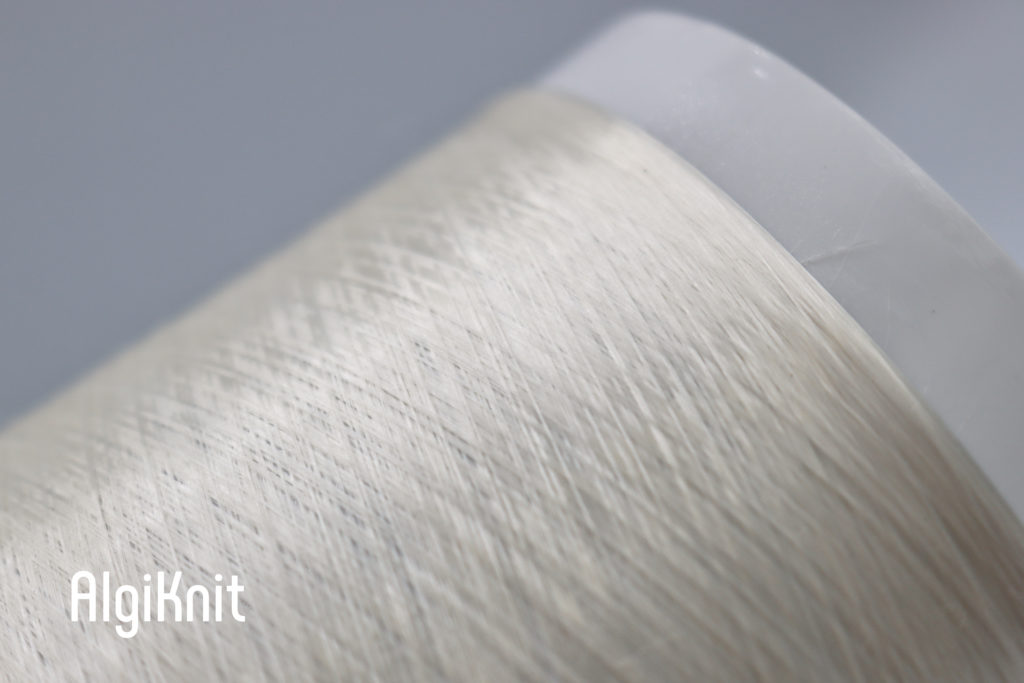

Seaweed Yarnmaker AlgiKnit Unveils New Facilities To ‘Help Cut The Fashion Industry’s Emissions In Half’

3 Mins Read

New York-based AlgiKnit has announced the opening of a new innovation hub. It is located in The Research Triangle, in North Carolina. The biomaterials maker will use the new space to scale production of seaweed-derived yarns. Pilot projects in conjunction with global fashion brands will begin in early 2022.

Earlier this year, AlgiKnit announced that it had secured $2.4 million in a bridge financing round. This supported continued technological development that has brought kelp-based yarn into reality. The new innovation hub will bring together all R&D and manufacturing capabilities in one location. The business development team will also be in place, to help scale and roll out production of the yarn.

Transforming the fashion industry

A recent report by the World Economic Forum pinpointed the fashion industry as the third-largest polluter. This included supply chains. Diving deeper, the report highlights that it is the creation of synthetic fibres that contributes to the majority of clothing’s carbon footprint. This is due to fossil fuels being used to manufacture synthetic fibres such as polyester and nylon.

A 2021 report published by Changing Markets revealed that 1.35 percent of global oil consumption is attributed to the production of non-renewable clothing fibres. For context, the research highlights that this is more than Spain’s total annual consumption. AlgiKnit aims to be the alternative.

“We know consumers need more cost-competitive, environmentally-sound material options that perform as well as conventional materials,” said Aaron Nesser, co-founder and CTO of AlgiKnit, in a statement. “The yarn we’re producing today has the look and feel of the natural fibres consumers are familiar with, plus all the makings of a no-compromise conscious material.”

Kelp is one of the most renewable natural resources in the world. It regenerates quickly and can be used across various applications. Clothing, footwear and accessories are all cited by AlgiKnit as being possible. As consumers start to opt for conscious fashion, the demand for alternatives to fossil fuel synthetics is increasing. This represented an opportunity for AlgiKnit to expand further than New York and into a space with similarly motivated businesses.

“North Carolina’s Research Triangle area is becoming a hub for big tech and life sciences, and we look forward to collaborating with other companies focused on scientific innovation and disruption,” said Aleksandra Gosiewski, co-founder and COO of AlgiKnit in a company statement. “We’re also excited for the opportunity to tap into the deep and diverse pool of talent and knowledge in the area to strengthen our scientific and engineering divisions.”

The Research Triangle is an area synonymous with future tech, as well as textile manufacturing. AlgiKnit plans to utilise the collaborative community for R&D progression and production scaling.

A wider movement

The fashion industry is facing change. Consumers are making their demands known and in turn, conscious manufacturers are implementing eco-friendly initiatives.

Pangaia recently announced a collaboration with Colorifix to negate toxic dyeing processes. It comes shortly after unveiling a range of sustainable denim pieces crafted using Himalayan nettle fibres and organic cotton, sourced in India.

Elsewhere, Lululemon is partnering with Genomatica to produce leggings made from bio-nylon. The goal is to replace all synthetic nylon with the plant-based alternative by 2030, as part of a circular economy commitment.

Lead image courtesy of Unsplash.