Dairy Industry’s Biggest Byproduct Can Offer Low-Carbon Alternative to Meat

4 Mins Read

Whey is the dairy industry’s largest byproduct – but it has enormous potential to reduce food waste and develop sustainable microbial proteins.

Thousands of swimming pools’ worth of whey are discarded every year, polluting aquatic ecosystems and wasting a highly nutritious ingredient.

Now, scientists at the Tecnológico de Monterrey, in collaboration with the Technical University of Denmark (DTU), have developed a process that can upcycle whey into sustainable single-cell proteins through fermentation, presenting a lower-carbon alternative to livestock-derived proteins and a potential food security boost.

“The production of alternative proteins is no longer an option, but a necessity,” said Mario Antonio Torres-Acosta, the project’s lead, who holds a PhD in biotechnology from Tecnológico de Monterrey. “We are facing an unprecedented climate and food security crisis, and developing sustainable protein sources will be key to feeding a growing population.”

Leveraging a non-GMO process key to scientists’ effort

The project is aimed at cutting food waste via circular economy strategies, implementing food safety and traceability systems to ensure quality, and researching accessible and balanced nutrition for vulnerable populations.

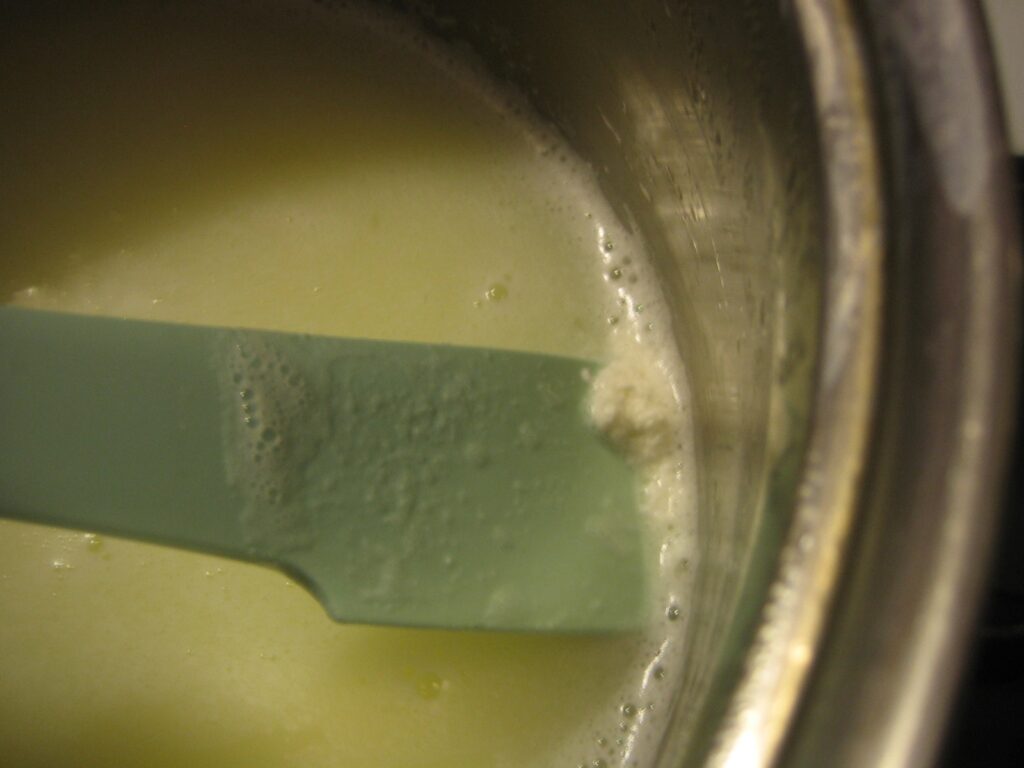

Torres-Acosta and his colleagues converted the dairy industry byproduct into proteins through an innovative precision fermentation process. The effort relies on mixed microbial communities or strategic combinations of microorganisms (particularly yeasts and bacteria of industrial relevance) that can work together to break down the lactose in whey and transform it into a protein-rich biomass.

One of the major goals of the project was to eschew the need for any genetically modified organisms, which the scientists said would facilitate the protein’s market acceptance and scalability. Combining yeasts and bacteria in a controlled ecosystem, they explained, would help maximise protein production without altering the natural composition of the microbes involved.

The resulting protein is rich in essential amino acids and can be highly digestible, with a biological value comparable to that of meat and milk. Its production, meanwhile, generates fewer emissions and requires much less land than livestock farming.

Additionally, the whey-derived single-cell protein can be produced for $1,600 per tonne, with a market price ranging from $5,000 to $7,000 per tonne. For context, beef prices reached nearly $5,400 in the EU last week.

The scientists further argued that proteins derived from microalgae tend to have a strong flavour and an unappealing colour, unlike single-cell yeast proteins, which have a more neutral sensory profile. This makes the latter more adaptable to a wide range of food applications

“The use of microbial communities is key in this process. In nature, microorganisms do not function in isolation but in consortia, where they complement each other. We leverage this principle to optimise the conversion of waste into a product with high added value,” said Torres-Acosta.

Why whey should not be wasted

According to the team behind the project, this technology could be “easily implemented” in regions where cheese production generates large volumes of residual whey.

Around 80-90% of milk that enters cheese manufacturing facilities ends up as whey. Globally, between 180 and 190 million tonnes of whey are produced annually, making it the largest byproduct of the dairy sector by volume.

While about half of this waste is processed into added-value products like whey protein, functional foods, edible films and coatings, and lactic acid, a significant amount is left unused. Whey disposal, however, is a costly process, both in terms of economics and the environment.

Its biochemical and chemical oxygen demands are significantly higher than wastewater, and it can contaminate groundwater and pose risks to farmland if not disposed of properly. In fact, up to 47% of the whey produced by the cheese industry is discharged into water bodies, causing pollution, ecological imbalances, and uncontrolled microbial growth due to nutrient excess. This can lead to phenomena like eutrophication, reducing the oxygen available in the water and affecting aquatic life.

It’s what drives the Tecnológico de Monterrey effort, part of its Flagship Project on Food Security and Nutrition, which seeks to mitigate food security through solutions from sustainable agriculture to the transformation, processing, distribution, storage, and consumption of food products.

“The combination of biotechnology, computational modelling, and precision fermentation allows us to design an efficient, scalable, and economically viable process for single-cell protein production,” said Alberto Santos Delgado, informatics director at DTU’s Novo Nordisk Foundation Center for Biosustainability.

Also in Europe, the German government recently awarded a $2.8M grant to the Hamburg University of Technology and local food tech startup Infinite Roots to develop technology that can upcycle whey into a feedstock for mycelium fermentation.