Looking To Start a Future Food Startup? Singapore’s Protein Innovation Centre Is The Launchpad You Need

5 Mins Read

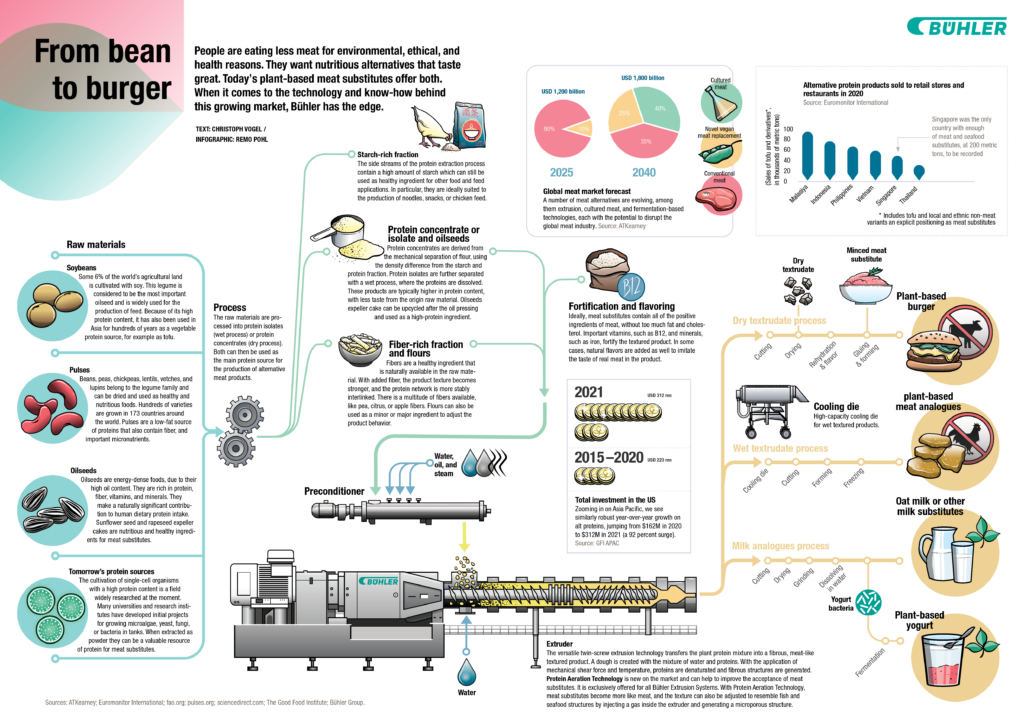

With its world-class innovation centre, a Scale It Up Innovation Challenge, and pioneering protein aeration technology, leading machinery maker Bühler is helping global meat substitute startups supercharge their production and scaling journey.

LAUNCH – Singapore as the Launchpad for Your Vegan Brand

Singapore has built up one of the most exciting food tech industries in the world- some call it the world’s food tech capital. This moniker was all but solidified back in December 2020, when the tiny island nation became the first country in the world to give regulatory approval for the sale of cultivated meat- that is animal meat grown in a bioreactor from live animal cell cultures. A short few years later, founders from all four corners of the globe are leaving their home countries to establish a base in the Lion City state to pursue alternative protein dreams. As of 2022, 36 food tech startups are headquartered in Singapore, and collectively they have collectively raised over $214 million.

Early-stage food tech entrepreneurs need the ability to conduct research, run pilots, and test manufacturing above all else. Spurred on by the Singaporean government’s 30 by 2030 plan, which supports local food production technology, the little red dot has built up one of the most dynamic B2B plant-based protein ecosystems around, with infrastructure on all levels from world-class science & research talent to pilot production facilities to co-manufacturers and local ingredient sourcing, making it the ideal launchpad for a new vegan meat entrepreneur.

Companies building supply chains and doing R&D in Singapore include Swedish oat milk pioneer OATLY, Californian precision fermentation leader Perfect Day as well as homegrown brands like Next Gen Foods, maker of TiNDLE plant-based chicken, and plant-based nutrition company Growthwell Foods.

Young startups looking to test high moisture extrusion formulations are also able to leverage Buhler’s partnership with SGProtein, a Singaporean contract manufacturer of plant-based meat products that boasts a 500kg/hr extruder.

TEST – Get a Market Ready Product in Mere Days with Bühler

Possibly the most expensive part of a food tech startup’s Capex budget is a factory build-out. Building out your own facility takes years, and millions in funding and comes with huge regulatory and legal headaches. All the while, you are not able to test or iterate your product, which is the most important part of the first few. But what if the machinery you buy is not a fit? And what about factory running costs? Not to mention rising labor charges.

Your job as a founder in those early days is to build, test and improve, ideally without wasting time or capital. Buhler’s Protein Innovation Centre empowers you to do all that and more (get inputs from industry experts and know-how from veteran food players) at a fraction of the cost and stress of investing in your own.

The Protein Innovation Centre, a collaboration between leading food equipment manufacturer Bühler and flavoring specialist Givaudan offers food tech founders and their teams a one-stop shop to innovate novel plant-based meat foods working with dry and wet extrusion techniques. The two Swiss giants’ combined expertise means that product development challenges can be avoided and shorten new product lead times. Startups can trial, test, and taste products in less than a week. To a young company, this kind of opportunity is life-changing.

“It was exactly what we were looking for, in terms of scale, in terms of availability and capability. For a pilot scale extruder that has the latest technologies attached at that particular scale..there is very few available in the region. It’s the best facility I have seen in the region, and it’s quite cost competitive, so it was a no-brainer!”

Professor Roman Buckow, CTO, All G Foods

INNOVATE – Protein Aeration Technology: The Next Generation of Meat Substitutes

Beyond nutrition, accessibility, and price, a plant-based meat alternative needs to deliver on texture and taste. In fact, consumers often cite poor mouthfeel or lack of deliciousness as pivotal reasons they may not make repeat purchases of animal-free replacements.

Decades of machinery expertise means Buhler can leapfrog over available technology in the market and offer plant-based meat startups a crucial differentiation when creating high moisture extruded products: Protein Aeration Technology, the company’s latest equipment innovation dubbed by in-house researchers as the future of plant-based meat technology. The aeration process involves gas being injected into the product during the extrusion process to create micro “pocket” structures that result in increased flavor absorption, more authentic color, and biting properties that mimic meat and fish. The aeration technology even reduces raw material costs and offers higher nutritional content.

“Bühler made it possible for us to scale up to an industrial level.”

Eric Stirnemann, Planted co-founder

GROWTH – Scale It Up: The Key To Changing How The World Eats

Bühler and partners Givaudan and Cargill have joined forces to support food tech startups beyond just providing manufacturing expertise. The Scale It Up Innovation Challenge is a niche program designed for entrepreneurs solving moonshot food system problems. Are you creating new plant-based meat with a unique taste profile? Or dreaming up novel protein sources for food ingredient companies that offer new opportunities along the food value chain? Do you have an animal-free product that is working to offer a high-fidelity experience for meat and dairy consumers?

Where most food accelerator and incubator programs are limited to theoretical learning and digital resources, the Scale It Up Challenge is practical, iterative, and functional. It’s a chance to upskill yourself and your team in key production areas such as extrusion, and formulation.

The program also provides support in marketing, operations, and sourcing. Startups can acquire training around all these verticals and be supported by mentorship and feedback from the organizers, build out a network of b2b service providers, refine their proof of concept at Bühler and Givaudan world-class facility, the Protein Innovation Centre, and scale to commercial readiness within a few short months. It’s hard to imagine a better opportunity for an emerging food tech founder.

All imagery courtesy of Bühler.

This is a Green Queen Partner Post.