Cultivated Biosciences Raises $5M to Bring Yeast-Derived Cream to Your Kitchen

5 Mins Read

Swiss startup Cultivated Biosciences has secured $5M in seed funding to scale up the development of its yeast-derived fermented cream, in preparation for a 2025 launch in the US.

The financing round – which brings total funding to $6.5M – was led by Dutch VC firm Navus Ventures, with participation from existing investors Founderful, HackCapital and plant-based meat brand Planted founder Lukas Böni, as well as new investors including Joyful VC, Mandi Ventures, and Zürc.

Cultivated Biosciences wants to use the capital for “scaling up production and accelerating collaboration with customers” to bring its yeast-fermented dairy products to market, according to chief commercial officer Lucie Rein.

The Zurich-based startup aims to file dossiers for regulatory approval from the US FDA and the European Food Safety Authority this year, with plans to launch its yeast-derived cream – both across foodservice and retail – in the US next year, and in the EU by 2026. This is because it finds Europe’s regulatory environment – said to be the strictest in the world – too slow for its growth and expansion goals, with the US pathway much more expedient and efficient.

“This funding validates our innovative approach and enables us to introduce our revolutionary yeast cream to the market,” said Cultivated Biosciences CEO Tomas Turner. “We aim to make alternative dairy products appealing to traditional dairy consumers, not just to reduce CO2 emissions from dairy production but also to tap into a multi-billion dollar market opportunity.”

Scaling up will drive Cultivated Biosciences towards price parity

Founded in 2021 by Turner and chief technology officer Dimitri Zogg, Cultivated Biosiences takes a unique approach to dairy alternatives. While most fermentation-derived dairy companies are developing proteins to mimic those found in dairy (like whey and casein), the Swiss startup is tapping into fats to deliver a better flavour and textural experience.

It uses biomass fermentation with an oleaginous yeast strain, which accumulates fat during growth. The resulting fat provides the lipids and texture to alt-dairy formulations. Cultivated Biosciences argues that this is a step up from existing non-dairy products on the market, which feature a combination of emulsifiers and texturisers that “don’t exactly replicate the dairy experience”.

Its patented yeast-derived cream, in contrast, is said to mimic “the creaminess, functionality and colour” of its conventional counterpart, alongside improving the texture and stability of non-dairy products, without affecting the flavour.

The functionality is key – a four-country, 1,500-person survey by Kerry last year revealed that sensorial attributes have the most room for improvement for milk alternatives, with 34% of respondents citing it. Moreover, 76% of consumers favour ‘a nice creamy mouthfeel without the dairy’, and 77% find non-dairy products more appealing if they have ‘better body and texture’. The report noted that mouthfeel was one of the major challenges for manufacturers to overcome, with people looking fora cleaner taste experience with a creamy, fatty mouthfeel that replicates conventional dairy.

The cream ingredient – which contains 1% of oat flour – features a microstructure of yeast lipid droplets that resemble milk fat droplets. “Our creamer formulation has the same amount of fat and more protein than the commercial products,” Rein said when asked about the health credentials of the ingredient. “The protein comes from our cream.”

Eduard Meijer, managing director at Navus Ventures, said the ingredient has a “great taste, mouthfeel, versatility and functionality”, and can significantly improve dairy analogues, “with a technology that has the potential to scale economically”.

The company has been able to scale up production to 1,500-litre bioreactors. The latest investment will help it expand manufacturing even further, driving down its product costs. Cultivated Biosciences says it will eventually be possible to produce its cream at price parity with dairy cream at scale, earmarking 2027 for that target.

A B2B model for a range of alt-dairy products

Plant-based companies like Silk, Califia Farms and Country Crock all produce their own versions of vegan cream, a $413M market. Cultivated Biosciences’ fat is designed for integration into consumer products, with plans to supply to the food industry through a B2B business model – but it can be used in multiple liquid and semi-liquid applications, including milk, ice cream (where it has validated a strong value proposition), and coffee creamers.

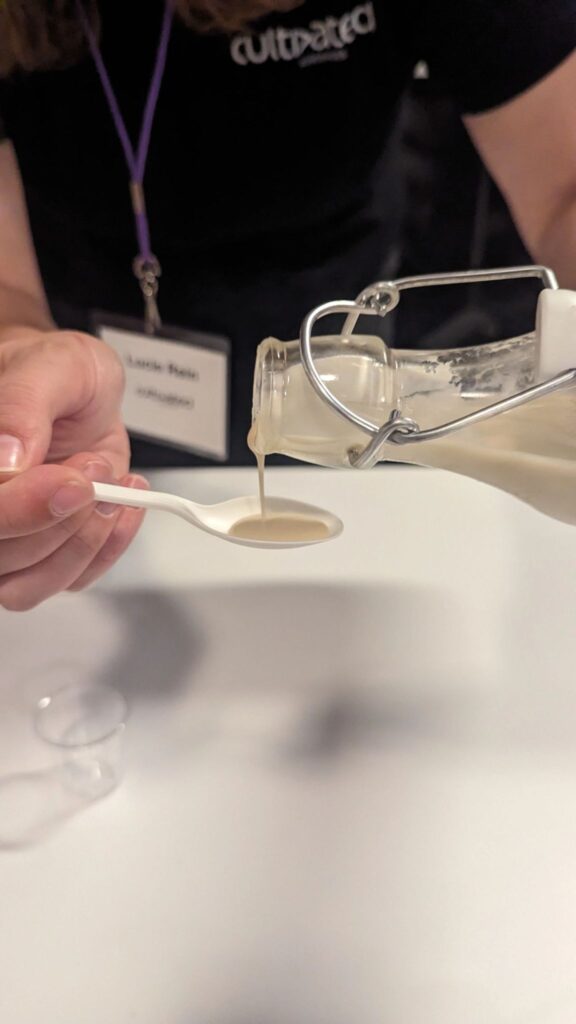

In fact, it demonstrated the latter as a first proof of concept at a MISTA trade event in San Francisco in December. The creamer – which combined its fat ingredient with plant protein, sugar and natural flavourings – was described as “creamy, clean label, white and stable in coffee”, which the company adds is something not offered by “commercially available plant-based creamers”. It additionally bypassed the common problem of curdling in lighter-roasted coffees, without any additives.

Plus, there are environmental advantages too. An internal life-cycle assessment by the startup revealed that its yeast-based cream has a 90% lower carbon footprint than conventional dairy.

Unlike precision-fermented products, Cultivated Biosciences’s fat isn’t molecularly identical to dairy, but instead aims to achieve “functional and sensory parity”. The resulting cream is lactose-free and vegan, but there are still some legislative barriers to overcome. There is no regulatory definition for ‘dairy-free’ in the US, but the rules for ‘non-dairy’ mean that products like cream and coffee creamers can still contain dairy proteins like casein.

This can be confusing to customers. “We are still figuring this one out,” said Rein. “It will be different in Europe and the US. We will be very clearly dairy-free and not using the ‘non-dairy’ term.”

Other companies innovating with fermented fats include Zero Acre Farms, Yali Bio (both US), Nourish Ingredients (Australia), NoPalm Ingredients, Willicoft (both Netherlands), Colipi (Germany), and Clean Food Group (UK). Meanwhile, New Zealand-based Miruku is leveraging molecular farming tech to produce “bio-similar dairy proteins and fats” at a much cheaper cost.