4 Mins Read

Revo Foods has opened what it says is the world’s largest factory dedicated to 3D-printed food, rolling out an updated whole-cut mycelium salmon fillet as the facility’s first product.

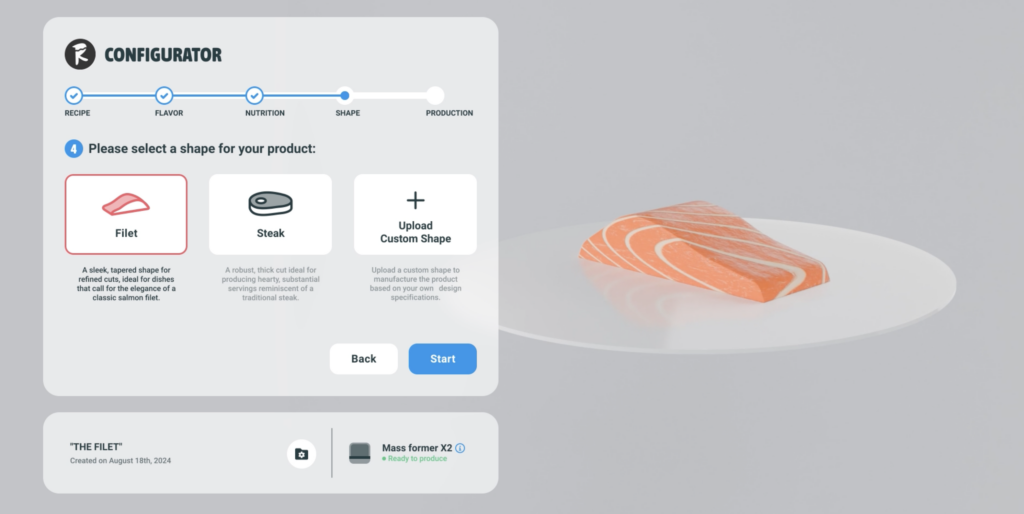

Austrian alternative protein startup Revo Foods has unveiled a new production facility and an updated version of its flagship 3D-printed salmon.

The new site, dubbed the Taste Factory, can produce up to 60 tonnes of product a month at full capacity, and is described as the first manufacturing plant to apply 3D food-printing technology on such a scale.

It makes use of Revo Foods’s 3D Structuring tech, which combines two materials (like fat and protein) into complex new forms, in this case resembling meat muscle structures. It helps create desirable textures and juicy, tender structures that are key for vegan fillets. The fat integration creates the delicate layers of its salmon analogue, which are said to separate when baked or fried.

“With 3D Structuring, we can create entirely new textures using simple but nutrient-rich ingredients like mycelium, creating products that are just so much more exciting,” said Revo Foods CEO Robin Simsa.

Marrying mycelium with 3D printing

Revo Foods, founded in 2021, introduced the first iteration of its mycoprotein-based salmon just over a year ago, initially rolling the whole-muscle seafood analogue at Rewe Group’s vegan flagship store, Billa Pflanzilla.

This was born out of a collaboration with Swedish mycoprotein company Mycorena, which has since filed for bankruptcy and been acquired by another fermentation firm, Naplasol. “Mycorena was doing amazing work, but thankfully, we found a way to not be affected by the bankruptcy,” Simsa told Green Queen. “Nevertheless, I hope their great work will live on.”

Now, it has updated its flagship salmon SKU, called The Filet – Inspired By Salmon, which has a Nutri-Score rating of A, and contains omega-3 (from microalgae oil), as well as vitamins B6, B9, and B12. It’s also high in fibre, and has more protein than its predecessor (14g vs 9g per 100g). The product will first roll out at over 500 Rewe stores in Austria.

Mycelium – the root-like structure of filamentous fungi – is becoming an increasingly popular base for meat analogues, with companies like Meati, The Better Meat Co, MyForest Foods, Prime Roots and Infinite Roots all banking on the nutritional, environmental and functional advantages of the ingredient. Mycoprotein, the protein derived from mycelium, first became famous with meat-free giant Quorn.

“Biomasses like fermented mycelium are trending because their natural consistency requires little processing and they are very nutrient-dense,” said Niccolo Galizzi, head of food tech at Revo Foods. “However, in its pure form, it often tastes bland. We believe that for real change, sustainability and culinary pleasure must go hand in hand.”

He added: “We are already working on the next innovations with mycoprotein, which is a lot of fun using 3D Structuring technology since it offers many possibilities to design the product exactly to the liking of consumers. We like to focus on taste and nutrition, but also on what makes the culinary experiences so unique: getting the texture and authentic mouthfeel right.”

New revenue stream and mushroom fillet on the cards

The new Taste Factory will allow Revo Foods to scale up its operations, and potentially open up a new revenue stream as well. While the startup is currently operating the factory in two shifts just to meet demand, Simsa said it is open to manufacturing partnerships with other companies.

“In the future, we want to focus more on being a technology provider – a provider of process equipment to other food players,” he explained. “We have observed that our technology is of interest to companies outside of the traditional plant-based industry – think dough-like ingredients. We are currently exploring the feasibility of projects.”

He added: “Apart from this, we have collaborative projects with a number of companies interested in meat alternatives with distinct shapes/structures.” He hinted at an announcement about these partnerships in Q1 2025.

These companies may be attracted by the fact that Revo Foods’s technology doesn’t need the high temperatures or pressure traditionally seen in industrial production methods, which lowers the nutritional value of the product. Instead, the startup operates under milder conditions that retain micronutrients.

“The production is most efficient at scale. We are still optimising parts of the process to make it most efficient, implement more automated steps and increase the amount of output per machine,” Simsa said. “Also, we’re improving the software controls for the kinematic system.

“Overall, we see the Taste Factory as a showcase for what this technology can do, and The Filet as the ideal proof. We also need it to improve the actual production setup.”

Having raised €7.5M ($8.3M) in investment so far, Revo Foods is continuing its efforts to fundraise as it explores new products. One of these could be what Simsa termed a “more natural mushroom protein fillet”, one that would have “an exciting new texture” and umami flavour without attempting to mimic meat – much like what Fable Foods is doing.

“Many people tell us that they want a good protein-rich meal but not necessarily something with a meat-like taste, which is why this is an interesting avenue to explore,” he said, before confirming that the company will soon relaunch its vegan octopus SKU, called The Kraken.