12 Mins Read

Project Eaden co-founder Jan Wilmking on why fibre-spinning technology can solve plant-based meat’s woes, the startup’s investment plans, and when it will come to market.

On the German morning show ZDF Morgenmagazin in 2017, Jamie Oliver declared Jörg Förstera, owner of Berlin butchery Kumpel & Keule, the best butcher in the country.

It was a stamp that echoed what many in the public felt as well. Kumpel & Keule prides itself on quality, noting that “only the best belongs in a good sausage”.

So when someone like Förstera endorses a plant-based meat product, it’s worth paying attention. After all, the only way animal-free meat producers will have an impact is by appealing to meat-eaters – and the people who sell and cook it for them.

“For me, the meats from Project Eaden are the first alternatives that get extremely close to the taste profile of animal meat,” says Förstera. “Really impressive.”

The German startup – founded in 2022 by Dr David Schmelzeisen, Hubertus Bessau, and Jan Wilmking – first made global headlines last year, when it came out of stealth to announce an oversubscribed €10.1M seed round, featuring EU food and climate VC stalwarts including Creandum, Magnetic, Food Labs, Shio Capital and Mudcake.

Food tech social media was filled with photos of what is considered to be the holy grail of plant-based meat: whole-cut steak. The image of the company’s steak fillet (see below) made the rounds online, where commentators wondered if the photo was doctored. It was not.

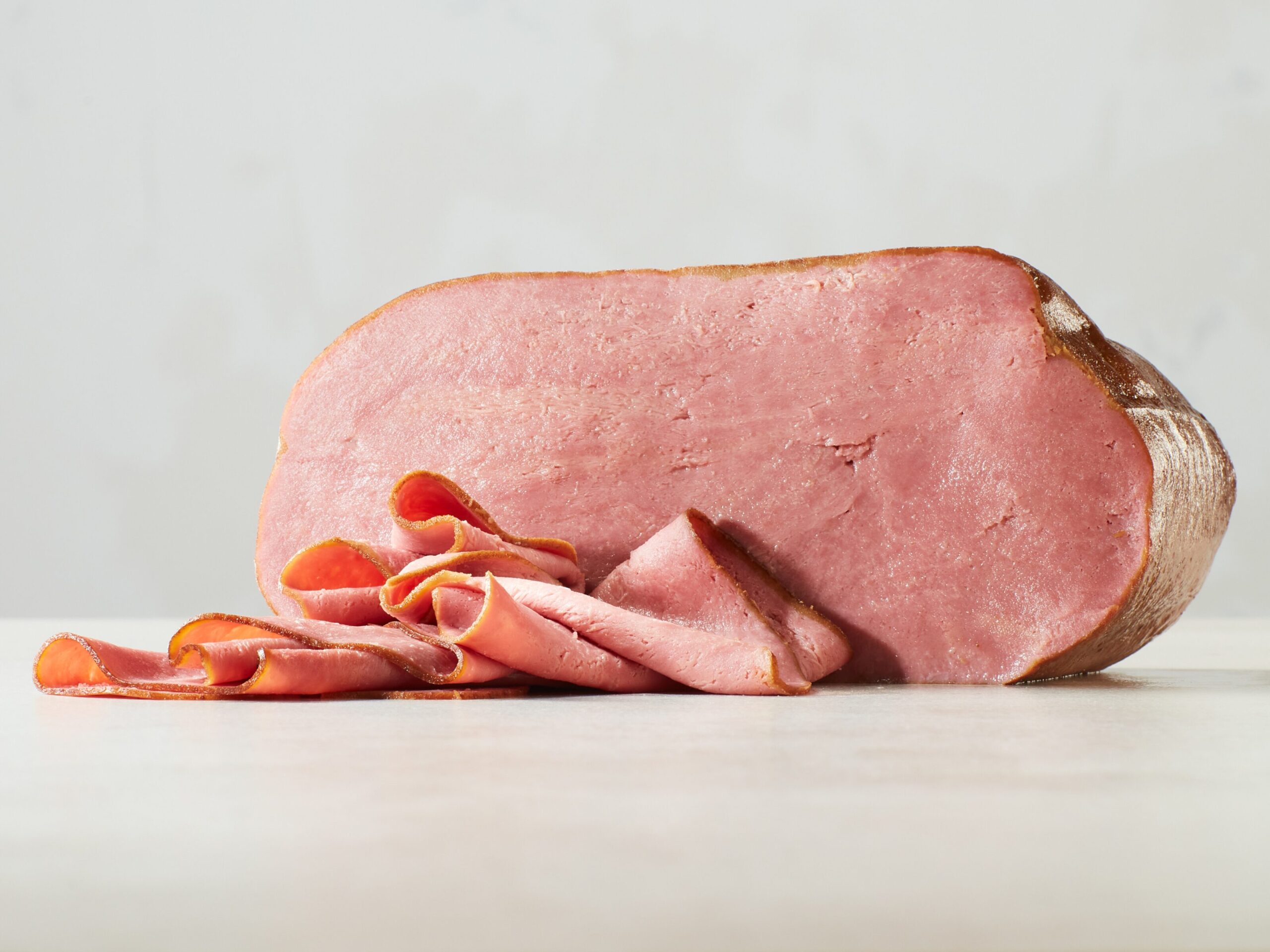

In less than two years, the company has successfully used its technology to create a wide range of whole cuts including sausages, pork loin, and beef steaks, “a full meat range for everyday life” as the company puts it. But also, ham.

Ham: the other plant-based holy grail

As with steak, ham and deli meats are for some another holy grail of the meat alternative market, particularly for Europeans. Until recently, there have been almost no contenders for true ham lovers.

Last year, French plant-based meat startup La Vie debuted two cooked ham products (emulsified soy) to well-deserved fanfare and a small handful of US startups like Prime Roots (fermented koji base) and Unreal Deli offer American-style deli cuts but, unlike plant-based burgers and chicken nuggets, there is plenty of room for a new player like Project Eaden to disrupt the ham case.

For meat-eaters, taste and texture remain a major stumbling block when it comes to whole-cut meat analogues. Project Eaden says it is solving for both. The company says its tech results in “realistic optics and a realistic, heterogeneous chew experience.”

Fibre-spun meat attracts industry veterans

So what makes Project Eaden’s meats “really impressive” to people like Förstera? To make the novel food, the startup leverages ancient textile technology. In Egypt, spindles were used to turn flax fibre into yarn. In 1665, the idea of producing synthetic threads through the spinning wheel was first floated. It was the 1930s that birthed the first spinning of fully synthetic fibre in the form of nylon and polyester.

Fibre-spinning changed the face of the fashion industry, and Project Eaden hopes to use the same technology to transform the food system.

The fibres produced by Project Eaden’s highly scalable tech can be designed to meet technical requirements like elasticity, water-binding ability and strength. Plant proteins are bundled into strands, and then unfolded in a solution to create a homogenous liquid. This is spun to form ultra-thin fibres, which get integrated into a compound to replicate the collagen-based connective tissues found in animals.

“Our technology essentially uses two main types of fibres to make delicious meat-like products,” explains Wilmking, the company’s managing director. “First, we use strong and thin fibres for connective tissue, which don’t stick together much, but help make the meat structure and bite experience feel real. Then, a large part of our product is made from a cheaper, juicier fibre that sticks together just enough to hold meat juice in small spaces, making it taste tender and yummy, like real meat.”

The technology has excited industry executives like Godo Röben, former managing director of German meat and plant-based giant Rügenwalder Mühle (Wilmking refers to Röben as the godfather of Germany’s plant-based industry). “When I heard about the idea for the first time, I thought: that can work. And I invested early in the seed round at a time when frankly, their prototypes were still very, very rough,” he tells Green Queen.

Röben came on as an advisor to the startup, galvanised by Project Eaden’s “team, tech and traction”. “I could see from early on that retailers, B2B and foodservice clients will want Project Eaden’s products,” he says.

Plant-based meat is a crowded space, but for Röben, this startup stands out because it’s “very fast and very professional at the same time.”

Triple threat: a founding team with commercial experience, tech expertise and food industry knowledge

“The quality bar is really high. The pace is high. And finally, the products deliver taste and texture unseen in the market,” Röben says.

This isn’t the founding team’s first rodeo. Where plenty of food tech startups boast a technical founder, many lack founding teams with operational commercial experience, or a food industry background, Project Eaden’s founders and advisors each bring multiple careers worth of expertise.

After a stint at McKinsey and Harvard, Wilmking cut his teeth working for Rocket Internet’s Zalando, rising to be a senior VP. As anyone who has worked for the famed Samwer brothers knows, there is no better business school than running a Rocket company.

Schmelzeisen, who holds PhD in textile engineering focused on textile welding and production tech for smart textiles, has previously supported research into smart textiles at RWTH Aachen University and developed electronic sensor systems to integrate into textiles at ETH Zurich. Schmelzeisen is also a passionate and experienced hobby chef, which is how he first saw the connection between textile fibres and meat fibres.

Rounding out the team as a founding advisor is Bessau, a German food industry insider, having co-founded cereal startup MyMuesli in 2007 and built it up to a multi-EU-country brand employing over 850 people.

Project Eaden is keeping things affordable

Project Eaden suggests that its meats, however tech-forward, offer a much-needed solution to plant-based’s affordability problems. As the company explains: “Our technology platform is textile tech, which has been optimised for massive scale, low cost and low CAPEX for decades.”

According to Schmelzeisen, wet and rotary spinning processes are usually very expensive and can lead to slick fibres that don’t connect with each other. He says Project Eaden has solved this issue. “We have developed a new way of spinning proteins, which is cheap to run and creates meaty fibres. We still use wet spinning, but only selectively.”

This allows it to keep costs low. “Our tech has the benefit of being cheap to run, and cheap and fast to scale up in terms of equipment,” he says. “Our roots in the world of textile technology and mechanical engineering have paid off, as this angle has unlocked both low capital expenditure and cost of goods, especially low process cost and a high degree of automation.”

Massachusetts-based Tender Foods is another startup making fibre-spun meat analogues, likening its production process to spinning cotton candy. The company has raised a total of $23M since it launched in 2020, closing an $11M Series A round last month led by Rhapsody Venture Partners and Lowercarbon Capital, and it inked a deal with meat-free QSR chain Clover Food Lab to feature its fried chicken and pork as bowl toppings.

How does Project Eaden’s tech differ? Schmelzeisen says that where others are using a single-fibre approach, “we follow a multi-material approach: meat is muscle, and muscle is organic fibre compounds, made of different fibre types.”

The multi-fibre tech allows the team to replicate the mouthfeel of different types of meat that they say has not been achieved to date: “We replicate this logic and combine different fibre types to create the sensations of meat. Muscle fibres, connective tissue, adipose tissue. All made from plants, designed to match mechanical properties of meat fibres.”

To safeguard its IP, the company already has three patents pending, all of which are “focused on fibre spinning and fibre compound creation (i.e. meat creation), covering key aspects of process and end products”.

Project Eaden is developing its own, bespoke flavours

So that’s the texture stuff. But in order to truly capture the market, companies need to address flavour, which has become the most important purchase driver for meat analogues.

For Project Eaden, the USP is “little to no off-taste”, according to Wilmking. “One thing that has a massive impact on flavour is the spinning process, which leads to a significant reduction of undesirable plant taste notes, aka off-taste,” he says.

“So our spinning process, rather than the exact selection of input materials, helps to generate a nearly blank canvas in terms of taste, which we can [project] our flavours on. No need for maskers, no need for massive seasonings.”

He adds that the company has been working with large flavour houses and developing its own reactive flavours, rather than opting for a pre-made blend. “This has really changed the game, and has created deeper, more complex meatiness and more realistic roasting aroma,” Wilmking says. “The combination of a blank flavour canvas with hardly any off-taste – and truly meaty taste notes on top – makes the products extremely tasty, without being too extreme or intense.”

The base ingredient for all its meat products is wheat protein, complemented with fava bean and/or pea protein. “We use blends of proteins depending on fibre and meat type,” he says.

“Generally, wheat protein can be sourced locally in high quality and provides a great base texture. But it is way too elastic on its own. Hence, we blend it with other protein types, which are great at holding water and releasing it when chewed (juicy mouthfeel), or which add brittleness and roughness for a realistic chew.”

Cooked ham will be the first retail product

The technology also allows the startup to create a wide range of cuts, from Serrano and cooked ham, bratwurst, and bacon to chicken breast, pastrami, and beef and pork flank steaks. “From the start, one of our goals has been to build a highly versatile production platform,” he says. “One base process, one set of input materials, a large variety of end products – all created very efficiently in terms of COGS and with low CAPEX.”

He adds: “Today, we can see that it works. The portfolio of possible products ranges from pork and beef to chicken. And we’ve developed products for cold and warm applications on the same fibre tech platform.”

The cooked hams will come to market first. Wilmking explains it’s a product he and Schmelzeisen grew up with as a staple in their fridges. “We tested hams last summer and our early prototypes hit home with the team instantly,” he says. “Since then, we tested it with friends, family, and finally retailers and food service professionals and it got better and better. Now, we feel it’s ready for the ‘real stage’, called retail shelves. And it’s a pretty large market in and by itself, like nearly all segments in the world of meat.”

Project Eaden says its meats can add a fibrous texture to mycelium-based or cultivated versions (the latter being an example of hybrid meat). Would it be tempted to look into the evolving blended meat space (a mix of conventional meat with plant-based or fermented ingredients), which has attracted industry giants like Nestlé and Quorn?

“Slaughtered animal meat integrated with our meat is not on our agenda,” states Wilmking. “What we have explored and continue to do so is to collaborate with lab-grown meat and precision fermentation startups to test [the] integration of their materials into our meat technology.

“We can add texture to their materials, which by nature have no fibrous texture yet. We focus on plant-based now, however, given the ongoing regulatory challenges. So this is a longer-term exploration and initiative for us.”

An increasingly greater hurdle for consumers when it comes to plant-based is health and nutrition. But the numbers for Project Eaden are encouraging. Its cooked ham, for example, has 21g of protein, while the flank steaks boast 28g, both on par or higher than their conventional counterparts. Plus, the plant-based versions contain the all-important fibre, and zero cholesterol.

The company is raising a Series A ahead of a 2025 launch

Unlike many others in the industry, Project Eaden is opting for a retail-first approach and has secured a listing with a leading supermarket chain in the Germany, Austria and Switzerland (DACH) region. The first products are slated for a launch in early 2025.

“It’s the fastest route to market for us. We have listings in DACH and can reach millions of people, with full control over product and brand experience,” says Wilmking. “We believe it creates everyday relevance fast and will open doors for B2B in a later stage.”

He notes that the feedback from retailers has been “very positive”: “The meatiness and real-like look and taste are really interesting across products, which is why they are not only interested in one product but a range from the start.”

As he alluded to, Project Eaden will enter B2B eventually. “One super interesting channel could be to feature our products as ingredients in convenience meals, which also touch the lives of many people every day, especially those of busy professionals and families,” he says. “From frozen ready meals to frozen pizza, meat is still a massive part of them and we see a big opportunity for partnerships.”

So far, the company has secured more than €12M in funding, with an additional €2M in public grants to add to their seed last year. “We are currently raising a Series A to scale up and service retail demand,” reveals Wilmking.

Raising capital is tough work in the current VC environment. Financing for plant-based companies fell by 24% in 2023, reaching $908M. And in the first quarter of 2024, the sector attracted just $58M. That coincided with faltering sales in some markets.

“There are only [a] few products consumers really love. It’s a ‘bestseller’ market rather than an even distribution of success,” suggests Röben. “I believe there is a lot of room to consolidate the current offer and substitute ‘so-so products’ with really good ones.”

He continues: “That’s good for consumers because overall quality and value for money will improve, and it’s good for retailers because repeat buys and rotation in the plant-based alternative shelves will increase.”

While some decry the plant-based market stagnation in geographies like the US, in Germany, the ecosystem is thriving, according to Röben, who tells Green Queen the vegan market has actually grown in the DACH region. In Germany alone, plant-based meat production was up by 17% last year, according to federal data. “The little slowdown we saw after the pandemic is over,” he says. “The market is hungry for better products that finally hold what they promise.”

As early as next year, then, you could be eating ham made the same as the clothes you’re wearing.