4 Mins Read

Developed by The Hong Kong Research Institute of Textiles and Apparel (HKRITA) in partnership with the H&M Foundation, the hydrothermal separation system (The Green Machine) will manufacture garments for one of H&M’S brands Monki, a youth-focused fashion brand, creating its first-ever circular line made out of recycled polyester.

Established in 2018, the Green machine was first set up as a small scale machine. After testing this concept out two years ago in Tai Po, Hong Kong, HKRITA has now established what it claims to be the first industrial-scale system in Indonesia.

The reason behind setting up this machine was because HKRITA and the H&M Foundation observed that there were no commercially viable separation and recycling technologies available in the fashion industry for blended fabrics like cotton and polyester.

As a fashion brand we need to do our part when it comes to closing the loop. With eyes wide open Monki will walk into this climate- decade and be part of the solution. If we can prolong the life of our products for as long as possible and decrease usage of virgin sources, it’s a huge step in the right direction

Jenny Fagerlin, Sustainability Director at Monki

The work for the idea to solve this problem had begun in 2016 and in 2017, one year after the H&M Foundation collaborated with HKRITA, researchers discovered a hydrothermal process that could completely separate and recycle polyester and cotton blends into new fibers and cellulose powder. According to the H&M Foundation, unlike other processes, the Green Machine process is gentle ensuring zero damage to the fibers thus preserving the quality of the fabrics.

In 2020, Monki released its first collection made from the Green Machine technology, created at the smaller system in Hong Kong. Based on this, a larger pilot programme will be undertaken in 2021. It will be operated in PT Kahatex, an established textile manufacturer in Indonesia.

Erik Bang, Innovation Lead of H&M Foundation mentioned that the Green Machine is a technological milestone as well as an economical one. “We are close to not only recycle blend textiles at scale but also making it affordable for all, killing the myth of sustainability being a costly compromise. We can’t settle for less (than inclusive solutions) if we’re serious about stopping climate change.”

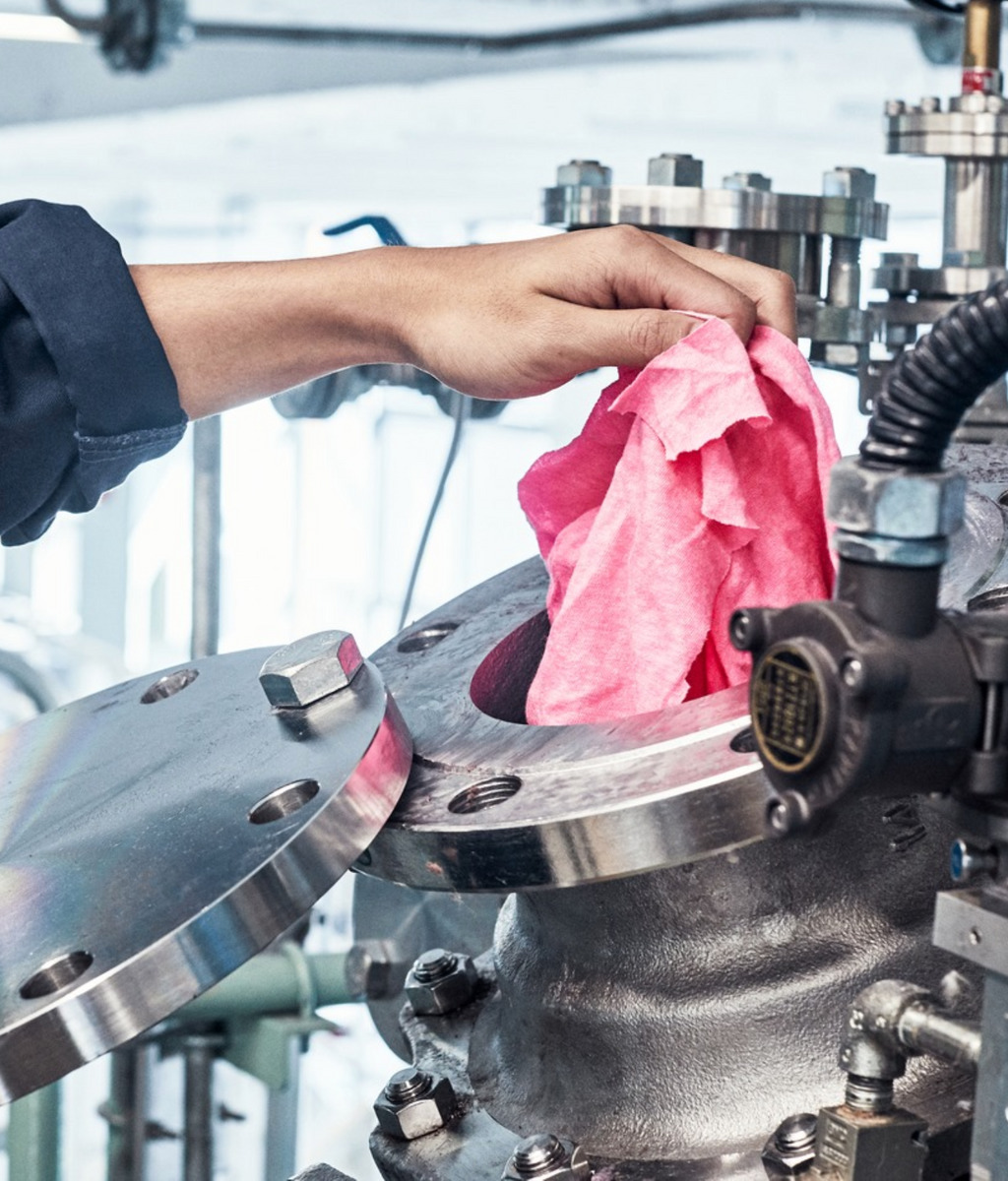

The entire system runs on just heat, water, pressure, and a biodegradable green chemical. According to the H&M Foundation, it doesn’t create secondary pollution as it’s a closed-loop where all the elements are reused time and again.

The industrial-scale Green Machine will be able to process up to 1.5 tons per day. PT Kahatex will first start by using waste produced from manufacturing like difficult-to-recycle blended fibers, yarn, and fabric as feedstock to create garments.

The new normal has driven us in a green direction. In collaboration with our partners in the supply chain, we have created a system that at scale will achieve two very important aims: first, it will provide a new and commercially viable industrial recycling solution and second, it will help us move closer to a sustainable future

Edwin Keh, Chief Executive Officer of HKRITA

This operation also aims to optimise the parameters of the system so that in the future, the new Green machines will work more smoothly.

Andy Trisna, Director of PT Kahatex explained that the machine will reinforce the values of sustainability for brands and customers in the fashion industry. “We were keen to work together with H&M Foundation and HKRITA to develop at an industrial scale system to recycle more materials. I hope that the hydrothermal system can be scaled-up even more and become a widely accepted approach to a more sustainable fashion industry.”

Sustainability Director at Monki, Jenny Fagerlin elaborated on how fashion brands must do their part to closing the loop. “With eyes wide open Monki will walk into this climate- decade and be part of the solution. If we can prolong the life of our products for as long as possible and decrease usage of virgin sources, it’s a huge step in the right direction.”

For this innovation, the Green machine has received a couple of awards including the Gold Medal in the 46th International Exhibition of Inventions of Geneva (2018) and the Gold Award in Asia International Innovative Invention Award (2019).

Edwin Keh, Chief Executive Officer of HKRITA mentioned how the new normal has driven us in a green direction. “In collaboration with our partners in the supply chain, we have created a system that at scale will achieve two very important aims: first, it will provide a new and commercially viable industrial recycling solution and second, it will help us move closer to a sustainable future.”

H&M has been working hard on sustainability to fight their fast fashion reputation, with a range of measures implemented to advance circularity, For instance, as part of its Bottle2Fashion project, H&M recently collaborated with Danone Aqua and transformed plastic bottle waste from the shores of Indonesia into recycled polyester, the same material used for its latest kidswear collection.

In October last year, H&M added a ‘Looop’ system in one of its stores to invite customers to witness how the brand’s container-sized machine recycles their own textiles into something new thus promoting a closed-loop fashion economy.

All images courtesy of H&M Foundation