Audra Labs Bids To Bring Meat-Free Streaky Bacon And Chicken Fillets To Singapore

3 Mins Read

Audra Labs, the plant-based meat enterprise that’s an offshoot from the Agency for Science, Technology and Research (A*Star), is headed by former principal researcher Dr. Andrew Wan. Formerly of the Bioengineering and Nanotechnology division, he has experience in the creation of fibres for tissue engineering.

The process of tissue engineering led to Wan being inspired to use similar techniques for plant-based meat construction. His breakthrough came during a 2020 lockdown when he decided to replicate the tissue process with plant molecules instead of human protein.

The making of plant-based meat

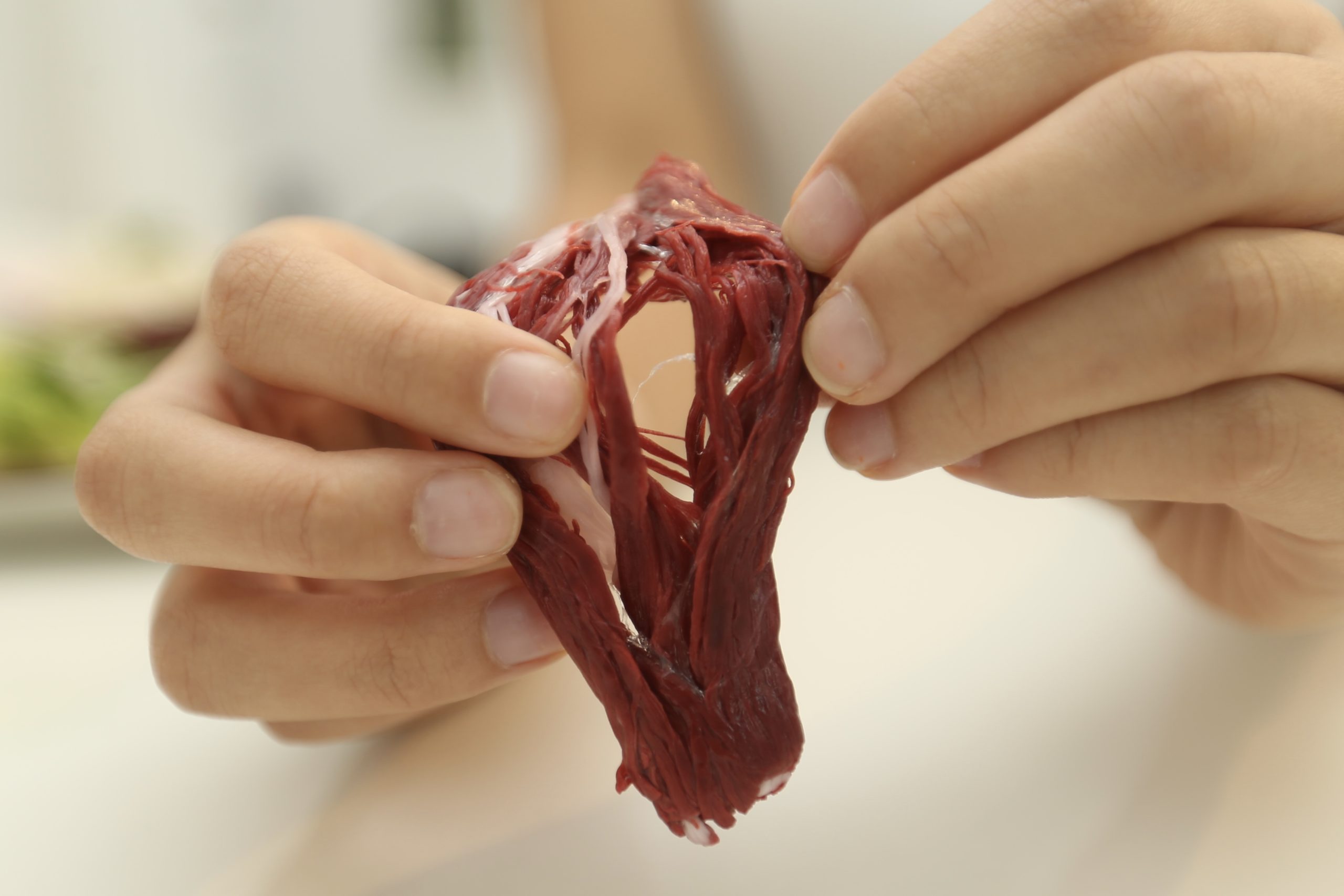

Wan successfully produced a malleable polymer using plant molecules. “Once we have that, we can then combine or assemble the fibres, which would then become the final product that visually looks and physically feels and tears like meat,” Wan told The Straits Times. “However, in order to imbue flavouring into the product, it often has to be ground into smaller chunks, and then reassembled later on, explaining why plant-based meat options are often sold in nugget or patty forms.”

Using engineering techniques to bring plant proteins and natural flavours together into fibres allows Audra Labs to focus on whole-cuts including bacon and fillets. The proprietary fibre technique creates similarly realistic muscle and fat threads, but without the cost-prohibitive technology requirements. Being able to lower the cost of plant-based meats, while creating regionally appropriate styles, is something Wan is emphatic about.

“As a locally grown start-up, we are aware of how passionate Singaporeans are when it comes to their food,” he told The Strait Times. “By reproducing the texture and taste of plant-based meat in cuisines which locals are fond of, like chicken rice, we could perhaps make a difference in promoting consumer acceptance towards alternative meat products.”

Coming to market

The initial product launch is slated for early or mid-2023 and no format has been confirmed yet. There is still work to be done on flavour and texture, to authentically recreate the experience of biting into real meat. There are already plans to offer the technology on a B2B basis, with “several multinationals” discussing incorporating the tech into their plant-based products. Eventually, the company will move into the cultivated arena.

Audra Labs’ fibre texturing process could be used to improve a variety of alternative proteins. Cultivated meat will be a natural step, according to Wan, as he has worked with human cells previously.

Working on whole-cuts

Vegan whole-cut meats are a niche area gaining traction. Last month it was announced that Israel’s Redefine Meat has scooped $135 million to bring its total raised to $180 million. The 3D printed plant-based meat specialist already serves its whole cut products in more than 200 domestic restaurants, with locations in the U.K., Netherlands and Germany also confirmed. Further global expansion will be sought with the new funding.

Bringing three trends into one place, Keen 4 Greens has just announced the closure of a €1.8 million seed funding round designed to facilitate investigation into whole-cut mycelium clean label vegan meats. Beef and bacon have been named as analogues the company wants to develop, once production facilities have been successfully scaled. The company currently uses wheat and pea protein for its vegan mat products, but it, like many others, identifies mycelium as a future food.

Lead photo by Samuel Ang for Audra Labs.