5 Mins Read

Worldwide, we consume around 7 million tons of chocolate every year. But as with other sectors of the food industry like meat and dairy, mainstream chocolate is under a lot more scrutiny these days for unsustainable production methods and unsavory labor practices. In response, a number of startups have surfaced with alternative ways to satisfy the world’s enormous appetite for chocolate.

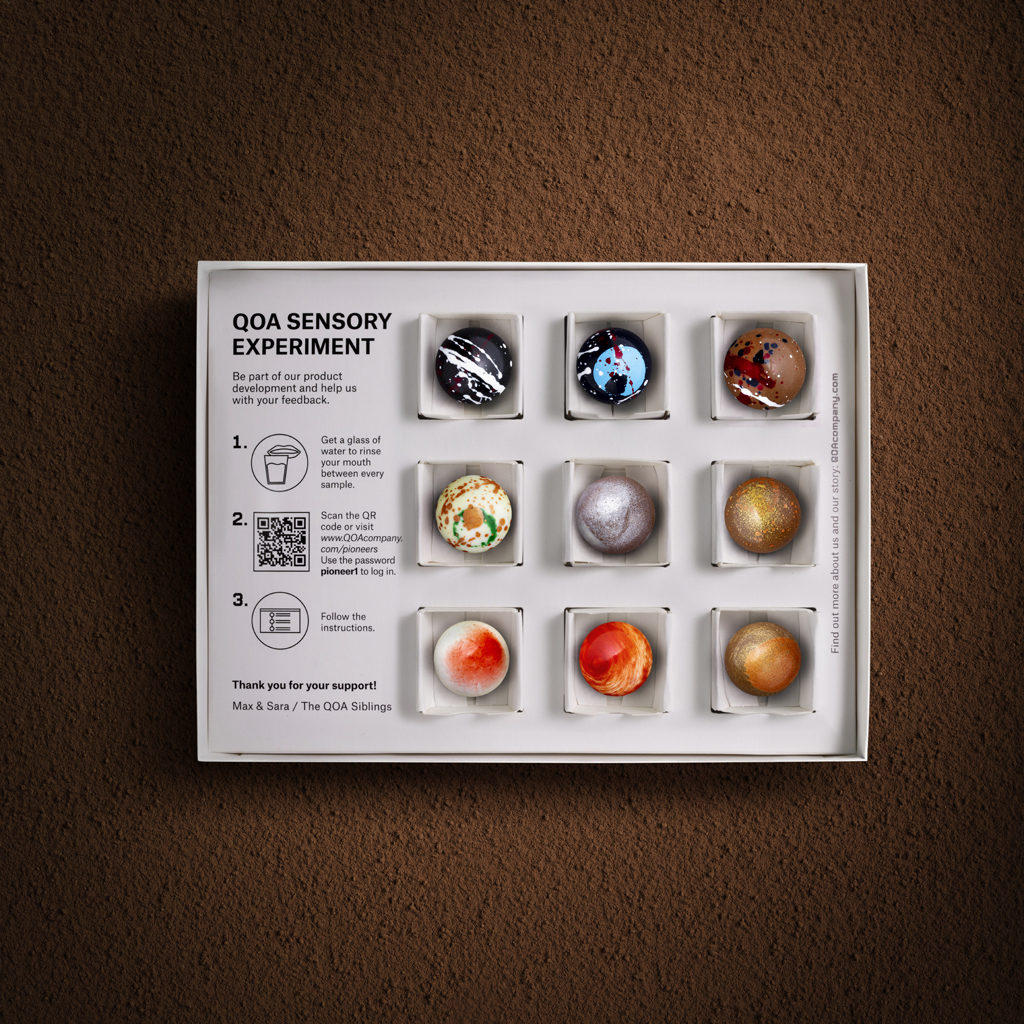

One of those companies is Munich, Germany’s QOA, launched earlier this year by brother/sister duo Max and Sara Marquart (pictured above). Currently a part of Y Combinator’s 2021 cohort, QOA aims to combat some of the biggest challenges in mass-market chocolate production by removing one of its most controversial ingredients: cocoa.

“We are the first 100 percent cocoa-free chocolate on the market,” Max explained over a recent call to Green Queen.

Chocolate without cocoa?

To those that don’t hold degrees in food science (which is most of us), producing chocolate without cocoa might seem an impossible task at first. But QOA has found a way to do exactly that using a precision fermentation method that recreates the composition of cocoa using other food materials. The process is akin to brewing beer (and one popularized by the likes of Perfect Day, which makes dairy alternatives).

For its cocoa-free chocolate, QOA analyzes various food byproducts to see which ones can be combined to match the flavor profile of cocoa. An example of this is the leftover residue from the production of olive, grapeseed, or sunflower oil. Fermenting these ingredients gives them what cofounder Sara calls “the perfect grounds for these microorganisms to grow and give us the building blocks to make our chocolate.” Once fermented, the ingredients can be roasted like a regular bean and included in chocolate. The end product is completely vegan as well as gluten- and dairy-free, and non-GMO. (Currently, it still contains sugar.)

Sara, a food scientist, previously worked for Seattle, Washington-based Atomo Coffee developing molecular coffee without the coffee bean. “I was always keen on cocoa and chocolate,” she explains.

Max, a materials scientist who has launched multiple startups and advises corporations on how they can benefit from relationships with startups, brought his expertise in business to the equation when the two decided to launch QOA. “She’s a fantastic scientist and I know how to grow a company,” he says.

The two started work on the company earlier this year, making the chocolate at home and eventually applying to and getting accepted by the prestigious Y Combinator accelerator. Currently, QOA has six employees and, according to the Marquart siblings, is manufacturing 10 kilograms of their cocoa-free chocolate per day.

However, QOA’s founders stress that their process isn’t necessarily about replacing all chocolate with a lab-grown substitute. At the heart of the company’s ambitions is a larger goal to address, according to Max, “the issues that we are currently seeing in the cocoa supply chain.” By that, he means the unsustainable nature of current cocoa production, which comes with significant environmental and human consequences.

The Cost of the Average Chocolate Bar

Roughly 70 percent of the world’s cocoa beans are grown in West Africa, largely in Ghana and Ivory Coast. The region has been identified as a “climate-change hotspot” by the United Nations and is expected to experience higher temperatures and longer dry spells in the future. These among other factors will heavily impact crop yields and quality, not to mention the livelihoods connected to those things.

Meanwhile, traditional cocoa production is a highly resource-intensive process that requires enormous amounts of water and is also the cause of much deforestation. Max notes that 1 kilogram of chocolate can produce up to 90 kilograms of CO2, largely from deforestation.

Cocoa production has also historically been linked to human rights abuses and child labor. Major producers of mass-market chocolate, including Hersey, Nestlé, and Mars, cannot guarantee their chocolates were produced without child labor, according to a well-known report from The Washington Post. The report also noted that 20 years after promising to wipe out child labor, most of these companies still can’t trace where much of their cocoa come from.

Needless to say, a company like QOA can’t single-handedly end child labor or deforestation. It can, however, provide a path to a different way of producing chocolate for the masses — one that doesn’t rely so heavily on unsustainable and ethically dubious practices.

Cocoa-Free Chocolate by 2035

One of QOA’s eventual aims is to get the chocolate industry to a point where mass-market products (such as your average Mars or Hershey bar) are regularly made with fermentation technology as opposed to traditional methods. Real cocoa beans farmed in the traditional manner would be reserved for ultra-high-end products and produced in much smaller quantities, decreasing the planet’s reliance on this method. QOA hopes to have replaced “a big chunk” of the conventional chocolate market by 2035.

Near-term goals for the company include working with chefs and bringing its own brand to market starting in high-end chains and coffee shops. A longer-term aim is to turn QOA into a B2B play, where the company collaborates with the world’s major chocolate producers (Mars, Nestlé, etc.) to produce chocolate without the cocoa at commercial scale. While he wouldn’t name specific companies, Max noted that QOA is already partnering with companies in this area.

Before any of that can happen, though, QOA must first prove to the average person that chocolate made without cocoa can still be delicious. That’s been a work in progress since the Marquart siblings began. Sara notes that they shipped their first prototype in May of 2021 to 40 people, who on average rated it 4.9 out of 10. Reception was “more on the hate side than the like side,” she says. “I went back to the lab and we worked harder, we also hired people.” QOA shipped a second prototype at the end of July and nabbed an 8.1 out of 10 for their efforts. The company also took the prototype to a panel of sensory scientists and asked them to differentiate between real chocolate and QOA’s lab-grown version. The scientists couldn’t.

Investors have been equally enthusiastic about QOA’s potential, and the company boasts a list of angel investors that currently includes Indiebio advisor and cofounder Ron Shigeta, Soundcloud founder Eric Wahlforss, Michael Sidler of Redalpine, Fredrik Jung-Abbou, Co-Founder of Kry, and Nucleus Capital’s Maximilian Bade, among others.

Right now, consumers can sign up via the company’s website to apply for a “test kit.” So far, QOA has shipped 200 boxes to people in the U.S. and Europe. “It’s getting amazing feedback so far,” says Max.

Lead Image Courtesy of QOA.