Israeli Startup Announces ‘Record-Breaking’ Development to Make Cultivated Seafood Affordable

4 Mins Read

Rehovot-based Forsea Foods has recorded the highest level of cell density in the cultivated meat and seafood industry, helping it achieve costs lower than conventional eel meat.

As it prepares to launch cultivated unagi in Japan in 2026, Forsea Foods has achieved a critical breakthrough in its production process.

The Israeli company’s technology has reached a cell density of over 300 million cells per ml with minimal and precise use of cultured media, which make up the bulk of the costs of cultivated meat. This, the firm says, will allow it to further reduce costs of its planet-friendly version of freshwater eel meat.

Cell density can greatly affect the viability of cells, and how they proliferate and differentiate. Cultivated meat involves growing cells at high densities, which can often dictate when companies harvest the cells after cultivation. For some, developing technologies to produce these proteins at high densities in smaller spaces is key to their market path. Forsea Foods says its breakthrough means it now has the highest cell density in the industry.

How Forsea Foods created cultivated eel meat

Forsea Foods is tackling a $4.3B luxury market for eel meat, which commands wholesale prices between $40 and $60 per kg in Japan, the consumer of over 70% of all eel caught globally. The fact that freshwater eel is a critically endangered species that’s hard to breed in captivity makes it a delicacy in the country.

Poaching, illegal trading, breeding troubles and pollution have decimated supplies of the fish, with consumption declining by 63% between 2000 and 2021 in Japan. Overfishing, meanwhile, doesn’t just disrupt eel populations, but also the marine and freshwater ecosystems they inhabit.

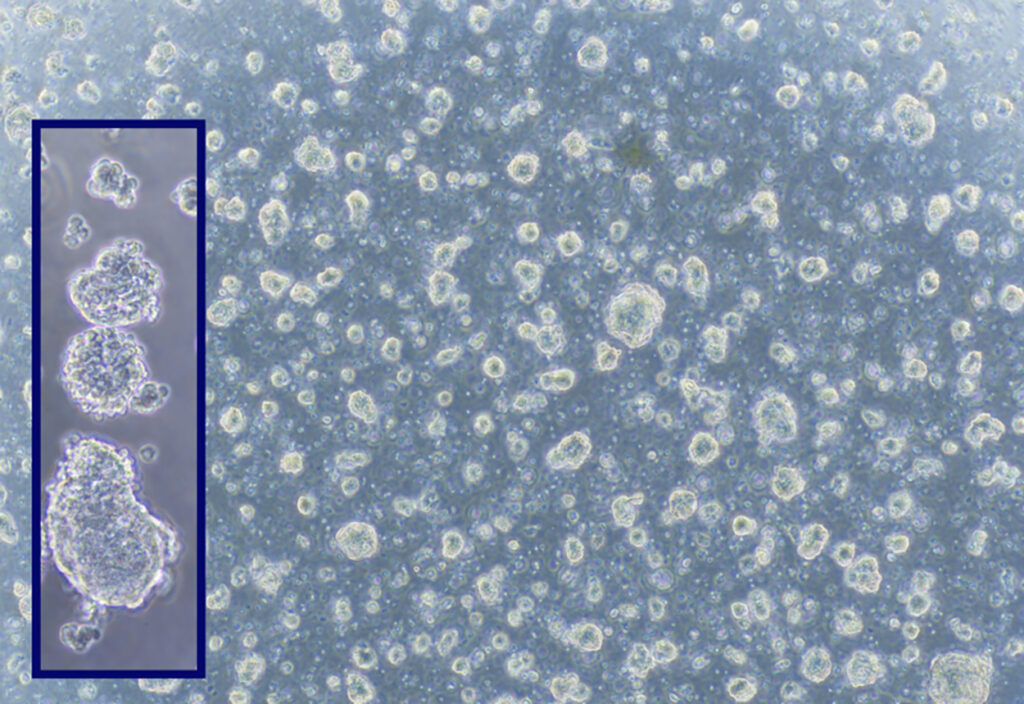

The three-year-old startup first showcased its cultivated eel at Saido, a vegan restaurant in Tokyo. The product is grown via Forsea Foods’s proprietary organoid technology, which involves creating the ideal environment for cells to assemble into 3D microtissue structures comprising fat, muscle and connective tissues.

These mimic organ functions and structures, and spontaneously differentiate into edible cells, replacing the natural growth process of tissues in a living animal. The process also bypasses the scaffolding stage (where cells are grown on 3D scaffolds to create structured proteins) and significantly lowers reliance on growth factors, helping it produce cultivated meat in a cost-effective manner.

“The breakthrough to this level of cell density highlights the strength of our organoid technology,” said Forsea Foods co-founder and CTO Moria Shimoni. “It’s a validation of our approach to high-efficiency cultivation of seafood to meet both economic and sustainability goals at scale.”

Roee Nir, the startup’s co-founder and CEO, added: “This is a major milestone for Forsea and validates our vision of making sustainable, high-quality seafood affordable and widely accessible. It also sets a powerful precedent for scaling other cultured seafood products and establishing sustainable alternative supply chains for ecologically sensitive species.”

Preparing for launch in attractive Japanese market

While cultivated seafood is years away from price parity with conventional eel, the high cell density positions Forsea Foods at the forefront of efforts to lower the production costs of these novel proteins. “Forsea’s organoid technology requires less capital expenditure than other technologies,” explained Nir.

“Achieving this level of cell density with minimal resources will translate to substantial reductions in the unit of economics and will bring cultured seafood production to a cost that is actually below the traditional market price,” he added.

It has completed a proof-of-concept for its continuous harvesting process, and is now aiming to take production to the next phase of commercial scale-up. The company, which is working on six different cell lines, has raised $5.2M in seed financing so far, and intends to launch a Series A funding round soon, which will fund the construction of a commercial pilot plant.

Forsea Foods held a tasting event in Tel Aviv-based restaurant A in June, which convened investors, journalists, food manufacturers, opinion leaders, as well as government representatives. It is now preparing to file regulatory dossiers in Japan, targeting a commercial launch for 2026.

Japan is becoming an increasingly hot destination for alternative protein companies, and has a population where over two in five are willing to try these cultivated meat and seafood products, especially if they’re priced the same or cheaper.

“Officials are making steady progress in developing a novel food regulatory framework. Unlike countries that conduct individual consultations, Japanese officials primarily communicate with industry associations that speak on behalf of alternative protein companies, which fosters better market readiness for the sector as a whole,” Kimiko Hong-Mitsui, interim director of alternative protein think tank the Good Food Institute (GFI) Japan told Green Queen last month.

“Our recent industry survey shows that cultivated meat production is definitely not a one-size-fits-all approach,” Elliot Swartz, principal cultivated meat scientist at GFI, remarked on Forsea Foods’s development. “It’s encouraging to see positive data from companies showing how different methods can address challenges in cost and scale.”