4 Mins Read

Researchers in Japan say they’ve reached a “breakthrough” in tissue engineering that could open up “transformative opportunities” for cultivated meat production.

To solve one of cultivated meat’s biggest challenges, scientists have resorted to the circulatory system.

The same way blood vessels carry nutrients and oxygen to cells to help animals grow, scientists from the University of Tokyo have devised a “breakthrough” method to deliver these nutrients to artificial tissue, making it possible to grow whole cuts of cultivated meat, the holy grail for the future food industry.

Currently, most production methods can only render tiny pieces of cultivated meat (akin to mince), which are then assembled into a larger product via edible scaffolds, or combined with plant-based binders and ingredients to form a whole piece.

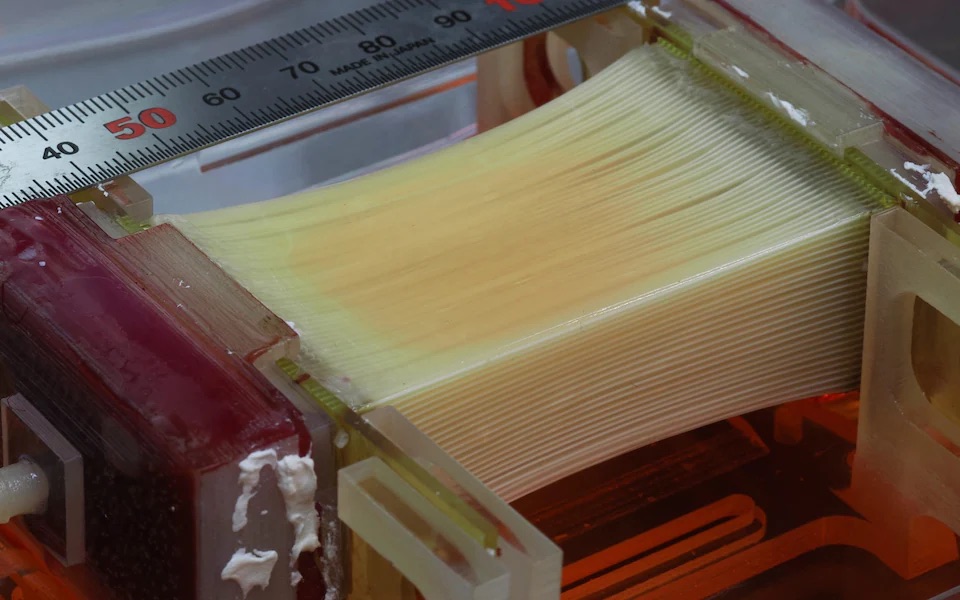

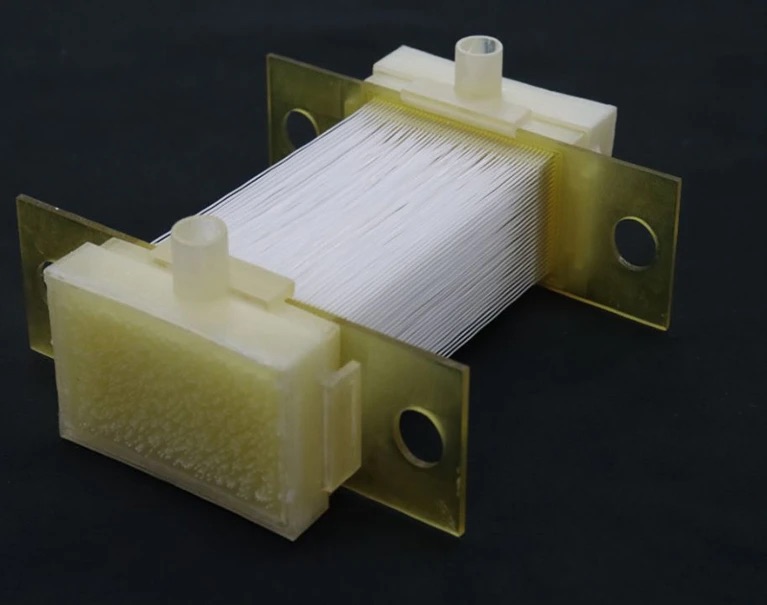

The problem lies in the random distribution of hollow fibres, which prevents uniform nutrient delivery and hinders tissue quality. Shoji Takeuchi and his colleagues have come up with what they say is a “scalable, top-down strategy” for producing whole cuts of cultivated meat using a perfusable hollow fibre bioreactor.

Could this be the future of cultivated meat?

The study, published in the Trends in Biotechnology journal, explained that getting enough oxygen and nutrients to the cells in the centre of thick tissues is a major hurdle. Diffusion alone can’t sustain cells across considerable distances.

To overcome that, the researchers developed a bioreactor equipped with an array of semi-permeable hollow fibres that function as artificial circulation systems, which ensured uniform nutrient distribution throughout the tissue.

“We’re using semipermeable hollow fibres, which mimic blood vessels in their ability to deliver nutrients to the tissues,” said Takeuchi.

“These fibres are already commonly used in household water filters and dialysis machines for patients with kidney disease. It’s exciting to discover that these tiny fibres can also effectively help create artificial tissues and, possibly, whole organs in the future,” he added.

“We overcame the challenge of achieving perfusion across thick tissues by arranging hollow fibres with microscale precision,” Takeuchi says.

Tissues without an integrated circular system have generally been limited to a thickness of less than 1mm, but this new method allowed the scientists to produce a 2cm thick piece of chicken muscle that was several centimetres long and wide. Made using chicken fibroblast cells, which make up connective tisuse, the meat weighed 11g, and was about the size of a chicken nugget.

Further, the hollow fibre bioreactor had microfabricated anchors to promote cell alignment. And when using active perfusion, the chicken muscle tissue showcased higher protein expression and improved taste and texture.

Many obstacles to overcome

“Cultured meat offers a sustainable, ethical alternative to conventional meat,” said Takeuchi. “However, replicating the texture and taste of whole-cut meat remains difficult. Our technology enables the production of structured meat with improved texture and flavour, potentially accelerating its commercial viability.”

Speaking of which, there’s still a lot to do and a long way to go before this production method can scale up and make cultivated meat fit for our plates.

There are several reasons why. The hollow fibres are not edible and must be pulled from the meat by hand, so the team is working on automating their removal or replacing them with edible cellulose fibres that can be left in and fine-tune the texture of the meat.

In terms of scaling up, as the tissue size increases, ensuring a sufficient oxygen supply becomes more challenging. So future versions of the bioreactor may need artificial blood to help carry more oxygen to cells and grow larger pieces of cultivated meat.

The researchers used cells cultured in a medium containing animal serum too, which is expensive and raises ethical concerns. To commercialise the product, the team would likely need to use plant-derived collagen and serum-free culture media, something many companies are already doing.

“Alongside solving these technological issues, regulatory challenges must also be addressed, including the approval of materials and processes for food production by relevant authorities, such as the FDA or European Food Safety Authority,” the study noted. “In addition, fostering a culture that embraces new foods is essential for the acceptance of cultured meat products by the public.”

Speaking to the Guardian, Takeuchi said with enough funding, products made using this approach could be available in five to 10 years. “At first, it will likely be more expensive than conventional chicken, mainly due to material and production costs,” he said. “However, we are actively developing food-grade, scalable systems, and if successful, we expect the cost to decrease substantially over time.”