How Mushrooms Can Turn Food Waste Into Proteins, Vitamins & Packaging

4 Mins Read

An EU-funded research project is exploring how supermarket mushrooms and agricultural waste can be turned into proteins, vitamins and bio-based materials.

Combining mushrooms, food waste, fermentation and artificial intelligence can deliver alternative proteins and biomaterials fit for the future, according to researchers at the Danish Technological Institute (DTI).

The research centre is leading a four-year project called Zest, which has a budget of nearly €7.5M and is co-financed by the public-private Circular Bio-Based Europe programme. It aims to develop a fungi-based fermentation system to produce bio-based products like proteins, nutrients, nutraceuticals, cosmetics, and packaging.

“The result is a more sustainable and cost-effective method for protein production, which at the same time has a high level of food safety,” explains DTI director Anne Christine Hastrup.

Sidestream valorisation cuts both waste and costs

The project focuses on optimising fermentation processes and utilising low-cost agricultural waste streams as feedstock to produce upcycled mycoprotein for a variety of applications.

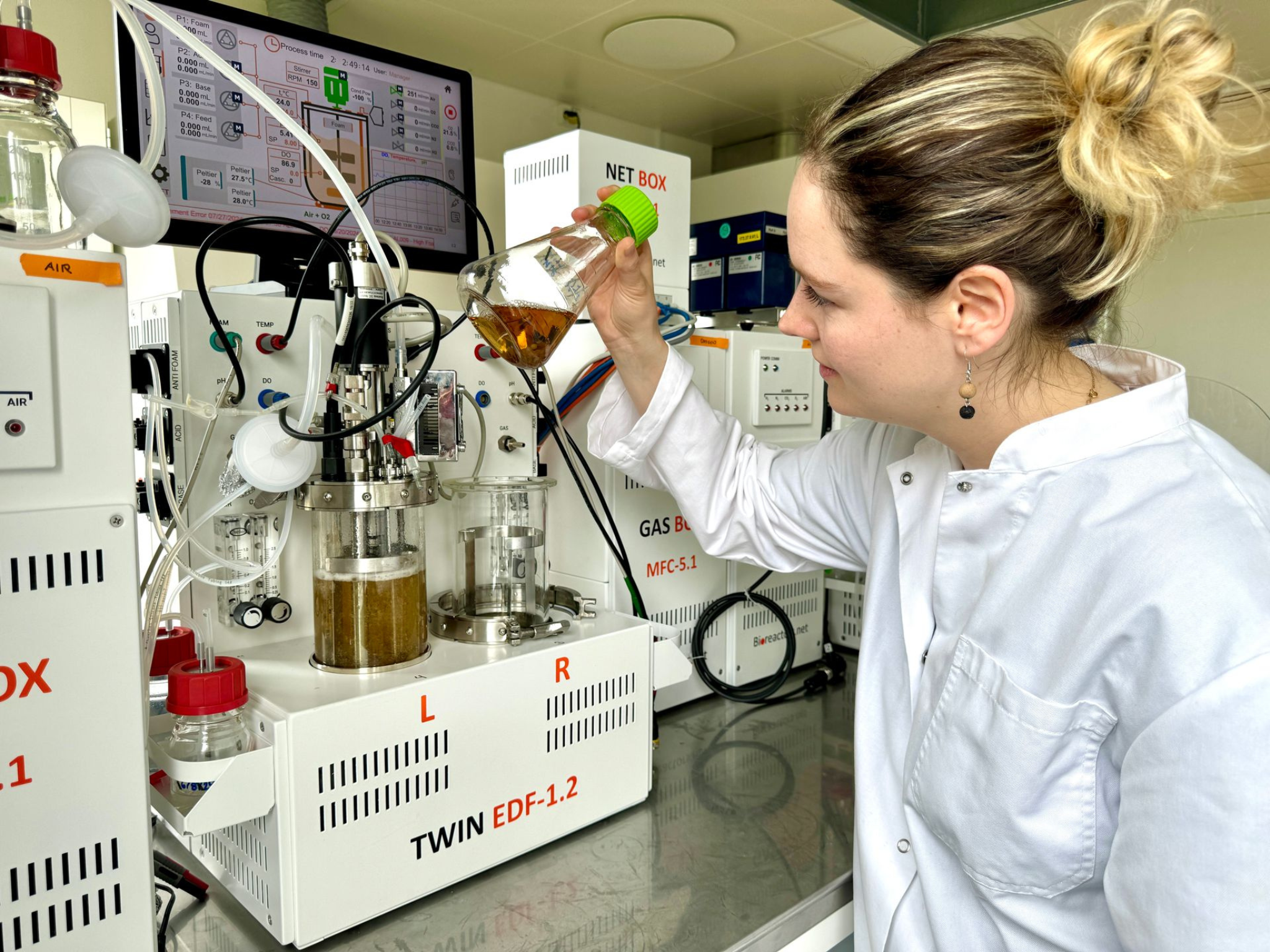

The researchers are taking edible mushrooms that you can find in supermarkets, and feeding them on farm byproducts like residues from sugar beet production, spent brewer’s grain from beer manufacturing, and fruit peels. These sidestreams are pre-treated before the fermentation process in bioreactors, where the fungi convert them into biomass.

“You can compare it to kombucha brewing, where you feed a fungal bacterial culture with sugar. In the EU project Zest, the culture consists of mushroom strains that convert agricultural residues into biomass, which we can use directly or extract mushroom protein and chitin from, which are used in medicine, food and bioplastics,” says Xiaoru Hou, senior project manager at DTI.

The resulting products can range from edible proteins and vitamins to bio-based materials and packaging, outcomes that startups can test and develop at DTI’s Biosolutions Technology Center.

The researchers claim the production method contributes to a zero-waste and circular economy, since the mushrooms are fed with agricultural residues that would otherwise go to waste. Valorising the sidestream additionally allows fermentation companies to reduce their media costs, lowering the final price for consumers too.

“At the same time, the process only requires small amounts of water compared to more traditional protein production, while the emission of greenhouse gases is also significantly lower,” says Hastrup.

Plus, DTI suggests that mycoprotein is easier to digest than plant protein, and is a source of vitamins B12 and D. It also has a neutral flavour profile due to its cell structure and different textures, which would help address the taste and texture demands of consumers.

Harnessing AI to optimise mushroom fermentation

Hastrup says DTI is specially designing new bioreactors for mushroom fermentation. “We will optimise the entire production process by screening the most suitable waste products from agriculture and food production together with different strains of fungi.”

This is a key objective of the EU-backed project, which is hoping to improve product quality through post-processing techniques, evaluate the functionality of extracted ingredients in food and pet food prototypes, and monitor waste production and energy use to meet sustainability goals.

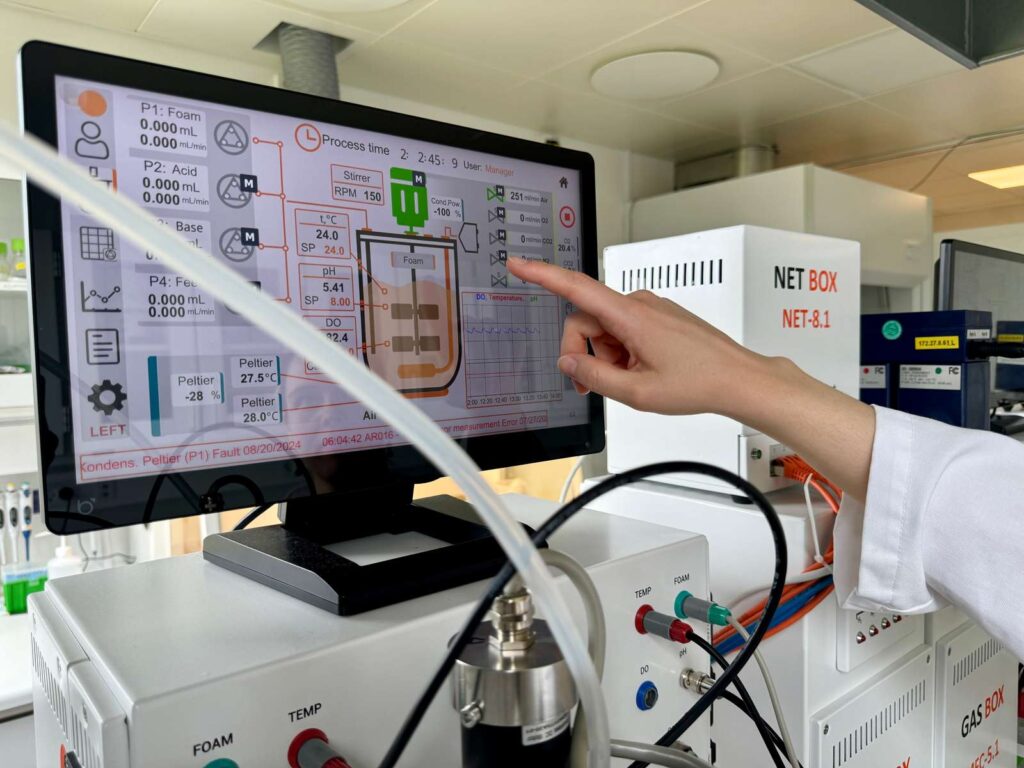

The researchers are also creating an AI-based machine learning model to predict fermentation outcomes, using data from sensors in the bioreactors to implement control systems to correct parameters automatically, and monitor and adjust mycelium production conditions for optimal yield and quality.

“In the Zest project, we develop machine learning models based on parameters such as temperature, pH, oxygen levels and nutrient concentrations,” explains DTI’s Kristian Damlund Gregersen.

“We use hybrid models that combine traditional models of fungal growth with AI models trained on experimental data. The models can predict how the fungi behave on different agricultural residues and help fine-tune the bioreactor for optimal growth conditions,” he adds.

The AI-led approach further allows for a more sustainable production process, according to the researchers. The large database and ongoing adjustments allow them to optimise the yield, reduce waste, minimise energy consumption, and ensure high quality for the end products.

AI is becoming an increasingly popular tool for researchers and startups in the alternative protein space. The technology plays a central role in Bezos Earth Fund‘s $100M commitment towards three research hubs, while Shiru has an AI-powered platform to discover proteins and ingredients. And startups like Climax Foods, NotCo and Howw Foods employ AI to inform the development of their meat, dairy and egg alternatives.