3 Mins Read

Perth-based startup Cass Materials has recently developed a new edible scaffold, which can be used by cellular agriculture food techs to manufacture cultivated proteins. The company’s biodegradable scaffolding, which is derived from nata de coco, can provide the matrix for animal cells to grow around, making it a suitable replacement for gelatin-based fibres that many lab-grown meat developers still rely on.

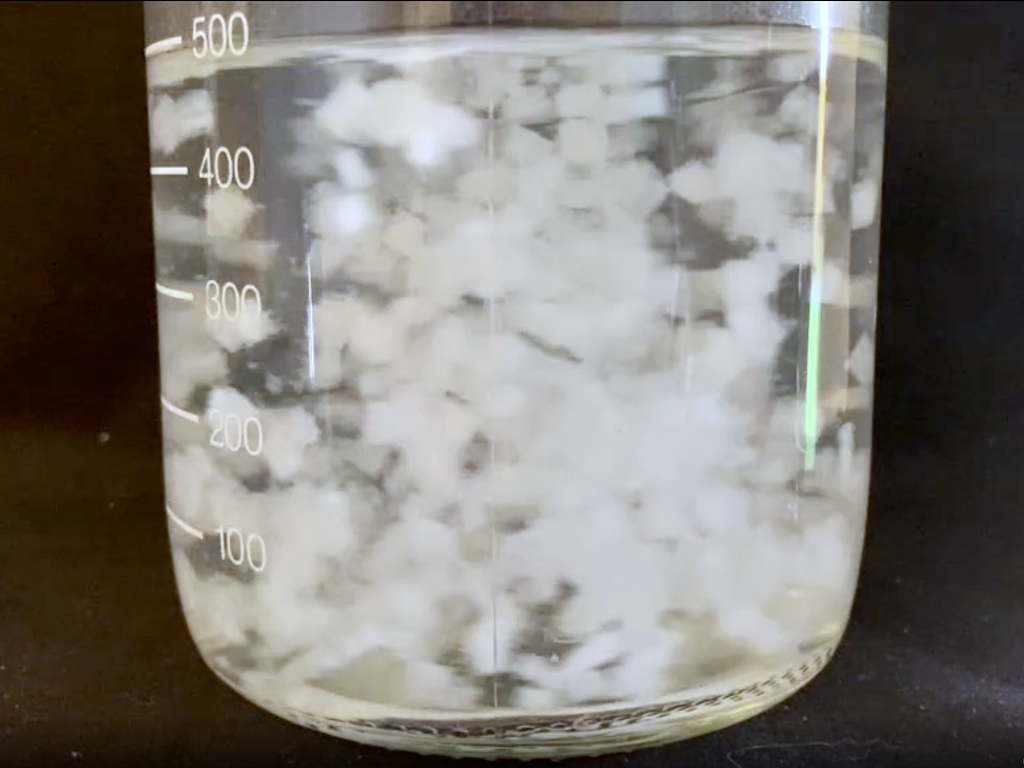

Founded this year by Gary Cass, Cass Materials is an eco-tech materials startup working to produce natural and biodegradable material alternatives for food and medical industries. Using the natural fermentation process in the production of the coconut jelly dessert nata de coco, the company has developed a nanocellulose fibre matrix that meat cells can grow around.

Because it is made from 100% bacterial nanocellulose, it is edible and completely biodegradable. The company says that it can be manufactured according to different shapes and sizes to suit different cell-based meat products, and is also tasteless in itself, making it easy for food techs to adapt to using the scaffolding.

Structural scaffolding is necessary in the lab-grown meat making process, because recreating cuts of animal meat with complex cell structures, such as steak, requires a 3D matrix to support different types of cells, from muscle to fat. While plant-based scaffolding has emerged in recent months, many cultivated food techs have used scaffolding derived from beef gelatin, a collagen obtained by boiling animal carcasses leftover in slaughterhouses.

“The BNC scaffold fibres are similar in physical dimensions to mammalian collagen fibres,” says the startup, making it a suitable alternative for successful scaffolding of animal cells in culture.

Other plant-based scaffoldings include one made from textured soy protein. In April, food scientists found that the edible byproduct of soybean oil extraction can be harnessed to recreate the texture of a meat bite in lab-grown beef.

Meanwhile, Brussels-based Tiamat Sciences is using plant-based molecular farming technology to create a number of recombinant protein ingredients, including enzymes, antibodies, scaffolding and growth factors at a fraction of the price compared to their competitors.

These new scaffold technologies are crucial to help scale-up cell-based meat products towards market readiness. Along with plant-based substitutes, which have already become hugely popular amongst consumers globally, cultivated proteins are one of the core food technologies that will help bring about a more sustainable, ethical and safe food system.

Currently, raising livestock for meat accounts for around 18% of global greenhouse gas emissions, uses around 70% of agricultural land, and in the process drives deliberate deforestation and biodiversity loss.

Alternative proteins not only come with a smaller environmental footprint, but are also safer and more crisis-resilient. Amid the coronavirus pandemic, consumers are choosing plant-based proteins more than ever before, while governments look ahead to support cultivated meat innovation to shield against external supply shocks and bolster food security.

In June, the Chinese national advisory body discussed cell-based meat development as a potential key to ensuring the future of China’s protein supply, while Japanese authorities announced plans to introduce legislation for the industry, with the view to push forward mass industrialisation and production of alternative proteins in the country.

Lead image courtesy of Cass Materials.