5 Mins Read

Dutch cultivated pork pioneer Meatable broadens its horizons beyond food through a partnership with animal-free leather maker Pelagen.

As it awaits the go-ahead from regulators in Singapore, cultivated meat startup Meatable already has its eyes on the future.

With cultivated meat facing a squeeze from investors and policymakers in certain geographies, the Dutch startup is expanding its operations to make an impact beyond just the food industry.

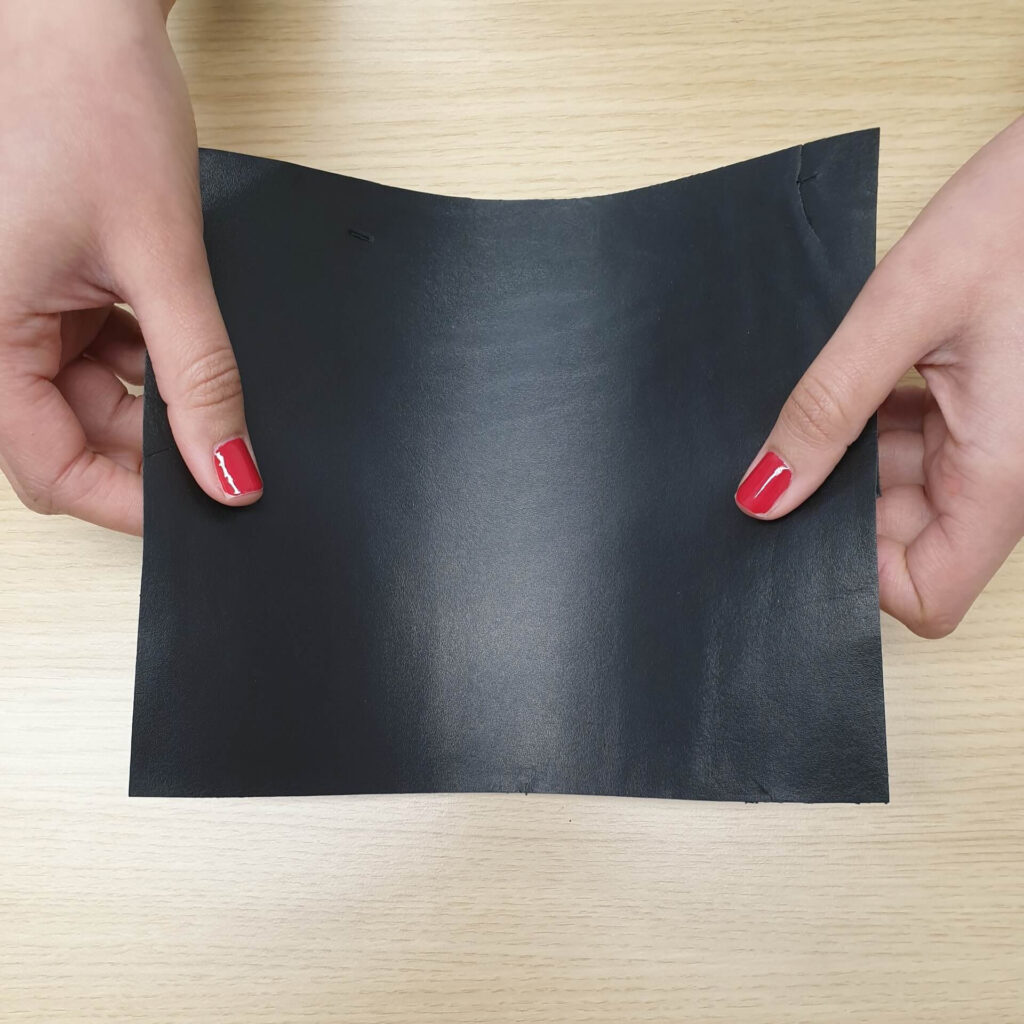

Meatable has partnered with fellow Leiden-based firm Pelagen, which specialises in cell-based leather, to help enhance the production, efficiency and scalability of the animal-free material for use in a variety of industries, including fashion, automotive, and interiors.

“Just as Meatable is revolutionising the way we produce and consume meat, Pelagen is redefining leather manufacturing with a sustainable approach. We’re excited to support their vision and market potential through our technology,” said Meatable CEO Jeff Tripician.

How Meatable’s Opti-ox technology can advance cultivated leather

The collaboration is built upon the Opti-ox technology Meatable uses to produce its cultivated pork sausages. Pelagen will leverage the platform to improve the production of skin tissue from animal cells for its sustainable leather.

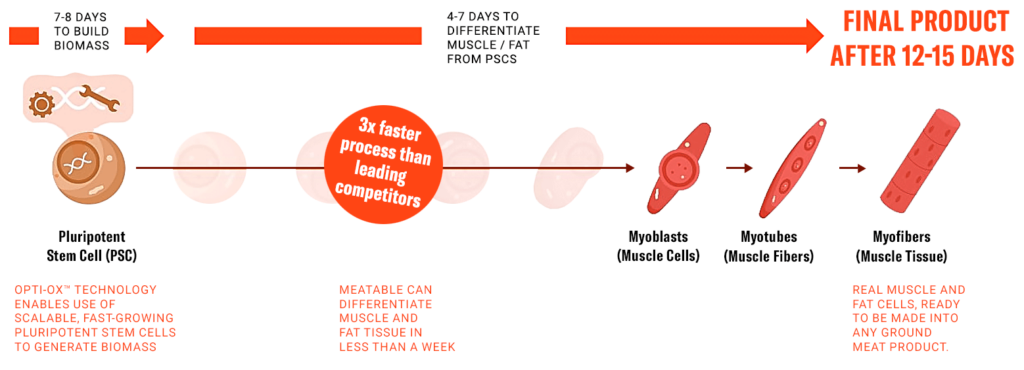

Opti-ox does away with the need for fetal bovine serum and allows Meatable to make products by isolating a single animal cell. The process uses pluripotent stem cells (PSCs), which – unlike immortalised cell lines that need to be altered to multiply indefinitely – have the natural ability to continue multiplying, and do so rapidly.

This is coupled with a perfusion process that allows the startup to work in a continuous cycle to generate very high cell densities and produce fully differentiated muscle and fat cells faster than any competitor. The technology can do in 12 days what it takes a pig eight months to, and a cow two to three years – and was named one of Time Magazine’s Best Inventions of 2024.

“Meatable has demonstrated clear leadership in their field, with a singular capability to enable lightspeed bioprocess,” said Pelagen CEO Sasha Madhavji. “We are excited to leverage their technical edge and accelerate our time to impact – something only possible at commercially relevant scales.”

And unlike traditional synthetic leather, which mainly uses petroleum-derived plastic and can take up to 500 years to break down, a cell-based version dramatically lowers greenhouse gas emissions and waste. Cultivated leather also avoids the shedding of microplastics that can destroy marine life and our waterways, while replicating the look, feel and smell of its conventional counterpart.

To get cultivated leather to market, producers require optimised media and processes too. To that end, Pelagen and Meatable will also endeavour to generate the most effective media composition and process. This will help them lower costs, enhance speed and efficiency, and increase the quality of the animal-free leather.

Can cultivated leather meet the demand for greener products?

Advocates of leather have long viewed it as a byproduct of meat and dairy production and used that to tout its biodegradability and longevity. Leather critics counter that it should more accurately be viewed as a co-product; in many cases, it is the primary product, and manufacturing it is an energy– and water-intensive process linked to deforestation and biodiversity loss.

There is, of course, the animal welfare aspect, given that the material is derived from cows, which drives vegan consumers to look for other options. But leather production also has a much higher carbon footprint, at 110kg of CO2e per square metre, compared to synthetic and plant-based alternatives. Moreover, animal-derived leather releases lots of health-harming chemicals during tanning.

A 20,000-person global survey last year revealed that 85% of people are experiencing disruptive climate change effects, and 46% are buying more sustainable products to reduce their personal impact. In fact, 80% are happy to pay more for them for greener products, with an average price premium of 9.7%.

This will be music to the ears of companies like Pelagen, whose products will likely enter the market with a premium markup. This latest news illustrates the significant potential for companies working on cell-based leather, a market that is set to grow by 14% annually to reach nearly $400M in 2032.

Take Parisian startup Faircraft, for example, which recently secured $16M from investors and is working with local leather artisans and fashion brands. In the UK, Lab-Grown Leather Ltd and 3D Bio-Tissues are advancing this material, while Singapore’s ProjectEx is working on cultivating exotic leather alternatives to crocodile and ostrich, for example.

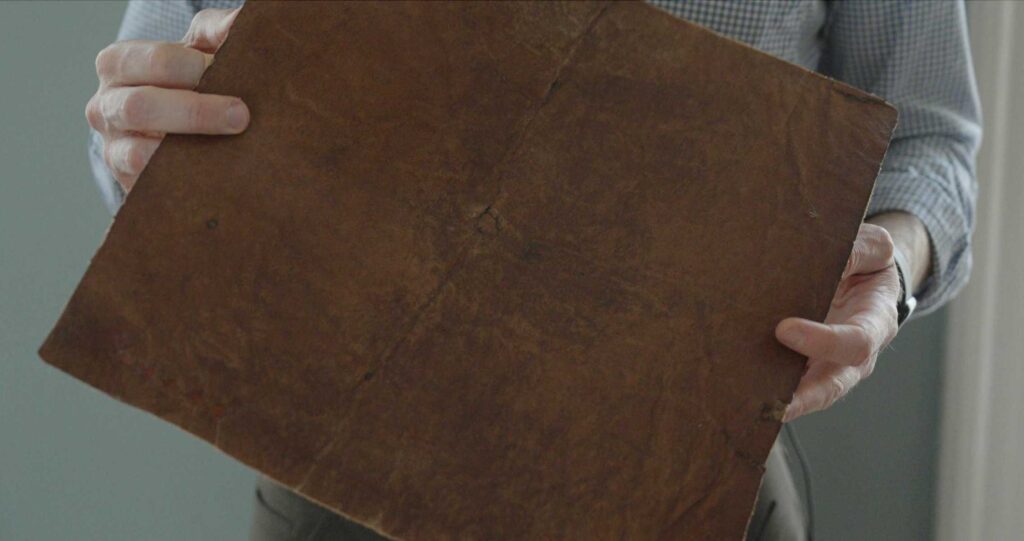

Qorium – another Dutch player – is led by Mosa Meat founder and cultivated meat pioneer Dr Mark Post, and recently produced a 35x35cm sample of cultivated leather using a newly scaled-up tissue bioreactor.

In the US, Uncaged Innovations is making a grain-based, plastic-free leather alternative, and has been in discussions with several luxury brands. Modern Meadow – which was previously working on cultivated leather – is showcasing its Bio-Vera lineup (made from 80% renewable carbon content that includes plant-based proteins and upcycled tires) at the Lineapelle 2025 show in Milan later this month. And Ecovative is using mycelium to make its eco leather.

Another 3D tissue engineering startup, US-based VitroLabs, caught the attention (and financial backing) of French luxury giant Kering and actor Leonardo DiCaprio in its $46M Series A round in 2022 – but its cultivated leather failed to take off, and the startup appears to have ceased operations last year.