4 Mins Read

A team of students, known as Legendary Vish, are now developing 3D printed plant-based salmon. After working on 3D printing processes for medical technologies as a part of their doctorate projects, the group began modifying the technology to print plant-based proteins and binders in a structured seafood fillet format, something that most vegan seafood alternatives on the market have yet to achieve. Their goal is to accelerate development and scale-up production by 2022 to offer a healthy, tasty and sustainable substitute for different types of seafood.

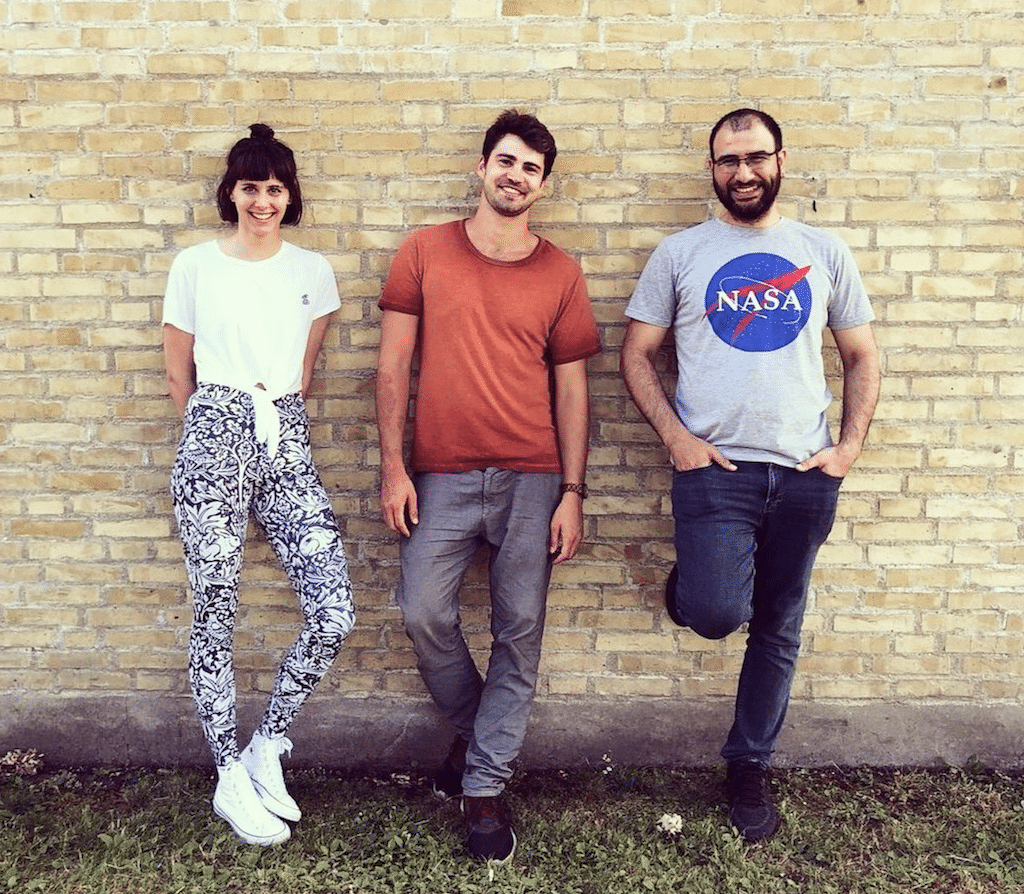

Robin Simsa, Theresa Rothenbücher and Hakan Gürbüz are a team of students developing 3D printed plant-based cuts of seafood. Based out of Vienna, the team came together in 2017 under the European Union-backed research project Training4CRM, and started to explore using 3D printing technology to create alternatives for seafood that could mimic the complex structure of cuts of fish, such as salmon and tuna.

“We saw that in the plant-based seafood market, there are currently mainly unstructured products, such as fish sticks or burgers,” Simsa, the CEO of the startup, told FoodNavigator. “However, products with a more complex structure such as salmon fillets can not be found on the market right now.”

Plant-based brands such as Good Catch, which recently reeled in an impressive line-up of celebrity investments, and Swedish startup Hooked, who are creating vegan shredded salmon currently rely on classical extrusion techniques to create products that can mimic the texture and taste of deconstructed fish.

Instead of using extrusion, which is commonly used to create plant-based meat and seafood alternatives, the group says that their use of 3D food printing can more accurately replicate the format of salmon fillets, which can then be used to make plant-based versions of sushi, sashimi or smoked salmon.

“With this special process, we achieve the complex appearance of our salmon fillets, which show the realistic distribution of orange/red meat tissue and white connective tissue,” explained Simsa in conversation with FoodNavigator. Legendary Vish plans to use mushroom and pea protein, as well as starch, agar agar and plant-based omega-3 ingredients such as nut or seed oils in their first 3D printed salmon prototype.

For the group, the ultimate mission is to develop an alternative that can replace the need for unsustainable industrial fishing. Due to the rising demand for seafood – at a rate of 3.6% year-on-year since the 1960s and mostly driven by Asia – fish populations are predicted to be wiped out by as soon as 2050.

Aside from overfishing and greenhouse gas emissions from the use of fishing vessels for wildcatch and feed in aquaculture pens, the seafood industry is also responsible for enormous amounts of plastic pollution, with almost 50% of ocean plastic coming from discarded fishing nets and gear.

Not to mention, the fishing industry is mired with traceability and mislabelling issues as well as disease outbreaks. In the midst of the current coronavirus pandemic, seafood production in China is currently battling the spread of Div1 shrimp virus disease in cramped aquaculture pens.

Looking ahead, Legendary Vish hopes to not only create successful plant-based 3D printed fish substitutes with production planned for 2022, but to become a 3D food printing technology supplier for other companies looking to create alternative proteins. After their targeted commercialisation in Germany, Austria and Switzerland, the group hopes to expand across Northern Europe.

This isn’t the first time that entrepreneurs have capitalised on 3D printing technology to create cuts of protein. Spanish food tech Novameat, for instance, recently unveiled version 2.0 of their 3D printed“steak”, described as the most realistic product yet to mimic the texture and appearance of a cut of beef steak.

Other startups have harnessed 3D printing and combined it with personalised nutrition aspects, such as Tokyo-based Open Meals’ 3D printed pixelated sushi with added customisable nutrients suited for each diner. It is set to debut in their restaurant Sushi Singularity some time this year.

Amid the current coronavirus pandemic, alternative protein industry expert Olivia Fox Cabane believes that there is a huge potential for 3D printed proteins as a sustainable solution to the broken food supply chain. Not only would it help bolster food security and prevent external supply shocks, switching to alternative proteins would help to dramatically reduce humanity’s environmental footprint in the long-term, and also benefit the global environment as it would alleviate the need for traditional animal agriculture and its accompanied greenhouse gas emissions.

All images courtesy of Legendary Vish.