Algenie Emerges From Stealth to Turn Algae Into Sustainable Fuels & ‘Carbon-Positive’ Plastic

6 Mins Read

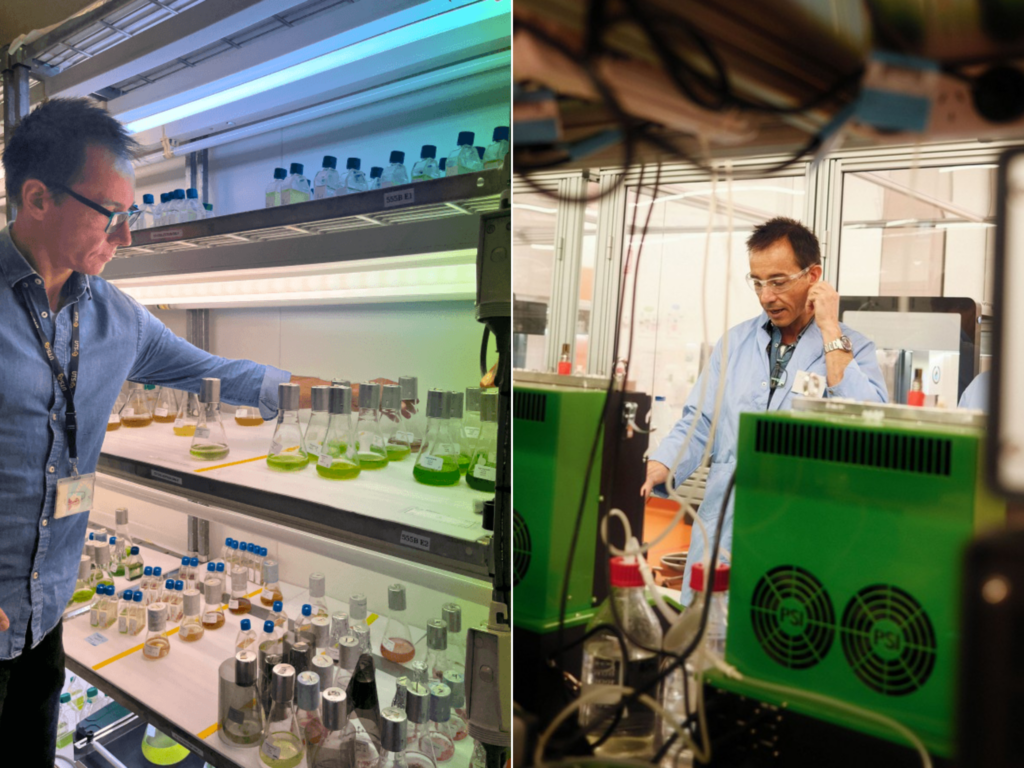

Australian startup Algenie has come out of stealth with early funding for its photobioreactors that can create sustainable fuels, plastics and feed from algae.

Armed with helix-shaped photobioreactors that can dramatically reduce the cost of production, Algenie is a Sydney-based startup innovating with algae to replace planet-harming fossil fuels.

Emerging from stealth today, it has obtained A$1.1M ($730,000) in early funding from Better Bite Ventures, the University of Technology Sydney (UTS), and other investors, aiming to use the capital to build on its initial work of creating “carbon-positive” plastics and biofuels with algae through its next-gen bioreactors.

“Our helix design and technology is a true breakthrough, paving the way for algae-based solutions to become economically competitive with and ultimately replace traditional fossil-fuel-based products,” says founder and CEO Nick Hazell (who previously founded plant-based meat company v2food).

The financing will help Algenie “obtain the clear evidence points” it needs to demonstrate its breakthroughs. “This relates to both the bioreactor performance and construction itself, as well as the biotech tools we are developing with UTS to create the optimal strains of algae and cyanobacteria,” he tells Green Queen.

“We’re not limited to just plastics,” reveals Hazell. “Algae can be used to create everything from food and feed to biofuels and even building materials. The versatility of algae is a result of our ability to engineer different strains to produce specific chemicals and compounds, similar to how yeast is used in various industries.”

Now, Algenie is looking to establish strategic partnerships with clients, and is targeting a “more substantial fundraising round” in the coming months, according to Hazell.

How Algenie’s game-changing bioreactor works

While the sustainability potential of algae is well-known – it absorbs carbon to grow rapidly, and captures more of the gas than any other ingredient or material. Some companies have been making plant proteins from seaweed, others have come out with DHA and EPA supplements, and a few are developing bio-based resins.

Algal cooking oil is also on the market now. But this industry has also witnessed a swathe of closures – from vegan seafood producer New Wave Foods and alt-milk maker Update Foods to biofuel company GreenFuel Technologies – a withdrawal of R&D funding, and shifts away from businesses’ initial focus.

This is because, largely speaking, this micro-plant has been too expensive to produce and difficult to scale up with conventional technology. So how does Algenie manage to overcome this hurdle?

The secret is in the bioreactor system. “The Algenie helical photobioreactor is based around thin-layer algae production, which maximises growth per litre per day,” says Hazell.

“LEDs and sophisticated light management ensure that every microalga gets the photons it needs when it needs them for optimal growth. We also optimise CO2, nutrition, and other variables to maximise the output to levels that are orders of magnitude more than existing systems,” he adds.

Algenie innovates with microalgae and cyanobacteria strains in collaboration with UTS, which works with algae from various collections, including CSIRO’s collection in Tasmania. “We select and optimise each strain according to the product we want to make for the customer we are partnering with. UTS biotech tools enable fast strain selection and optimisation for hundreds of potential applications,” Hazell explains.

Once it identifies a product with a customer, Algenie digs into its database of strains that can deliver the required chemistry, and selects a mutant with high levels of the desired output. “These elite strains are then optimised for high productivity using multiple parallel experiments orchestrated by an AI algorithm,” he says.

“Depending on the use case, the algae will be harvested by the customer and converted into the products that are needed. Our focus is on the lowest-cost biomass and chemistry production, but we will integrate our system into the customer’s downstream processing as needed. Of course, this will be different for a biofuel, a plastic, a protein, or a pigment.”

Enabling highly efficient algae production and low costs

Algenie’s patented bioreactor design allows some algae species to double every two to three hours under ideal conditions. This is enough to produce 100 tonnes per year in the size of a shipping container – the equivalent of manufacturing 2.5 million soft drink bottles. At 10,000 tonnes per year in a hectare-sized field, the startup claims this yield is 3,000 times more efficient than conventional soy or corn crops.

“We use sophisticated sensors and algorithms to optimise the growth of the algae, which is continuously harvested and allows for a 24/7 production system that, in principle, need never stop. Algae systems have run for more than a year continuously, and this is one of the secrets behind our low-cost model,” says Hazell.

Roughly 70cm in width, the helix winds can produce a tonne of algae annually per unit. The design has the potential to bring production costs down by a factor of ten, totalling just $1 per kg of algae.

“Our ability to keep costs so low is a result of a combination of innovative design, efficient manufacturing, and strategic partnerships. Our unique helical photobioreactor design maximises productivity per square metre, while our low-cost manufacturing process can deliver high-output bioreactors at a fraction of current capital costs,” explains Hazell.

“Additionally, our advanced AI and automation systems ensure optimal growth conditions, minimising waste and maximising efficiency. These factors allow us to produce algae biomass at a cost that is competitive with traditional fossil fuels, making algae-derived products a more economically viable option.

“With capital costs lowered considerably, the cost of biomass becomes a function of the cost of renewable energy, which is falling rapidly, especially if we work together with major energy suppliers.”

More work needed to match fossil fuel polymers

Despite the many botched attempts, the algae biofuel market is expected to surpass $15B in value by the end of the decade. The global appetite for bioplastics, meanwhile, could cross $35B by that time. The algae market may be a fraction of the two above, but all these trajectories show that Algenie is in a space that isn’t going anywhere.

Simon Newstead, founding partner at Better Bite Ventures, feels Algenie has “the potential to reinvent algae production” while sequestering carbon at gigaton scales: “We got to know Nick through the APAC food tech ecosystem and believe his visionary leadership and deep technical expertise are perfect for this grand challenge.”

Fossil fuels are the main cause of greenhouse gas emissions, and plastics made from them are responsible for 3.4% of global emissions, a contribution higher than the entire aviation industry.

While Algenie hasn’t conducted a life-cycle assessment yet, preliminary work suggests that the dominant factor in emissions would be the conversion of carbon dioxide to biomass. This is “in the range of 2kg of CO2 to 1kg biomass, i.e., carbon-positive”, says Hazell. “The carbon footprint of the bioreactors themselves will be minor compared to the carbon-positive output of the algae produced,” he adds.

Plastic may take up to 500 years to decompose, but it’s popular because it’s useful. How does Algenie’s alternative compare in terms of durability and quality? “While there has been research into PHA and other bioplastics spanning many decades, there is more to be done to match every application currently met by fossil-fuel-derived polymers,” says Hazell.

“But if the cost structure and environmental impact are favourable, we believe that the industry will be incentivised to drive this. Biofuel research is also quite advanced through decades of research elsewhere, and the problem we are solving is cost and scalability,” he adds.

With applications spanning not just fuels and plastics, but also textiles and fish feed, Algenie is also planning to licence its technology and collaborate with partners to co-invest in large-scale production infrastructure.