ASTM D6400 and the European Standard EN13432 and doesn’t contain PP, PE, PS and PVC plastic, PVA is a synthetic polymer derived from fossil fuels.

Our instant gratification culture, which espouses the use of disposable plastics, have had a detrimental impact on our environment. These non-biodegradable products, such as unnecessary cling film packaging wraps, plastic water bottles, micro-beads in cosmetic products and single-use cutlery, have not only inundated landfills but have also polluted our waters. Improperly littered plastic products that end up in oceans and rivers, over time, get eroded into micro-plastic – tiny plastic particles that are harmful to aquatic life and end up back into our food chain through seafood and water consumption. The most recent research has found that this is a problem that is truly global – from Hong Kong and Singapore to Europe and North America, plastic is everywhere.

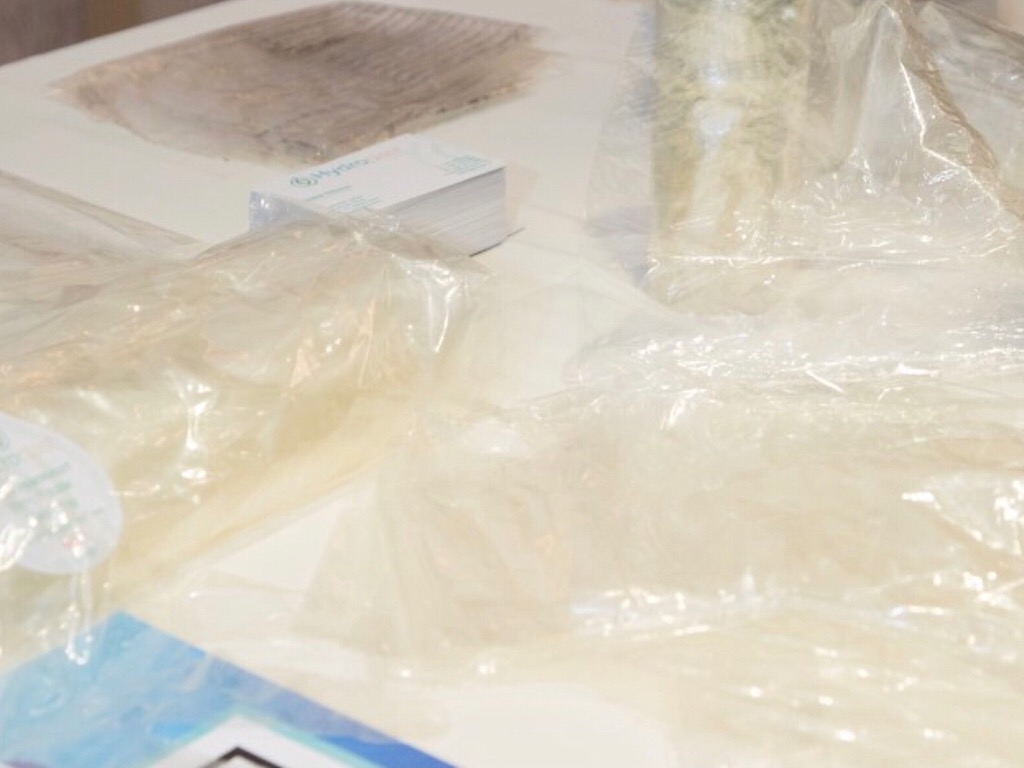

Started with a mission to protect the planet from single-use plastic, Hydroplast developed a unique smart water soluble polymer. Products made using this patented technology are biodegradable, compostable and non-toxic. The company hopes that it can replace single-use plastic products over time to minimise the damage we have already caused to marine life and the environment.

This technology can be applied to replace everyday items that would typically be made with soft flexible plastic film, such as plastic carrier bags, cling wrap, tape, gloves and retail packaging. Hydroplast films can even be printed on in the same way as conventional plastics, but the company has taken the extra step to only use ink made from organic ingredients to ensure that no toxins are left behind when the product is dissolved. Once dissolved in water, what is left is only hydrogen, carbon and oxygen – making it as safe as drinking water, according to the company’s founder.

Most recently, the start-up celebrated a new partnership with social impact upcycled fashion brand The R Collective. The collaboration will see the brand, which uses waste materials from Hong Kong charity Redress, package their products using Hydroplast. This new 100% non-toxic packaging bag will naturally biodegrade within 360 days when disposed normally or it can be instantly dissolved in hot water.

The innovative plastic-alternative company is special because it retains the convenience aspect of traditional plastic products that many consumers hold dear. While the water soluble polymer has been in use for years in surgical stitches and laundry tablets, it has never been developed for commercial application in the way Hydroplast envisions. The company hopes that as the demand for alternatives to single-use plastic grows, they can start manufacturing a bio-based version of Hydroplast for widespread commercial use.

Lead image courtesy of Hydroplast.