LanzaTech Expands Gas Fermentation Tech to Recycle Waste Carbon Into Protein, Partners with US Military

6 Mins Read

Synbio firm LanzaTech has extended its carbon recycling operations to human food applications with a new protein, and teamed up with the US military on a joint project.

A company that turns waste carbon emissions into high-value products is making a move for the human food market with a nutritionally complete protein.

Chicago-based LanzaTech, a pioneer in the carbon recycling space, is expanding its biorefining platform to produce microbial protein from gas fermentation, in a bid to address the climate, supply chain and food security challenges presented by animal-derived proteins.

Dubbed LanzaTech Nutritional Protein (LNP), the ingredient can be used in foods such as non-dairy cheese, meat analogues, breads and smoothies, and extend to non-human applications like pet food, as well as animal and fish feed.

To further its efforts, the company has partnered with the US Navy Research Lab on a project co-funded by the Department of Defense to explore protein production on its ships and meet the nutritional needs of soldiers and sailors across the armed forces.

LanzaTech, which went public via a SPAC merger in 2022, has built upon its existing technology that ferments carbon-rich waste streams to produce ethanol as a primary product. The leftover bacteria can be freeze-dried to form a protein-rich biomass, and has already been sold for animal feed applications.

But the company has now adapted its microbes and process to directly produce LNP as the primary product, allowing it to diversify its product range and revenue streams, optimise its value creation, and reach a larger number of consumers.

“This is a natural extension of our platform, and we have been working on protein for a number of years, including before we went public,” says CSO Zara Summers, who reveals that LanzaTech has already sold 25,000 tonnes of single-cell protein from its operations as animal feed.

“We decided to enter the protein market because we have always had a firm belief that recycled carbon could impact every aspect of our lives and provide new pathways to the products we use every day, including food,” she tells Green Queen.

Several facilities lined up in the coming years

LanzaTech is leveraging Cupriavidus necator – a soil bacterium – to produce LNP, and using feedstocks similar to its current operations, which have spawned commercial-scale volumes of ethanol for apparel, packaging, surfactants, and sustainable aviation fuels.

“We have a process that consists of continuous fermentation in a gas fermentation reactor, where biomass can be continuously drawn into a deactivation, dewatering, and spray dry workflow,” explains Summers.

“LanzaTech was founded to find alternative pathways that could avoid impacting land, water and biodiversity, and, importantly, keep fossil resources in the ground,” she adds. “As we came to understand the biological make-up of our commercial production strain and adjacent applications for our commercial bioreactors, we saw a natural evolution in our technology platform go beyond producing a protein co-product to make a dedicated nutritional protein product with a new microbe.”

The company’s CEO, Jennifer Holmgren, says that it has developed a path to mass-producing protein from CO2 by “coupling a new microbial production strain with our existing bioreactor technology”.

LanzaTech has been operating a pilot facility in Skokie, Illinois for the last two years, producing two to three grams of protein daily as it prepared for commercialisation. “In the process, we’ve partnered with leading brands and food testing organisations for rigorous analysis and prototyping of nutrition applications,” says Holmgren.

Now, the company is in the engineering design phase for its first pre-commercial facilities, slated to open in 2026 in collaboration with several partners, with a capacity of between 0.5 to one tonne of protein per day. LanzaTech has additionally developed a roadmap to commercial-scale production in 2028, which would see it manufacture over 30,000 tonnes of LNP per year in larger facilities.

The multi-pronged benefits of LanzaTech Nutritional Protein

Scaling up will help LanzaTech make its gas protein cost-competitive with animal proteins, which is crucial for a resilient food supply amid a fast-growing global population.

Aside from the fact that it recycles carbon emissions from the atmosphere to make food, LNP also uses a fraction of the land and water that conventional protein sources need, while having no negative impact on biodiversity.

Plus, there’s the nutritional prowess. “LNP is 80% protein by dry weight and is complete with all amino acids,” says Summers. “Its functional properties are similar to those of whey and pea protein. It is odourless and neutral in colour, which makes it ideal for formulating.”

According to the company’s calculations, its facilities’ 0.5-tonne capacity combined with the ingredient’s high protein content is the equivalent of the typical complete daily intake of protein of around 9,000 people.

LanzaTech has no plans to make its own products from the protein, instead supplying it to other companies for various applications, including human nutrition, pet food, and animal feed.

“For human nutrition, this protein’s characteristics make it ideal for formulation, and we have already tested its properties and formulatability with food innovator Mattson,” Summers says. “As part of Mattson’s characterisation work, they prototyped the protein in baked goods, protein bars, smoothies, dairy-free cheese, and more.”

She adds: “With the Center for Aquaculture Technologies, we successfully completed salmon and shrimp feed trials. We are currently conducting feed trials for pigs and poultry, as well as pet food testing with a leading pet food brand.”

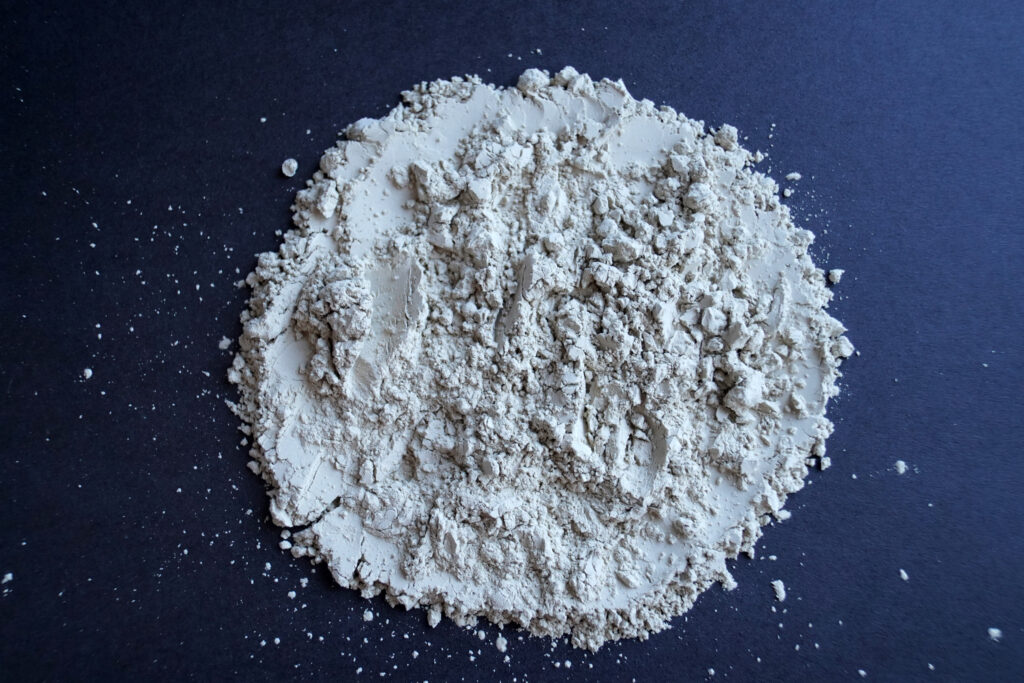

LNP is supplied in the form of a powder that requires minimal downstream processing. “It can be used as a protein-rich powder that could be used as a flour, or used as any protein powder is used today (like whey, pea, or soy powders),” says Summers.

LanzaTech locks arms with the US military

LanzaTech is in the middle of completing trials for animal feed (including pet food), and is also finalising its human food dossier for the FDA to achieve self-determined Generally Recognized as Safe (GRAS) status in the US.

To advance LNP’s progress, it is evaluating “several financing structures” for the development of its first pre-commercial facility. “We recently raised $40M through an investment by Carbon Direct Capital, who is a globally recognised investor in the carbon management ecosystem,” says Summers. “This investment is to fund ongoing operations for LanzaTech as a whole, of which LNP is a part.”

In addition to its partnerships with food producers, it is working on a joint research and contract development project with the US Navy Research Lab, which is funded by the Office of the Under Secretary of Defense for Research and Engineering, the Office of Naval Research, and the US Naval Research Laboratory (NRL).

The aim is to work out if LNP can be produced on military platforms. “Together, we are exploring the biomanufacturing potential of a nutritional protein product made from CO2 extracted from seawater,” says Matthew Yates, a research biologist at the NRL.

“Integrating LanzaTech’s state-of-the-art gas fermentation technology with the US Naval Research Laboratory’s Seawater Carbon Capture Process presents a valuable opportunity to develop a unique capability to meet the nutritional needs of soldiers and sailors across the joint forces, while simultaneously enhancing the resilience of military operations in an evolving geopolitical landscape,” he added.

The Department of Defense, which the research and engineering office falls under, recently drew fire from sections of conservative media, Republican Congress members, and livestock lobby groups for opening funding proposals to develop cultivated meat for the military. Following the criticism, the DoD revoked its call.

But Summers says LanzaTech isn’t concerned about any backlash from its military partnership: “We have many projects that have applications with the military at this time, from on-demand protein production in theatre, to humanitarian relief, to creating domestic supply chains that can meet any need that our country requires by leveraging abundant waste resources.”