Italian AI Startup Brews $10M to Turn Microbes Into Affordable Animal-Free Proteins

4 Mins Read

Italian startup Arsenale Bioyards has raised €9.5M ($9.8M) to scale up its AI-led precision fermentation process and lower biomanufacturing costs by 90%.

Arsenale Bioyards, an industrial biotech firm based in Milan, has closed a €9.5M ($9.8M) seed funding round to scale up its biomanufacturing process and make sustainable food and cosmetics significantly more affordable.

The investment was led by Planet A Ventures and byFounders, with additional participation from CDP Ventures, Acequia Capital, Plug N Play, Grey Silo Ventures, and industrial family offices.

The firm combines artificial intelligence (AI) with advanced hardware to form an end-to-end precision fermentation platform for biomanufacturing, from lab scale to industrial production. The tech can accelerate commercialisation, reduce risks, and bring down costs by up to 90%, solving some of the industry’s biggest bottlenecks.

“We saw Arsenale’s potential early on,” said Christoph Gras, co-founder and general partner of Planet A Ventures. “This is a fundamental rethink of how biomanufacturing scales. By making production cost-competitive and standardised, Arsenale turns biomanufacturing into an investable asset class while enabling industries to move away from animal- and petrochemical-derived products at scale.”

How Arsenale is revolutionising biomanufacturing

Arsenale was founded in 2023 by a five-strong team chock full of industry experience, comprising Matteo Zanotto, Gordana Djordjevic, Massimo Portincaso, Niels Agerbaek, and Arnaud Legris. They have worked in deep tech, AI, and pharma sectors, including with companies like Novo Nordisk, Xellia, Perfect Day, and Boston Consulting Group.

The company’s tech is centred on precision fermentation, which combines traditional fermentation with the latest biotechnology advances to efficiently produce a compound of interest, like a protein, flavour molecule, vitamin, pigment, or fat.

This has been used by the pharma industry for decades – it’s how insulin and many vitamin supplements are made – but its use in food and cosmetics has been hindered by high costs. To address that, Arsenale uses a “neo-industrial” approach to biomanufacturing.

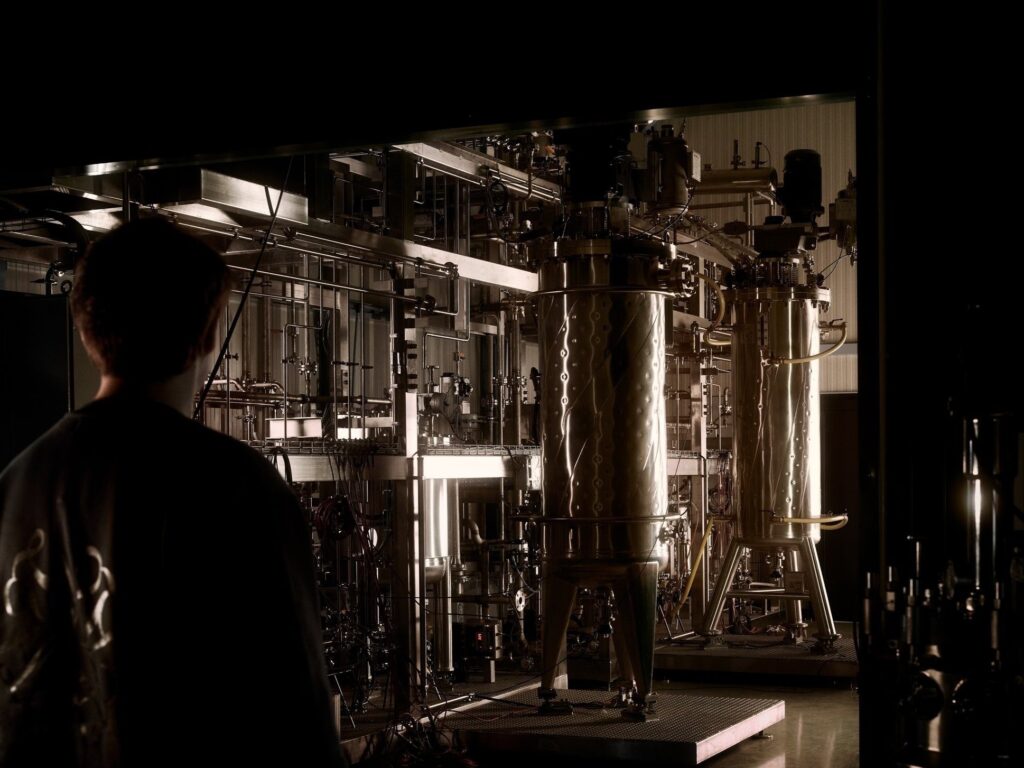

It operates a pilot facility called ⍺-Yard in the Pordenone province, which has a 1,000-litre fermentation capacity, courtesy of four bioreactors of varying scales. The Piccolo suite comprises two micro-bioreactors to design processes and organisms on a benchtop scale, while the two Magnum bioreactors have a 500-litre capacity and offer advanced sensing capabilities.

Then there are the Bioyards, which house a six-strong suite of modular industrial bioreactors with a capacity of over 50,000 litres each to enable cost-effective “scaling out”, as opposed to “scaling up”. These, combined with the Design@Scale AI model, drastically reduce both capital and operating expenditures.

“Arsenale is not only imagining the bio-economy of the future – we are building it today, with operational facilities and proprietary technology,” said Portincaso, who is the startup’s CEO.

The startup, which also has an office in California, will use the capital to expand its infrastructure and speed up its commercialisation roadmap for food and cosmetics. “This funding reinforces our ability to drive measurable change and underscores our aspiration to build a new generative, biology-driven industrial paradigm,” he added.

A Bessemer Moment for precision fermentation?

Arsenale has highlighted the four fundamental precision fermentation challenges it hopes to solve. First, it’s dominated by biopharma, a highly regulated industry that creates expensive cost structures unsuited to industrial applications. Secondly, value creation here is lab-centric and academia-driven – this makes it “almost impossible” to predict microbes’ behaviours and yield on an industrial scale.

Meanwhile, fragmentation across design, scale-up and manufacturing causes friction and inefficient processes. And finally, the industry faces data bottlenecks, with inconsistent and limited data hindering learning through the use of AI and machine learning.

Arsenale argues that it’s time for precision fermentation’s Bessemer Moment, a reference to Henry Bessemer’s breakthrough in reducing steel costs by 85% via process and engineering innovation.

Its process integrates industrial conditions into the lab, allowing companies to design at scale from day one and cutting costs significantly versus contract manufacturing approaches. Plus, the AI-driven process optimisation and software-led approach can help producers move from lab to commercial scale in a “fraction of the time”.

The $10M investment is a sign of confidence from investors who have cooled on the climate tech sector, where funding dipped by 38% last year. This was partly a result of a shift in interest towards AI, which attracted over three times as much venture capital. Within the food tech sector, where plant-based and cultivated protein companies witnessed alarming declines, fermentation stood out with a 43% hike in investment.

By combining two highly prized sectors in the eyes of investors – AI and precision fermentation – Arsenale has the ingredients to engineer food’s Bessemer Moment.