Exclusive: Aqua Cultured Foods Earns US Regulatory Approval for Fish-Free Fermentation-Based Seafood

9 Mins Read

Aqua Cultured Foods has obtained self-affirmed GRAS status in the US, and will begin selling its cellulose-based seafood analogues made via fermentation to restaurants next month.

Fish-free seafood made from fermentation will soon be on restaurant menus in the US, with Aqua Cultured Foods receiving the regulatory greenlight for its cellulose-based analogues.

The Chicago startup has earned self-determined Generally Recognized as Safe (GRAS) status for its raw ingredient – made from its proprietary biomass fermentation tech – to be used in any food products.

Its first products are tuna and scallops, which boast clean-label formulations and short ingredient lists, two factors that have become increasingly important to consumers. Optimised for raw applications like sushi, tartare and ceviche, the cellulose-based analogues will be available to restaurants at either the same price or cheaper than conventional seafood at wholesale. The startup will roll out the products at fine-dining restaurants in the Chicago metropolitan area next month.

“Our products are very clean-label with minimal ingredients. We have created a cost-effective production process by leveraging learnings and equipment from other industries that use fermentation,” Aqua Cultured Foods co-founder and CEO Brittany Chibe tells Green Queen.

“Thus, by targeting premium, raw cuts of seafood, we can achieve positive unit economics, which is largely unheard of at pilot scale.”

How Aqua Cultured Foods makes seafood from cellulose

Aqua Cultured Foods’ low-capex production process is its “secret sauce”, according to Chibe. “Our patented process begins with a proprietary consortium of microbes. We grow cellulose fibre into whole-cut filets that naturally resemble the appearance and texture of raw seafood,” she explains.

“Once the filets reach the preferred level of thickness, we pasteurise them and combine them with plant-derived flavours and colours to replicate tuna and scallops. Think of a buttery scallop or the umami tang of tuna. Once marinated, Aqua is ready for any chef to prepare and plate.”

It does not require any expensive equipment or multiple processing steps – instead repurposing apparatus tapping into industries like beer brewing and vertical farming– and Chibe says the process can be replicated anywhere in the world.

To further optimise its manufacturing, it partnered with Boston-based synbio firm Ginkgo Bioworks in March. “With Ginkgo, we will further optimise our microbial consortium to elevate the quality and consistency of our products,” Aqua Cultured Foods CSO Stefan Baier told Green Queen at the time. “By optimising our strain, we could grow different scaffolds with tailored textures and improve nutrition beyond a good source of fibre.”

In 2023, the startup acquired a 5,000 sq ft food-grade facility in Chicago for its pilot plant, which can produce 5,000 lbs of raw product in a 500 sq ft room. This is enough to cater to about 20 Michelin-starred restaurants.

“Seafood is a very confusing category, with little to no visibility of the supply chain, and category-specific terminology such as ‘wild-caught’ vs ‘farm-raised’ raises more questions than answers,” says Chibe. The majority of consumer spending on seafood takes place out of the home for momentous, special occasions – particularly because it’s expensive.”

But she points out that 70% of seafood in the US is imported, which results in “inconsistent supply and varying quality” for restaurants. “Aqua is a locally-made, consistent ingredient with a completely sea-free supply chain and gives chefs the same creative freedom they have with real seafood,” she says, calling its scallops and tuna “the pinnacle of indulgence and celebration in raw applications”.

Clean-label high on the agenda

In April, a decade-long proprietary study by ingredients giant Ingredion and Clear Seas Research revealed that 99% of European manufacturers believe clean-label products are not just an advantage, but a cornerstone of their business strategy. In fact, over the next two years, these products are set to make up 70% of portfolios (up from 52% in 2021).

Aqua Cultured Foods’ seafood analogues – which have a six-week shelf-life – are a testament to this. The five-ingredient scallop rounds, for example, contain cellulose, water, soluble corn fibre, salt and natural flavouring. And the vegan tuna blocks add to that with trisodium phosphate (which helps retain moisture and flavour), lactic acid (a natural preservative), calcium lactate (which keeps foods stable and firm, and adds calcium), pea protein, and a beet-derived colour to match the deep red hue of ahi or bluefin tuna.

A survey by the International Food Information Council (IFIC) this year found that 66% of seafood consumers prioritise nutrition and health, with frequent eaters showing an even higher inclination (78%). The scallops contain 5g of fibre per serving, while the tuna has 3g of fibre, plus 10mg each of calcium and potassium. However, there is a negligible amount of protein in both products.

“Expanding the nutritional profile of our products with omega-3s or protein is next on our product roadmap,” says Chibe. “But given our go-to-market strategy, fine dining isn’t necessarily a setting where a consumer is concerned about nutrition and macronutrients; the guest is focused on the enjoyment and experience.”

She points to the fact that we’re overconsuming protein, but underconsuming fibre. “The conversation is shifting away from protein towards fibre. Where protein is a concern, we believe our products can be paired with ingredients like edamame and avocado to create a well-balanced, highly nutritious dish,” she says.

“Many guests miss out on chef-crafted specialty menu items completely because of dietary restrictions. Finally, restaurants can offer an alternative to raw seafood without expecting their guests to compromise. Your vegan friend can enjoy the full Michelin-starred tasting menu, your pregnant friend doesn’t have to give up spicy tuna rolls,” explains Chibe.

“We are leading with raw products due to their remarkable similarity to the natural texture of comparable seafood species and the absence of something like this in the current market,” she adds.

“Due to the high moisture of our products, Aqua is currently best suited for raw dishes but can be heated with a protective coating like a dumpling wrapper or buttery sauce. We love seeing the creative applications our chef partners develop.”

Exploring upcycled and zero-waste processes

The seafood industry has a massive climate impact, with overfishing and industrial aquaculture massively redistributing fish stocks in the ocean. Meanwhile, microplastic pollution, toxic chemical runoff, antibiotic and pesticide use, sea lice, and mercury pollution are among a host of issues leading to the collapse of global fisheries.

A recent global survey by the Marine Stewardship Council found that 30% of people have been eating less seafood in the last two years, with nearly half (48%) concerned about overfishing and 35% worried about climate change impacts. Meanwhile, over 80% of people have changed their dietary habits in this period, and 43% are doing so for sustainability reasons.

Aqua Cultured Foods is currently conducting a life-cycle assessment to assess the impact of its operations and design a zero-waste manufacturing process. “We’ve already made small changes such as the addition of a holding tank to upcycle water throughout our production process to reduce waste,” reveals Chibe.

“One project that has successfully demonstrated the upcycling possibilities of our product was our partnership with Bonhomme Hospitality for our Preview Dinner. In March, Aqua was on restaurant menus for the very first time, as Michelin-starred chef Marcos Campos Sanchez featured Aqua Tuna and Scallops on a six-course menu,” she adds.

“He found a way to showcase the upcycled fermentation media in both cocktails and desserts, displaying the endless possibilities for our products on restaurant menus.”

Why investment in fermentation is bubbling up

Chibe, who has taken over as CEO from fellow co-founder Anne Palermo (who remains an advisor), confirms that Aqua Cultured Foods is not pursuing a ‘no questions letter’ from the Food and Drug Administration, usually seen as a more transparent process with publicly available data that breeds market and consumer confidence.

“Cellulose has existed in our food system for centuries,” she explains. “We pride ourselves on clean-label food made from food. Biomass fermentation itself is not novel, but Aqua’s manufacturing process is unique; thus self-affirmed GRAS was necessary.”

“Should something suggest that we need a full FDA review for additional transparency and market confidence, we would pursue that route,” adds Chibe.

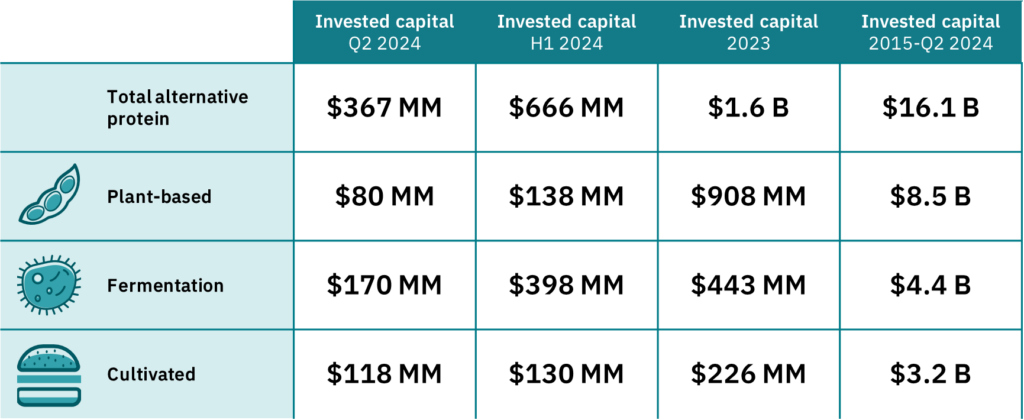

The company, which secured $5.5M in a seed round last year, is finalising plans for a further fundraising effort. Alternative protein startups – much like the food tech sector – have had a hard time raising capital over the last couple of years, with total financing falling by 44%.

But while cultivated meat and plant-based proteins took bigger hits, and recovery has been slow this year, fermentation startups have enjoyed more success. In the first half of 2024, the latter segment has outpaced the other two in funding, bringing in $398M (versus $138M for plant-based and $130M for cultivated meat). This is only $45M short of what fermentation startups secured in all of 2023.

“The industry knows that consumer adoption of alternative proteins won’t take off until products match animal proteins in taste, texture, and price. Plant-based seafood has already entered and led the category, but struggles to gain broader consumer adoption due to missing the mark on these key factors,” says Chibe.

“Cultivated seafood is not yet ready for market entry, as it requires extensive regulatory approval and could take years to achieve price parity,” she adds.

“Fermentation-enabled seafood is the fastest-growing pillar of alternative proteins because of its scalable production, textural similarities, and readiness for market launch. We believe this pillar shows incredible optimism for the future adoption of alternative proteins. Aqua products deliver on taste, texture, and price.”

Alt-seafood players must ‘rally behind a single message’

Despite the rise of fermentation-derived proteins, alternative seafood still accounts for a fraction of both the conventional and plant-based industries.

Analysis by the Good Food Institute in 2023 found that alternative seafood takes up just 1% of the overall seafood share in the US. Its 2024 research doesn’t have separate figures for seafood, but noted that plant-based meat and seafood saw retail sales drop by 12% last year, while prices also increased by 9% (compared to a 3% rise for conventional meat and seafood). And within the plant-based analogue space, vegan seafood currently only accounts for 1% of the market.

“Alternative seafood is still a nascent category with fewer companies tackling this problem,” Chibe says, when compared to beef, pork or chicken analogues. “Additionally, conventional seafood has a health halo and is touted as a healthier alternative to beef, for example.” But this “muddies the facts”, she adds: “A good source of protein or Omega-3s comes at the cost of several health risks.

“Aqua’s mission is to feed our growing planet while protecting the oceans. Once consumers understand not only the dire state of our oceans but the potential health risks of consuming seafood through its current sourcing methods, seafood becomes much less attractive.”

Chibe continues: “Conventional seafood is a confusing category as is; companies creating alternatives need to rally behind a single message and agree on nomenclature. Working together to demystify the category reduces consumer confusion. As I like to say, rising tides float all boats.

“Right now, we have the freedom to make small choices in our day-to-day that better the planet before it’s too late. Our hope is that Aqua scales to feed the masses when we need it most.