Researchers Are Using Baker’s Yeast to Turn Carbon Dioxide Into Protein & Folate

4 Mins Read

Scientists have discovered a way to turn gases into yeast that contains more protein than beef and enough folate to meet your daily requirements.

What if acetate and carbon dioxide could help you meet your daily nutritional needs?

Researchers at the University of Tübingen in Germany are proposing just that, having found a way to make yeast using carbon dioxide, oxygen and hydrogen.

Using a process similar to beer brewing, the scientists fed microbes with these gases and acetate (a compound found in vinegar) instead of sugar to produce protein and folate (also known as vitamin B9).

The process is based on renewable energy and eschews the need for farmland, resulting in much lower emissions and an efficient way to produce food to feed a population that is expected to grow to 10 billion by 2050. The resulting yeast can be used as a base for vegan meat analogues, helping decarbonise the livestock sector with carbon.

From power to protein to vitamins

The study, published in the Trends in Biotechnology journal, is derived from a “power-to-protein technology” that the same scientists developed to produce microbial protein from renewable energy and CO2.

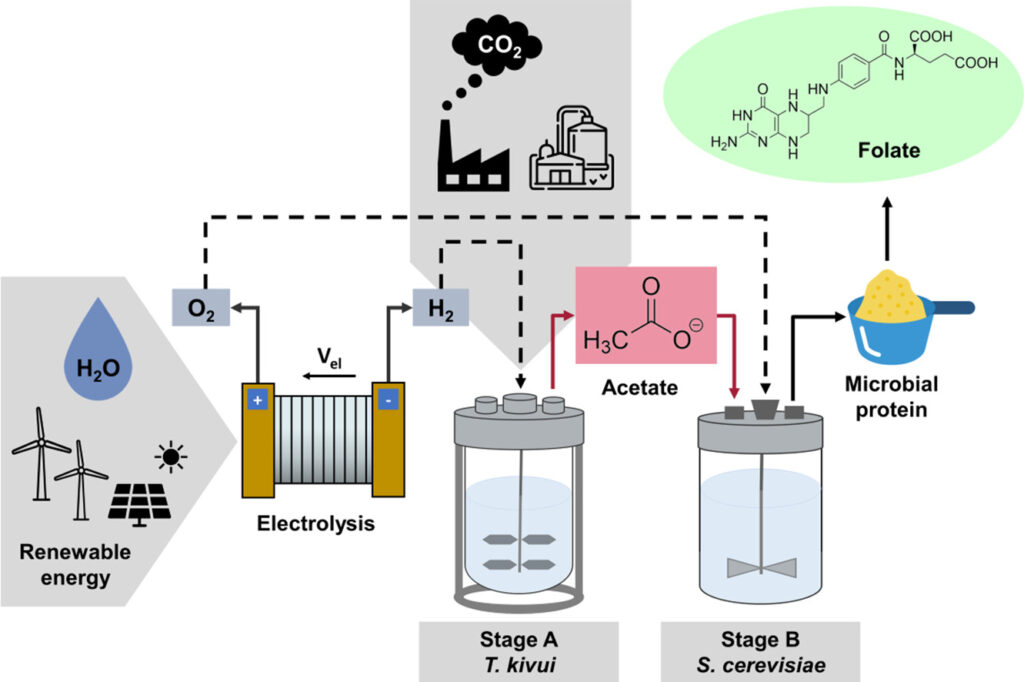

Here, the bacterium Clostridium ljungdahlii was used to reduce carbon dioxide with hydrogen into acetate, which is combined with oxygen and transformed into proteins by Saccharomyces cerevisiae, or baker’s yeast. (The hydrogen and oxygen can be produced via electrolysis, or using renewable electricity to split H2O into H2 and O2.)

But the first step only worked through continuous vitamin supplementation. “Humans can’t live on proteins alone,” explained lead author Largus Angenent. “So we wanted to produce B9 at the same time.”

In the “power-to-vitamin” experiment, Angenent and his team replaced C. ljungdahlii with Thermoanaerobacter kivui, a more robust bacterium, in the two-stage bioreactor system. In the first step, T. kivui converts hydrogen and CO2 into acetate.

In the second stage, the baker’s yeast is fed on oxygen and this acetate to make large quantities of protein and vitamin B9. “We knew that yeast could produce vitamin B9 on their own with sugar, however, we didn’t know if they could do the same with acetate,” said Angenent. “Since we’re no longer adding vitamin B9, we’re certain that it is produced in the process.”

Acetate-fed yeast was found to produce around the same amount of folate as yeast that eats sugar – only 6g or 0.4 tablespoons of the harvested dried yeast can meet the daily requirement for the vitamin.

Meanwhile, six tablespoons or 85g of this nutritional yeast provides 61% of daily protein needs. This is higher than beef (34%), pork (25%), fish (38%), and lentils (38%). That said, the yeast needs to be treated to remove gout-inducing compounds when consumed in excess. Even after that, it meets 41% of the protein needs per day.

Addressing food security and climate change

For Angenent, the main goal of the research is to reduce meat consumption. Globally, livestock farming accounts for 57% of the food system’s emissions and takes up 80% of land, despite only supplying 17% of the world’s calories and 38% of its protein. That is an inefficient form of agriculture, and a threat to food security in the long term.

“Our product isn’t yet a finished foodstuff, but the food industry can use it to develop foods,” said Angenent, who claimed that the process has “zero or negative net-carbon emissions”. He added: “I believe consumers will get used to new products. This also comes about through pricing.”

He suggested that this won’t outcompete farmers. Livestock producers are already under stress to meet the world’s growing protein demand, and doing so at current volumes in the long term is untenable. Meanwhile, it will free up land to produce more vegetables and planet-friendly crops, as well as allow them to protect soil and nature.

“The fact that we can make vitamins and protein at the same time at a pretty high production rate without using any land is exciting,” said Angenent. “The end product is vegetarian/vegan, non-GMO, and sustainable, which could appeal to consumers.”

His team now plans to optimise and expand production from lab to commercial scales, conduct food safety studies and techno-economical analyses, as well as work out market interest for the gas-fed yeast.

For the latter, it doesn’t need to look too far – there are several startups leveraging gas proteins, including Air Protein, Farmless, Arkeon Biotechnologies, and Solar Foods. The latter, which feeds microbes on CO2, oxygen and hydrogen, has already been in the Singapore market, and is now making its move into the US.

“The growing world population is threatened by malnutrition, especially in countries that suffer from drought and whose soils are low in nutrients,” said Angenent, highlighting the yeast’s food security benefits. “In places like this, substitute products, such as ours, could improve the food situation.”