French Animal-Free Dairy Startup Bon Vivant Raises €15M Seed Round for B2B Whey Protein Ingredient

5 Mins Read

French precision fermentation company Bon Vivant, which is working on animal-free whey and casein proteins for dairy, has closed an oversubscribed €15M ($15.9M) seed round. The startup’s new manufacturing facility will open by Q2 next year, and it is expecting FDA approval for its beta-lactoglobulin by 2025.

The cash injection takes Bon Vivant’s total investment to €19M ($20.1M). The company, which aims to develop animal-free whey and casein proteins via precision fermentation, is currently working on beta-lactoglobulin, the main whey protein found in dairy, though the team is not sharing specific details when it comes to casein R&D, and says this is currently on the back burner.

The funding round was led by Sofinnova Partners, Sparkfood and Captech – and Bon Vivant plans to use the finances to speed up the production of its protein samples to accelerate commercialisation, support the construction of its R&D lab, and obtain regulatory approval in multiple countries.

The pilot facility is already being built and is set to be operational by Q2 2024, where its up to 40-litre fermentation tanks will help it produce large sample quantities for its clients. While Bon Vivant declined to disclose any names, its co-founder Stéphane McMillan says it is partnering with both leading food manufacturers and startups. (Last year, it teamed up with fellow French operation Abolis Biotechnologies to co-develop production methods and scale up manufacturing – but that collaboration has ended.)

He reveals that as a B2B ingredient supplier, Bon Vivant has already secured multiple partners and developed a few products with them, including yoghurts, ice creams and cream cheeses. “Combined with our highly productive process, we are confident we will be able to meet the volume our clients need and participate in the transformation of the industry,” McMillan tells Green Queen.

The company says it has no plans to introduce a consumer-facing brand. “Since day one, we were convinced that to have the most impact, we need to work hand-in-hand with the food [manufacturers] and help them reduce their environmental footprint,” he explains. “We know how to produce animal-free proteins. They know how to create delicious dairy products. So it is better to join forces to tackle climate change, with its huge stakes.”

Regulatory approval for animal-free whey protein

Bon Vivant is aiming for FDA approval in the US by 2025, which will be followed by regulatory filings in other locations. In the EU, many products made from precision fermentation are classed as ‘novel foods’ and require regulatory clearance, which can be a lengthy process. So far, no precision fermentation company has cleared this process in the EU.

In the US, three companies have obtained GRAS (Generally Recognised as Safe) status under FDA safety guidelines. These include Californian pioneer Perfect Day, and Israeli producers Remilk and Imagindairy. Is that a factor in why Bon Vivant is choosing to begin stateside?

“The EU’s standards are really high, so indeed it takes more time compared to the US,” notes McMillan in reference to the bloc’s novel food regulatory framework. “Still it’s not the only factor: market readiness to innovation for example is another one.” In March, a study by Perfect Day, Cargill and the Hartman Group found that 77% of US adults who are aware of precision fermentation are likely to purchase such products.

“In any case, Europe has an amazing role to play in precision fermentation, because we have a lot of knowhow, leading fermentation companies, production capacity already installed, etc.,” says McMillan. “But we need to make sure that we support the innovation in precision fermentation to make sure tomorrow’s champions will be European and that we don’t end up buying from non-European companies.”

In this vein, earlier this year, five precision fermentation producers formed an EU-wide coalition called Food Fermentation Europe to advance the development and regulatory approval of these ingredients. The focus is to “raise awareness and build a supportive, forward-looking policy framework for fermentation food and food ingredients in Europe” and advocate for a “predictable, non-discriminatory and market-based regulatory framework for fermentation food and food ingredients”.

Precision fermentation’s rise and climate credentials

“We are very proud of this new stage in the development of Bon Vivant, which enables us to welcome leading investors from the biotechnology and agri-food industries to our capital,” McMillan says of the investment. “This round of financing confirms the growing demand for precision fermentation as a solution to the tremendous challenges the agri-food industry, particularly the dairy industry, is facing.”

The news comes days after fellow European precision fermentation dairy producer Vivici announced it had scaled up its platform to produce beta-lactoglobulin (the same protein Bon Vivant is currently focusing on), with an eye towards US regulatory clearance next year. Beta-lactoglobulin is also the protein commercialised by Perfect Day and Remilk.

According to the alternative protein think tank the Good Food Institute, the fermentation sector has seen an investment of almost $4B to date, with at least 136 companies across the supply chain working on fermentation-based alt-protein as of 2022 – 62 of these are focused on precision fermentation.

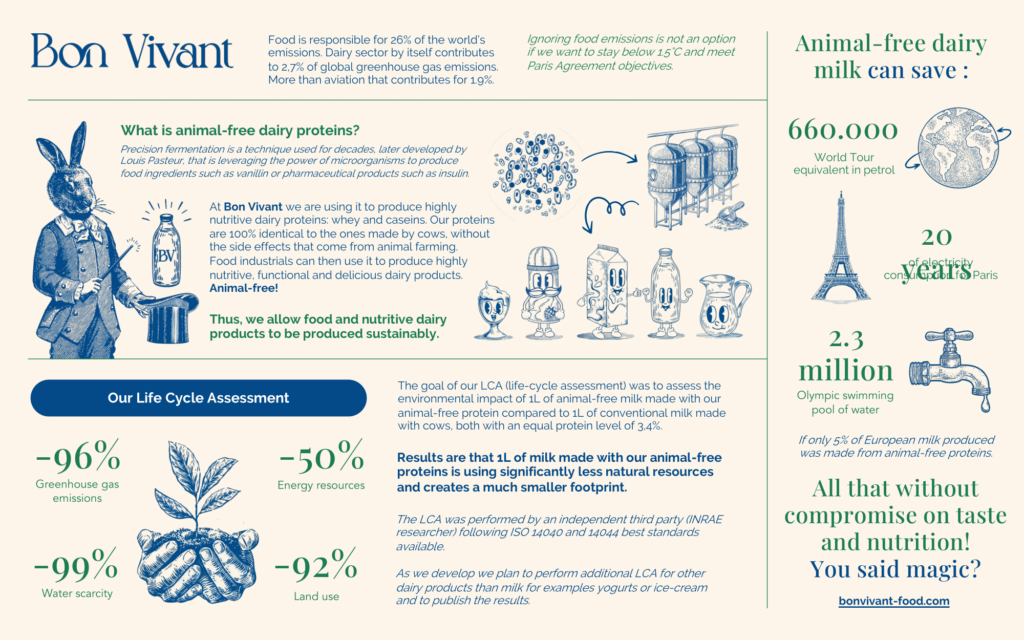

These animal-free proteins can have a much lower impact on the environment than traditional dairy. To calculate just how much, Bon Vivant commissioned a life-cycle assessment (LCA) in 2022 for its whey protein, which the company says was conducted independently according to ISO standards.

The LCA found that compared to conventional whey, Bon Vivant’s animal-free alternative emits 96% less carbon, and uses 99% less water and 92% less land. In terms of energy use, its precision-fermented dairy requires only half as much power as traditional dairy production.

According to the company, if only 5% of European milk was animal-free, it would save the equivalent of 660,000 tours of the world in petrol, 20 years of electricity consumption in Paris, and 2.3 million Olympic swimming pools of water (note: these numbers are estimates and not verified by Green Queen).

These figures aren’t a one-off. Perfect Day’s independent LCA, for example, presents similar results, finding that its precision-fermented whey has 91-97% lower greenhouse gas (GHG) emissions, 29-60% lower energy demands, and 96-99% lower water consumption than conventional whey protein.

Additionally, a non-company, independent LCA focused on the different forms of energy used to produce all kinds of animal-free proteins from precision fermentation in 2021 concluded that these proteins had a 53-100% lower environmental impact than their animal-based counterparts.