Formo Stretches Budget with $61M Series B, Rolls Out Animal-Free Koji Cheese in Supermarkets

7 Mins Read

German food tech startup Formo has closed a $61M Series B fundraise and launched animal-free cheeses made from microbial fermentation in supermarkets.

If you’re in Germany or Austria, you can now walk to one of 2,000+ Rewe, Billa and Metro stores and buy a first-of-its-kind vegan cheese made from mould.

Berlin-based startup Formo, known for its exploits in fermentation, has debuted its first products on the market. Frischhain, a cream cheese analogue made from koji protein, is now available in the aforementioned grocery stores in plain and herb flavours. A tomato version is to follow in the coming weeks, alongside Camembritz (a Camembert replica).

The launch coincides with the closing of Formo’s Series B funding round, in which it bagged $61M from investors including existing backers FoodLabs, EQT Ventures, Lowercarbon Capital, and welcomed new financiers in The Nature Conservancy and Rewe Group, among a host of others.

The third-largest alternative protein investment round of this year, it takes Formo’s total raised to $117M, and will enable the startup to scale up production, expand its operations internationally, diversify its product portfolio, and push for net profitability.

The company continues to advance its precision fermentation technology platform for animal-free casein, with an eye to launching cheeses made with the protein in the first half of 2025. Next year will also see Formo introduce two more cheeses from its koji protein lineup: Frankoforte and Hellasdorf.

“Frankoforte is a rich, bold blue cheese made from koji protein, offering an intense flavour punch while maintaining a beautifully smooth, creamy texture. Hellasdorf, inspired by classic Greek feta, delivers a tangy, savoury flavour with a perfect crumbly texture,” Christian Poppe, Formo’s public affairs and sustainability director, tells Green Queen.

How Formo makes its koji protein cheese

To make its cheese, Formo uses a microbe called Aspergillus oryzae, a type of koji mould. This is a filamentous fungus that has been used for centuries in Japan, forming the base for fermented foods and beverages like miso, mirin, shoyu and sake. “Koji protein resembles whey protein, making it the perfect foundation for our cheese alternatives,” says Sandra Wilde, VP of Food at Formo.

The startup’s process mirrors traditional brewing techniques. It starts by cultivating the koji mould in steel tanks, where the microbes grow in a “nutrient-rich bath” containing sugars and micronutrients, as well as wheat flour or other carbohydrates.

As the fungi consume these nutrients, they produce protein. Once the fermentation is complete, Formo separates the biomass from the liquid (which contains the protein). This is then dehydrated using spray dryers to create a fine protein powder, which becomes the foundation of the company’s cheese products.

Once the powder has been extracted, Formo collaborates with family-owned traditional cheesemaking businesses, who use its recipe to create the end product. “These experts apply – just as we do in our pilot plant – conventional cheesemaking techniques, which include coagulation, curdling, draining, pressing, and ageing,” explains Poppe.

Partnering with traditional artisans allows Formo to “replicate the familiar taste, texture, and mouthfeel of cheese while leveraging centuries-old cheesemaking expertise”, while providing an alternative source of income for producers in a carbon-heavy industry.

The koi protein makes up 6.7% of the Frischhain cheese – the rest is made up of shea fat, sunflower oil, soluble corn fibre, salt, sugar, carrageenan, lecithins, and ripening cultures (plus flavourings for the other variants).

So while the combination of koji and time-honoured cheesemaking ensures that Formo’s cheeses deliver on taste, how does it fare on the nutrition front? The plain Frischhain has more fat (27.6g per 100g) than the Philadelphia Original cream cheese (21g), but the koji cheese has much lower saturated fat (10.1g vs 14g) and is higher in protein (6.1g vs 5.4g).

It even outperforms plant-based cream cheese on the latter two metrics. Simply V’s almond-based spreadable cream cheese, for example, has 13g of saturated fat per 100g, and 4.8g of protein.

Formo targets late-2025 launch for precision-fermented cheese

The potential of fermentation extends to sustainability as well. Formo says it’s using production partners and contract manufacturers that “fulfil the highest environmental standards”. According to an ISO-compliant life-cycle assessment (LCA) conducted by CarbonCloud, Frischhain production generates 65% fewer emissions, uses 83% less land, and consumes 96% less water than conventional cream cheese.

To go a step further, Formo is also donating any surplus food to organisations like the Red Cross or through food waste platforms like Too Good To Go. Additionally, its packaging is fully recyclable and is said to follow “eco-design principles”.

The company is currently capable of producing “triple-digit tonnes” of its cheese each month, but plans to triple its capacity in the coming year.

“Our current focus for the Micro Fermentation product line is on Europe, particularly the DACH region (Germany, Austria, and Switzerland), where we aim to establish a strong presence first,” reveals Poppe. Frischhain has already been available for foodservice consumers at Metro since August, with each 1.5kg container priced at €25.99.

He says the microbial fermentation products being launched now complement its ongoing precision fermentation efforts, allowing the business to build consumer relationships and brand recognition.

“Our precision fermentation operations are going great, and we’re making significant strides with our second-generation cheese product line,” he says. “The technology is advancing rapidly, and we’re excited about the potential of creating bioidentical dairy proteins.”

While declining to share specific launch dates, Poppe says the precision-fermented products – which include hard cheeses made with bioidentical casein – will be initially targeted towards the US, with a rollout around late 2025.

“Everything is coming together – the launch of our first products, the positive results of our environmental analyses, and the successful funding round,” says Formo co-founder and CEO Raffael Wohlgensinger. “This is the result of five years of intensive research and product development, as well as the work of an incredibly passionate team. Game on.”

Investors bet on fermentation amid alternative protein struggles

Sandra Malmber, a partner at EQT Ventures, raises an important point. “Few European companies are raising such large rounds within climate tech,” she says. “A key success factor was proving commercial traction, which is a rarity for this type of company at this point in its lifetime.”

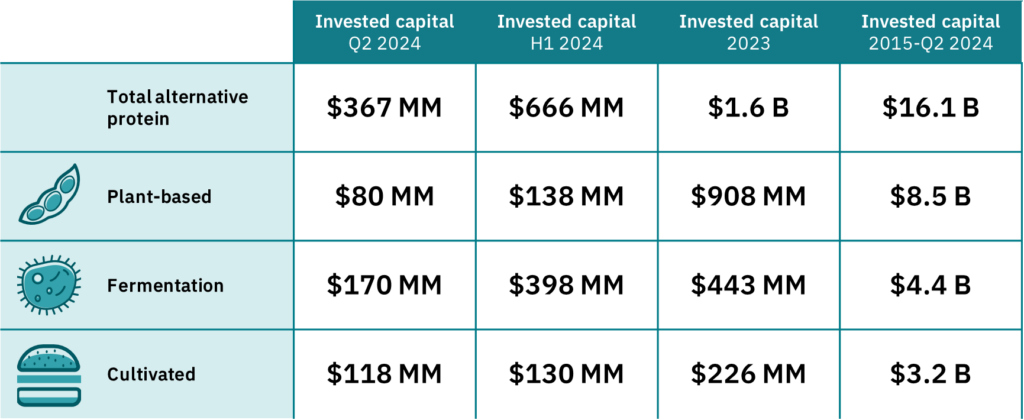

Alternative protein investments have slowed down. They fell by 44% in 2023, and while the decline appears to be halting this year, the amount of capital put into this sector is a far cry from the highs of 2021.

Amid this macroeconomic environment, Formo credits its $61M round to technological advancements it has made in the last 18 months, allowing it to come to market at competitive prices with “strong profitable product margins”.

“While our technology was already advanced, the real leap was how quickly we were able to scale it and build robust operations,” notes Poppe. “We moved from lab-scale development to large-scale production at an impressive speed, proving not only the strength of our technology but also our ability to establish strong commercial capabilities.”

Another factor that may have attracted investors was that Formo deals with fermentation. Alternative protein startups working in this space have received around twice as much funding as plant-based or cultivated meat players this year. In the first half of 2024, the fermentation segment has already obtained 90% of the money it did in all of 2023.

So perhaps it’s no surprise that the top four funding rounds in alternative proteins this year belong to fermentation companies – Meati leads with its $100M Series C, followed by Perfect Day‘s $90M pre-Series E, Formo’s $61M Series B, and Infinite Roots‘ $58M Series B.

“What makes fermentation especially exciting is that it builds on ancient food manufacturing techniques – like those used to make cheese, beer, and bread. Because it’s not entirely new to consumers, it holds great promise for rapid consumer acceptance and uptake,” suggests Poppe.

“Additionally, fermentation is easier to scale compared to other alternative protein technologies, helping us move faster toward price parity with conventional animal products, which is a major driver of investor confidence,” he adds.

Poppe believes investment levels will rise again as companies “prove their ability to scale, reach price parity, and win over consumers”.

“Fermentation is already leading the way, and as more companies hit these key milestones, the entire industry will gain momentum,” he says. “The future is incredibly bright – we’re combining cutting-edge science with tried-and-true methods to transform the food system and make sustainable, affordable alternatives widely accessible.”