Innovation Clusters, Investment & Shared Hubs Key to Netherlands’ Alt-Protein Transition

4 Mins Read

The Dutch alternative protein ecosystem is faced with a host of challenges, but increased investment and policy support can propel a climate-friendly food system.

The Netherlands recently became the first EU country to allow (and host) public tastings for cultivated meat, a marker of the government’s forward-thinking approach to the food system.

However, many challenges remain for a true acceleration of alternative proteins, which are set to represent a €10B market in the country by 2030. This will be fuelled by declining production costs technological advancements, and evolving consumer needs.

So while the sector is well-positioned to capitalise on this opportunity, it first needs to overcome the many obstacles preventing startups in this industry from scaling up, according to a new report by local firms Foodvalley NL and Invest-NL.

“The report highlights the critical need to address the scaling challenges of startups and scaleups,” said Emmanuel Anom, lead of shared facilities at Foodvalley NL. “By strategically investing in shared facilities and implementing supportive financial mechanisms, we can position the Netherlands as a world leader in the transition to sustainable protein production.”

Tackling the four main scale-up challenges

The report outlines four key barriers for companies looking to move from lab-scale to commercial production. The first concerns limited access to facilities, with demonstration- and pilot-scale infrastructure currently inefficient to meet demand. This hampers startups’ ability to test and optimise their processes, and delays their route to market.

The high operational costs of pilot facilities are another major hurdle. This involves the prices of equipment, raw materials as well as personnel, and poses a significant financial burden on startups looking to scale up in an increasingly tough funding environment.

Companies also have to deal with regulatory complexities. As part of the EU, the Netherlands follows the bloc’s stringent novel foods regulation. But the complicated, time-consuming and expensive application process here has proved to be a huge bottleneck for alternative protein companies. While regulators in the US and Asia have approved the sale of cultivated meat and precision-fermented proteins, no such clearance has been granted in the EU.

Finally, there’s a big funding gap between the R&D and commercialisation phases, something the report’s authors term the ‘Valley of Death’. This lack of investment can hold back innovation and prevent technologies from reaching the market.

The importance of shared facilities

Shared facilities can be crucial to commercial growth, helping startups access essential infrastructure and expertise. But the current manufacturing landscape in the Netherlands is fragmented.

The present capacity of shared facilities is limited and insufficient to meet the growing demand from companies across the three alternative protein pillars: plant-based, fermentation and cell cultivation.

Many of these shared hubs also lack the specialised equipment and expertise required for the production of specific proteins. This limits their efficacy in supporting a diverse set of companies.

Additionally, these facilities suffer from high operational costs, scheduling conflicts and limited flexibility, hindering companies’ ability to use them efficiently.

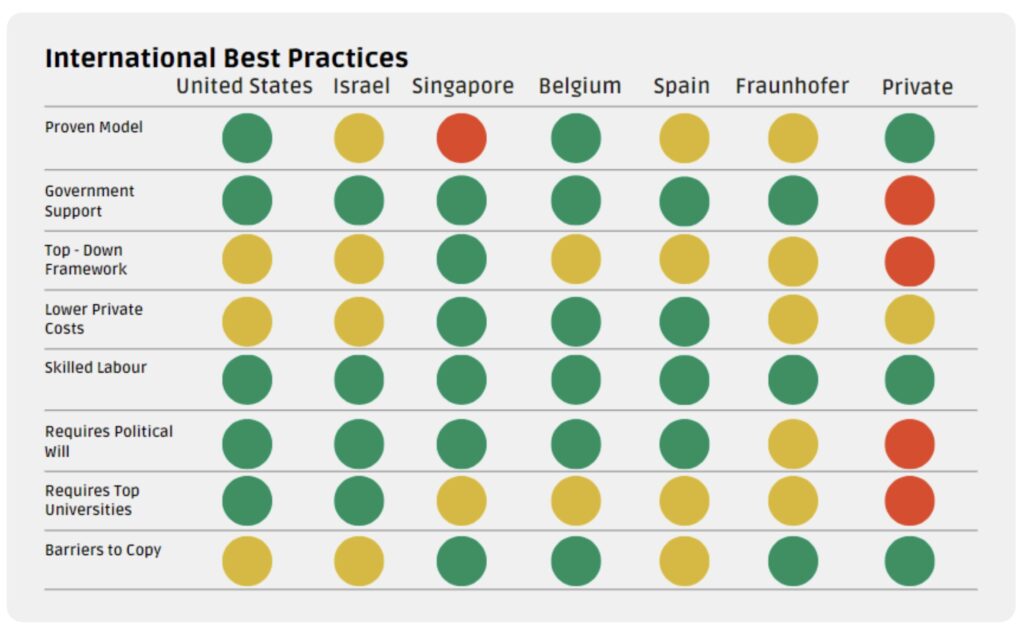

As a solution, it may be wise to look towards best practices on an international scale, including in countries like the US, Israel, Germany and Singapore. These models focus on flexibility, cost-consciousness, strong leadership, robust networks and government support as their main drivers of success.

Learning from these practices could help the Netherlands develop a more effective and supportive ecosystem to scale up alternative protein production, according to the authors.

How the Netherlands can support alt-protein scale-up

The report lists three recommendations to overcome these scalability challenges. It suggests developing a national collaboration strategy, which would involve creating innovation clusters to facilitate interaction among startups, research institutions and corporate partners.

Government policies must support these alliances with structural investments and infrastructure. Additionally, the authors call for streamlined regulations and policy incentives (like tax breaks) to aid the industry’s growth.

The report also recommends establishing regional hubs with state-of-the-art shared facilities across the country, backed by public-private partnerships. Investing in specialised equipment and expert personnel is crucial to cater to different protein production processes, and implementing flexible access models is key to making such hubs more affordable for startups.

Finally, there needs to be greater financial support in the form of voucher systems, operational subsidies and innovative funding models (like co-investment funds) to ease the burden on companies.

It will also be necessary to introduce bridge-funding schemes to aid the shift from R&D to commercialisation and ensure that policies provide financial incentives to the sector.

“To achieve a sustainable and climate-neutral food system, transitioning to alternative protein sources with lower emissions is crucial. The Netherlands has a unique opportunity to become a global leader in the alternative protein revolution,” said Michiel Strijland, business development manager at Invest-NL. “This report serves as a call to action for all parties to work together and stimulate the growth of this promising sector.”