3 Mins Read

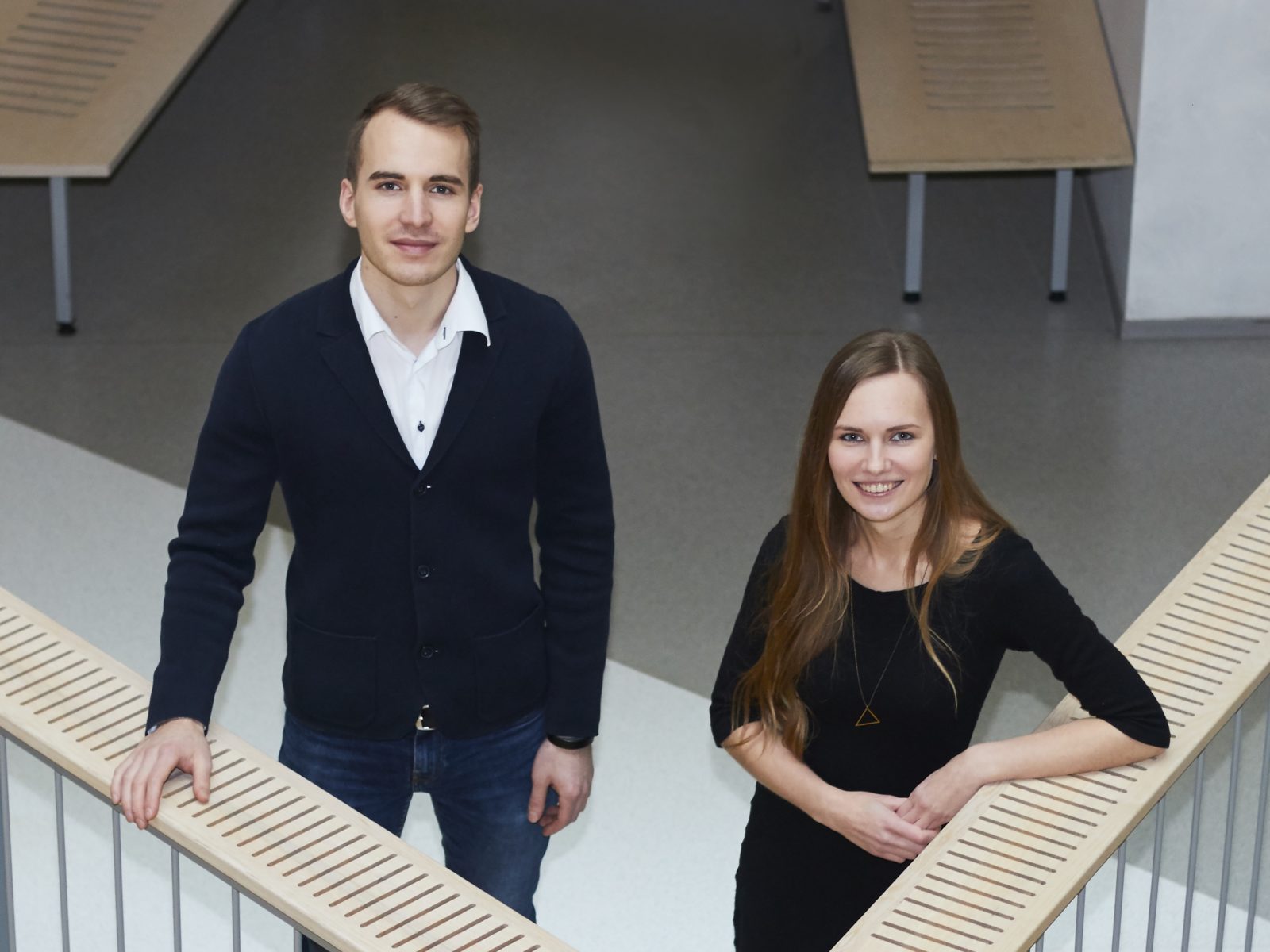

Estonian startup Gelatex Technologies has secured €1.2 million in seed funding. The investment will be used to continue the development of plant-based polymer scaffolds. Up to 90 percent cheaper than alternatives, the scaffolding could allow cultivated meat to be rolled out and cost-effective. New premises are being constructed to increase production, ahead of predicted demand.

The €1.2 million seed round was led by Change Ventures and Crosslight Partners. Previous funding sources included US accelerator Techstars. The development of affordable scaffolding is key to creating cultivated meat products that are affordable to consumers. It is also an important textural element.

The support of scaffolding

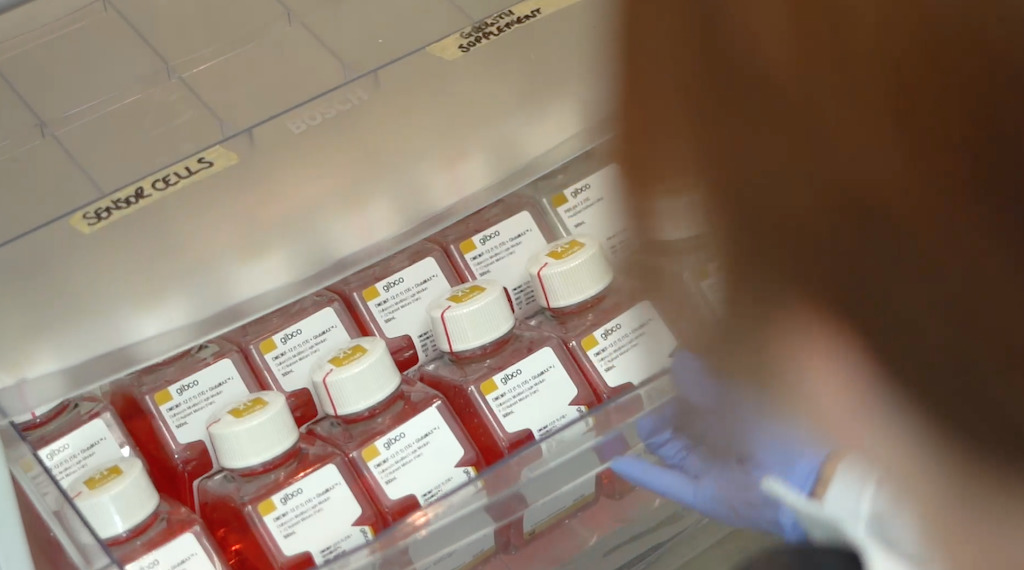

As the name suggests, scaffolding is a supportive structure. In the case of cultivated meat, it gives products body, textural diversity, and strength. Without it, finished items would not resemble conventional meat. Traditionally, scaffolding has been constructed from electrospun and hydrogel liquids but these have proven financially unsustainable. Gelatex uses biopolymers to make a nanofibrous multifaceted scaffolding structure. Fibre size and porosity can be adapted to better suit specific meat types, to enhance replication of conventional products.

Estimated at €100,000 per kilogram, scaffolding has been a hurdle to bringing cultivated meat to market. Gelatex claims that its plant-based polymers cost just €1,000 per kilogram. Costs could reduce further still.

“If we stay true to our ambitions and keep scaling our technology, it will cost only €40 in less than five years and €20 in less than ten years. This is less than €1 of scaffold per kg of meat,” Gelatex CEO Märt-Erik Martens told FoodIngredientsFirst.

Scaling up

Testing is ongoing with eight of the 10 leading cultivated meat manufacturers trialling the technology. So far, the product has lived up to its claims and garnered good results worldwide. Gelatex revealed that its scaffolding has been designed to work seamlessly with beef, pork, and chicken. It can also be used with fish and seafood cells.

Positive testing feedback and significant cost-savings for users has led Gelatax to begin construction of a new production unit. Designed to manufacture three times as much as current machinery, it will be used as a template for scaling up wherever needed. “It’s about multiplying the industrial machinery to deliver the quantities needed,” Martens said.

Looking for price parity

The cultivated meat industry is consistently looking to reduce prices for end consumers, given that cost is one of the major obstacles ahead. At present, it is estimated that it costs $50 per pound for a finished piece of meat. Bringing it in line with the equivalent conventional meat is a top priority.

Belgium-headquartered Tiamat sciences is looking to contribute to the price parity mission. Using plant molecular farming, the company is making alternative growth factors. Current options cost £2 million per gram to manufacture. By 2025, Tiamat aims to reduce this by 1,000 times.

Elsewhere in the industry, Dutch beef manufacturer Mosa Meat has reduced the associated costs of its fat medium by 66 times. Earlier this year, it secured a €2 million EU grant to keep driving costs down. South Africa’s Mzansi Meat Co., meanwhile, claims it will achieve conventional meat price parity within 10 years.

Lead image courtesy of Gelatex.